2

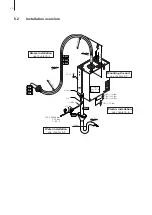

Steam line with fixed piping

For steam lines with fixed piping, the same instructions apply to the laying of the piping as already

described. The following additional notes should be observed:

– The

minimum internal diameter of 22 mm, 30 mm or 45 mm

respectively should be applied

over the whole length of the piping.

– Use exclusively Cu pipe or stainless steel (min. DIN 1.301).

– To minimize the condensate formation (=loss), the steam pipes must be insulated.

– The

minimum bend radius

for solid pipes is

4-5 x internal diameter

.

– Connection of the steam pipes to the steam distribution pipe and steam generator is effected by

means of short lengths of steam hose secured with hose clamps.

–

Important!

Allowance must be made for a

pressure loss of 10 mm water column (approx.

100 Pa)

per meter length or per 0° bend.

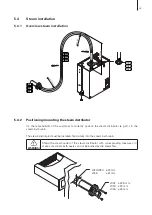

5.4.4

Inspecting the steam installation

Use the following check list to ascertain that the steam installation was performed correctly:

– Steam distribution pipe

Steam distributor correctly positioned and secured (screws tightened)?

Steam outlet of the steam distributor with corresponding measures shielded to make sure

steam bath users can not be burned by the steamflow

.

– Steam hose

Maximum length of m?

Minimum bend radius of 300 mm (- x internal diameter with fixed piping)?

Have the instructions for hose positioning been followed?

Steam hose: no sagging (condensate pocket) or condensate drain with siphon (hose bend

with a minimum diameter of 200 mm) installed at the lowest point?

Rigid steam lines: properly insulated? Correct installation material used? Minimum internal

diameter maintained?

Steam hose(s) securely attached with clamps?

Heat expansion during operation and shortening of the hose with ageing taken into considera-

tion?