CONCEPT

CONCEPT

CONCEPT

CONCEPT

CONCEPT. Small Low Profile P

. Small Low Profile P

. Small Low Profile P

. Small Low Profile P

. Small Low Profile Powered Enclosure.

owered Enclosure.

owered Enclosure.

owered Enclosure.

owered Enclosure.

Installation Notes.

2

Installing the Small Low Profile Powered Enclosure.

Electrical AC Mains Power connection.

In countries where the module is supplied without a mains power cord, a suitable mains power cord for connection to the 240V

AC Mains supply must be installed by a suitably qualified electrician or technician.

1. Strip 30mm of the sheath from the end of the power cord. Trim 5mm from the ends of the Active and Neutral conductors so

that the Earth conductor remains slightly longer.

2. Strip 5mm of insulation from each of the conductors and feed at least 100mm of the power cord through the AC mains cable

entry hole in the bottom of the chassis.

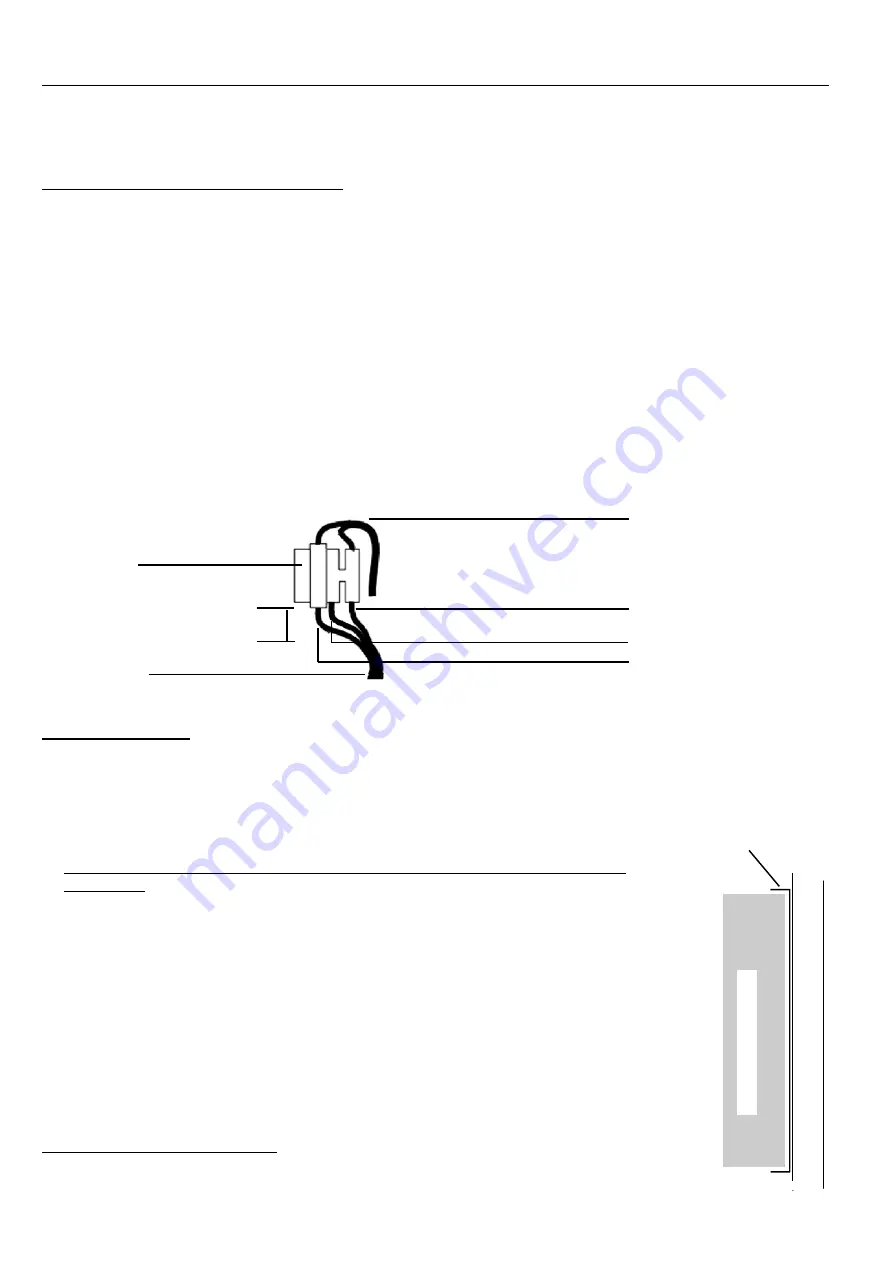

3. Terminate the power cord in the terminal and fuse block as illustrated in Diagram 1 below. Note that the Active wire is

always connected into the termination nearest to the fuse.

4. Determine the appropriate length of power cord between the terminal block and the cable entry hole. (Approx. 100mm)

Working from the bottom of the chassis, fit the plastic grommet (supplied) around the power cord and apply pressure to both

sides of the grommet to clamp the cable. The grommet can now be inserted into the AC mains cable entry hole.

IMPORTANT NOTE: An AC Mains socket-outlet shall be installed near the equipment and shall be easily accessible for

connection of the mains power cord.

Transformer

input connection.

Neutral

Earth

Live (Active)

Diagram 1.

25mm

Mounting the Unit. See Diagram 3 on the following page.

1. Installation environment should be maintained at 0º to 40º Celsius and 15% to 85% Relative

humidity (non-condensing)

2. The enclosure must be secured to a flat, vertical surface using fasteners through the four

“keyhole” mounting holes in the chassis. We recommend mounting the enclosure with the

Mains Cable entry and Transformer at the bottom as shown in Diagram 3.

3. When mounting this product onto flammable surfaces, a fire protection backplate MUST BE

INSTALLED.

(See Diagram 2)

Any Conduit entry points that have had the knockout

removed but will not be used, must also be resealed using 25mm Conduit Plugs.

4. Fit the tamper switch into the tamper switch bracket. Install this assembly by placing the

tamper switch plunger in the hole provided in the base, and the tongue on the bracket through

the slot provided in the lip in the top of the chassis.

5. The Battery is normally installed in the bottom of the enclosure.

(See Diagram 3)

An

optional Battery retaining bracket (Part Number: 926005) can be used if the enclosure is not

mounted as recommended in Step 2.

6. The metal chassis is electrically earthed and the Circuit Board Assembly is electrically

isolated from the chassis. When mounting and wiring the Module, the Installer must ensure

that this isolation is maintained.

Connecting Power to the PCB. See Diagram 3.

1. The connection between the AC mains transformer output (A) and the “AC” Input

connections on the PCB (B) is pre-wired in the factory.

Fuse. 1.0 Amp

Slow Blow

M205 (20mm)

AC Mains cable.

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

1234

Flammable Mounting Surface.

Diagram 2.

Refer to “Mounting the

Unit”, Step 3.

Fire Protection

Backplate.

Equipment Enclosure.