Composite-ARF New Rookie

techsupport@composite-arf.com

4

The slot needs some explanation, too. The cut line is exact-

ly in the correct position so that the aileron slides under the

wing skin smoothly. If the cut was a few mm forward or

back, it would not work properly. So, make sure that the lip

is not damaged, and that the control surface slides under

this lip perfectly. It will NOT lock at any time, as long as the

lip is not damaged. If damage occurs, you can cut off 2-3

mm, but you should NEVER need to cut off more than this.

Servo Screws:

Secure the all the servos to the cnc milled plywood servo mounts using the 2.9mm ø x 13mm

long sheetmetal screws provided in the kit -

not

the standard screws supplied with your ser-

vos, as these are usually too small for the milled 2mm Ø holes.

Take Care:

Composite sandwich parts are extremely strong, but fragile at the same time. Always keep in

mind that these contest airplanes are designed for minimum weight and maximum strength in

flight. Please take care of it, especially during transport, to make sure that none of the critical

parts and linkages are damaged. Always handle your airplane with great care, especially on the

ground and during transport, so you will have many hours of pleasure with it.

To protect the finished paint on the outside of the model from scratches and dents during build-

ing, cover your work table with a piece of soft carpet, cloth or bubble-plastic. The best way to

stop small spots of glue getting stuck to the outside painted surfaces is to give the whole model

2 good coats of clear car wax first,

but

of course you must be sure to remove this 100% proper-

ly before adding any paint, markings or trim. Alternatively you can cover the majority of the fuse-

lage with the bubble-plastic used to pack your model for shipping, fixed with paper masking tape,

which also protects it very well.

Adhesives

Not all types of glues are suited to working with composite parts. Here is a selection of what we

normally use, and what we can truly recommend. Please don’t use inferior quality glues - you will

end up with an inferior quality plane, that is not so strong or safe.

1.

CA-Glue ‘Thin’ and ‘Thick’ types. We recommend ZAP, as this is very high quality.

2.

5 minute-epoxy (highest quality seems to be Z-Poxy)

3.

30 minute epoxy (stressed joints must be glued with 30 min and NOT 5 min epoxy).

4.

Epoxy laminating resin (12 - 24 hr cure) with hardener.

5.

Milled glassfibre, for adding to slow epoxy for strong joints.

6.

Microballoons, for adding to slow epoxy for lightweight filling.

It is very important to prepare all parts to be joined properly, by roughing up with coarse sand-

paper and cleaning both surfaces with alcohol/acetone or a similar solvent, before gluing

any

parts together.

When sanding areas on the inside of the fuselage to prepare the surface for gluing something

onto it, do NOT sand right through the layer of glasscloth on the inside foam sandwich! It is only

necessary to rough up the surface, with 60/80 grit, and wipe off any dust with acetone or alco-

hol (or similar) before gluing to make a perfect joint.

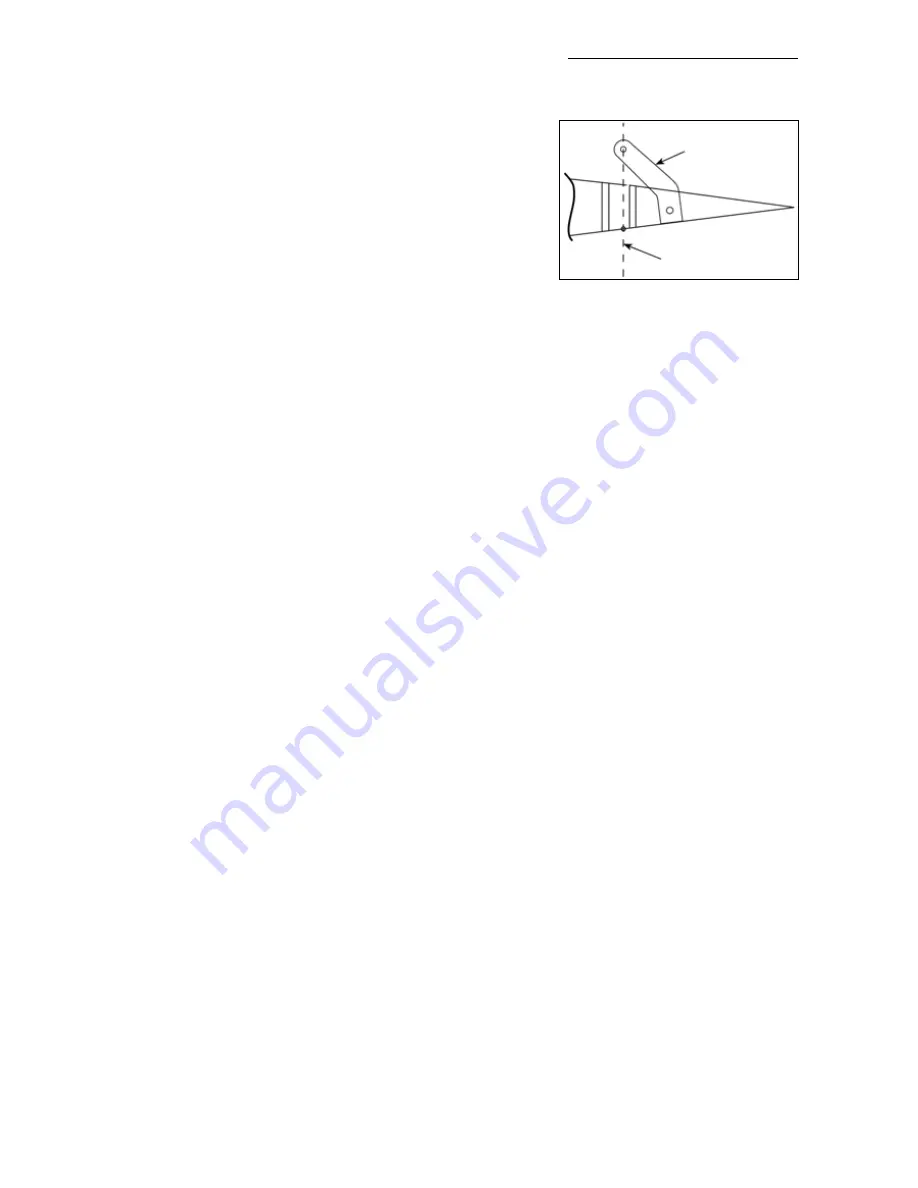

Centreline of hinge axis

Phenolic control horn