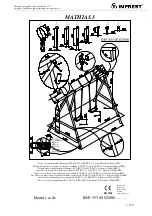

CH30-10 Swing Set Parts Identification Page

The Small Parts

Flat Washer

Loc Washer

Nyloc Nut

Hex Nut

T-Nut

Tap Bolt

Hex Bolt

Carriage Bolt

Set Screw with Allen Wrench

#14 Sheet Metal Screw

Lag Screw

#14 Truss Screw

2 ½” Self-Tapping Screw

Carabineer/Spring

Clip

Panel Clamp

Plastic Plug

CH Deck Plug

Pictures are not to up to scale. The purpose of this sheet is to give you a general idea of the shape and names

of the parts of your swing set.

Clevis with Key

Summary of Contents for CH30-10

Page 27: ......