15

COMUNELLO

®Copyright 2014 - All right reserved

ENGLISH

TECHNICAL SPECIFICATIONS

Back-up Battery input:

24 V 7A/h max.

Flashing light output:

24 V 4 W max.

Operator outputs:

24V 1 x 50 W max.

Photocells power supply:

24V 5 W max.

Working temperature:

-20 ÷ + 50 °C

Radio receiver:

433 Mhz

Transmitters:

18 Bit or Rolling Code

Max TX codes stored in memory:

120 (CODE or PED CODE)

Board dimensions:

100x105 mm.

Maximum power consumption

150W

PRELIMINARY CHECKS

• Check that the product in the pack is intact and in good condition.

• Check that the place of installation is suitable and in compliance with the

minimum dimensions shown in FIG. 1.

INSTALLATION

• Drill the box in the four corners and then fix the control unit to the wall

(FIG. 2).

• Drill a hole in the underside of the box for the cable inlet. (FIG. 3)

The use of cable glands is recommended.

ELECTRICAL CONNECTIONS

CN1:

BATT+24V:

+24V Back-up Battery input

BATT-24V:

–24V Back-up Battery input.

LAMP+24V:

+24V Flashing Light Output.

LAMP-24V:

–24V Flashing Light Output.

MOT1+:

Operator 1 + Output.

MOT1-:

Operator 1 – Output.

CN2:

STOP:

Emergency stop input (NC)

GND:

Common GND input

FOTO+:

Photocells Control and Power Supply (24V 5W).

GND:

Photocells Control and Power Supply (GND).

FCC:

Operator Closing Limit Switch Input (NC).

GND:

Common GND input

FCA:

Operator Opening Limit Switch Input (NC).

DS1:

Safety Device Input (NC).

GND:

Common GND input

PP:

Pedestrian Pushbutton open-close command input (NO).

ANT-:

Antenna Ground Input.

ANT+:

Antenna Hot pole input.

CN3:

L:

230 V~ line input (phase).

N:

230 V~ line input (neutral).

TRANSFORMER CONNECTIONS

CN4 1st:

1:

230 V~ Transformer Primary Winding Input.

2:

230 V~ Transformer Primary Winding Input.

CN5 2nd:

1: Transformer SEC 1 Output 21.7V 7.5A no-load voltages.

2: Transformer SEC 1 Output 21.7V 7.5A no-load voltages.

FUNCTIONAL CHARACTERISTICS

AUTOMATIC OPERATION:

When either the remote or the low voltage pushbutton panel is used to

control the gate, operation is as follows:

the first command opens the gate until motor time elapses or until the gate

reaches its opening limit position; the second command closes the gate; if

another command is transmitted before motor time has elapsed or before

one of the two limit stops has been reached, the control unit reverses the

movement direction during both opening and closing.

STEP-BY-STEP OPERATION:

When either the remote or the low voltage control pushbuttons are used to

control the gate, operation is as follows:

the first command opens the gate

until motor time or until the gate

reaches its opening limit position; the second command closes the gate;

if another command is transmitted before motor time has elapsed or

before one of the limit stops has been reached, the control unit stops the

movement. Another command causes the gate to start moving again in the

opposite direction.

Step-by-step 1 operations:

When either the remote or the low voltage control pushbuttons are used to

control the gate, operation is as follows:

the first command opens the gate

until motor time or until the gate

reaches its opening limit position; the second command closes the gate;

if another command is transmitted before motor time has elapsed or

before one of the limit stops has been reached, the control unit stops the

movement during both opening and closing. Another command causes the

gate to start moving again in the opposite direction.

AUTOMATIC CLOSING:

The control unit can be set up to close the gate automatically without

sending any additional commands.

The selection of this type of operation is described in Pause time

programming mode.

PEDESTRIAN OPENING:

By means of the remote (CODE P. LED lit) the remote control makes it

possible to drive the Operator for a programmable time, typically to allow

pedestrian access.

EMERGENCY STOP INPUT:

The control unit allows the connection of an emergency stop pushbutton

(NC). Pressing this pushbutton irrespective of the current operating mode

of the control unit will cause immediate stopping of the gate movement. An

additional gate movement command will be valid provided the emergency

stop input is deactivated and, in any case, the control unit will execute the

gate opening cycle with 5 seconds preflashing.

IMPORTANT:

Jumper this input if it is not to be used.

PHOTOCELLS:

Photocells can be powered by and connected to the control unit in

accordance with directive EN 12453.

Tripping of the photocells during opening is disregarded, while during

closing it causes reversal of the direction of movement.

To allow operation in compliance with EN 13849-1, Category 2 a photocell

test is performed before each movement. The control unit enables the

movement only if the test is passed; if it is not, the control unit inhibits

all movements and an alarm condition is signalled by blinking of all the

programming LEDs on transmission of each command.

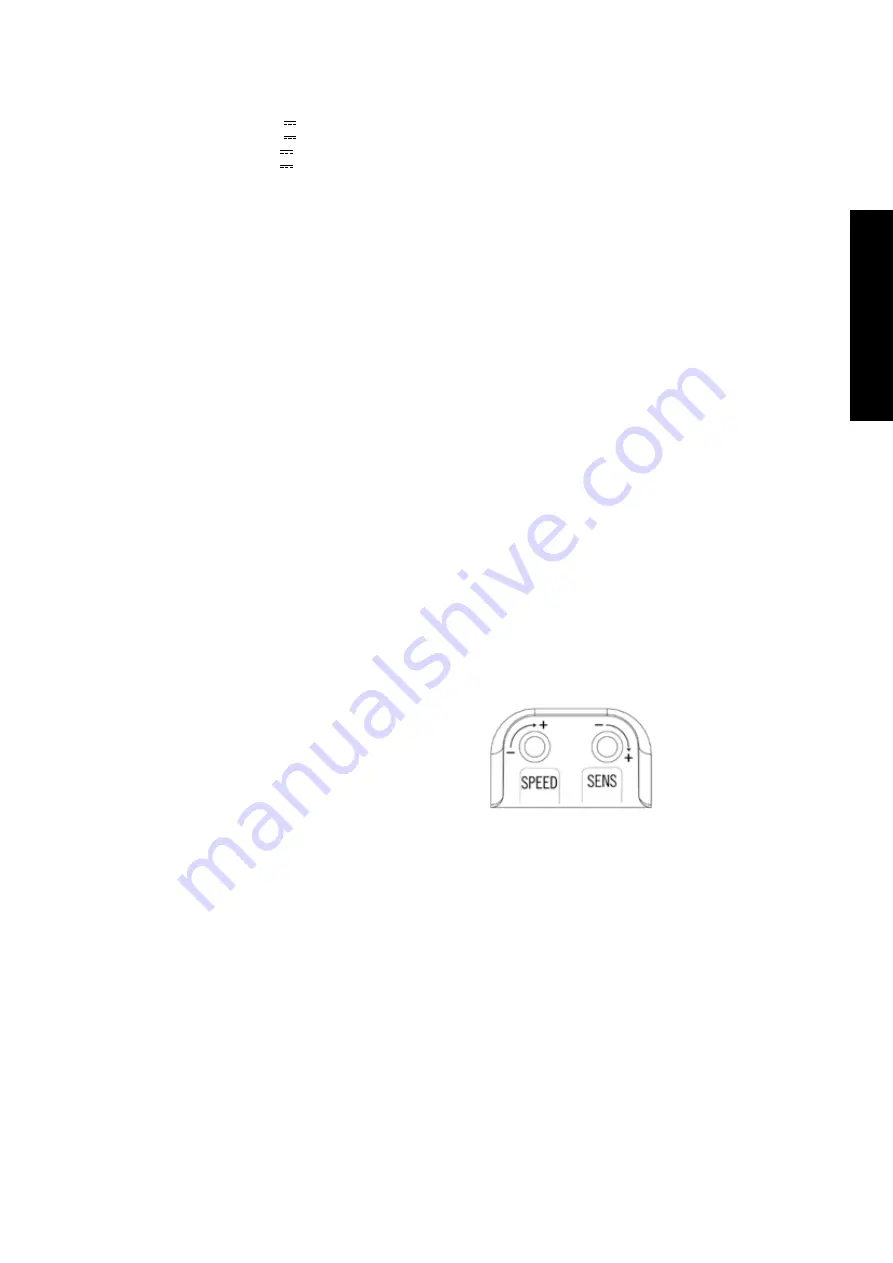

OBSTACLE DETECTION (SENS):

The electronic control unit is equipped with a “SENS” trimmer, completely

managed by the microprocessor, for adjustment of the opposing Force

required to detect the presence of an obstacle.

The adjustment can be made with a trip time from a minimum of 0.1

seconds to a maximum of 7 seconds.

IMPORTANT:

• If limit switches are connected to the control unit detection of an obstacle

will always result in movement reversal during closing and reversal for 2

seconds during opening.

• If there are no limit switches connected to the control unit detection of an

obstacle will always result in movement reversal during closing (except

in the final 5 seconds of the movement, when it will cause a Stop) and

reversal for 2 seconds during opening (except in the final 5 seconds of

the movement, when it will cause a Stop).

Obstacle detection system also works with automations without

encoder.

OPERATOR SPEED ADJUSTMENT (SPEED):

The electronic control unit is equipped with a “SPEED” trimmer for

operator speed adjustment, completely managed by the microprocessor.

Adjustment can be performed in a range of between 50% and 100% of