R

3-10

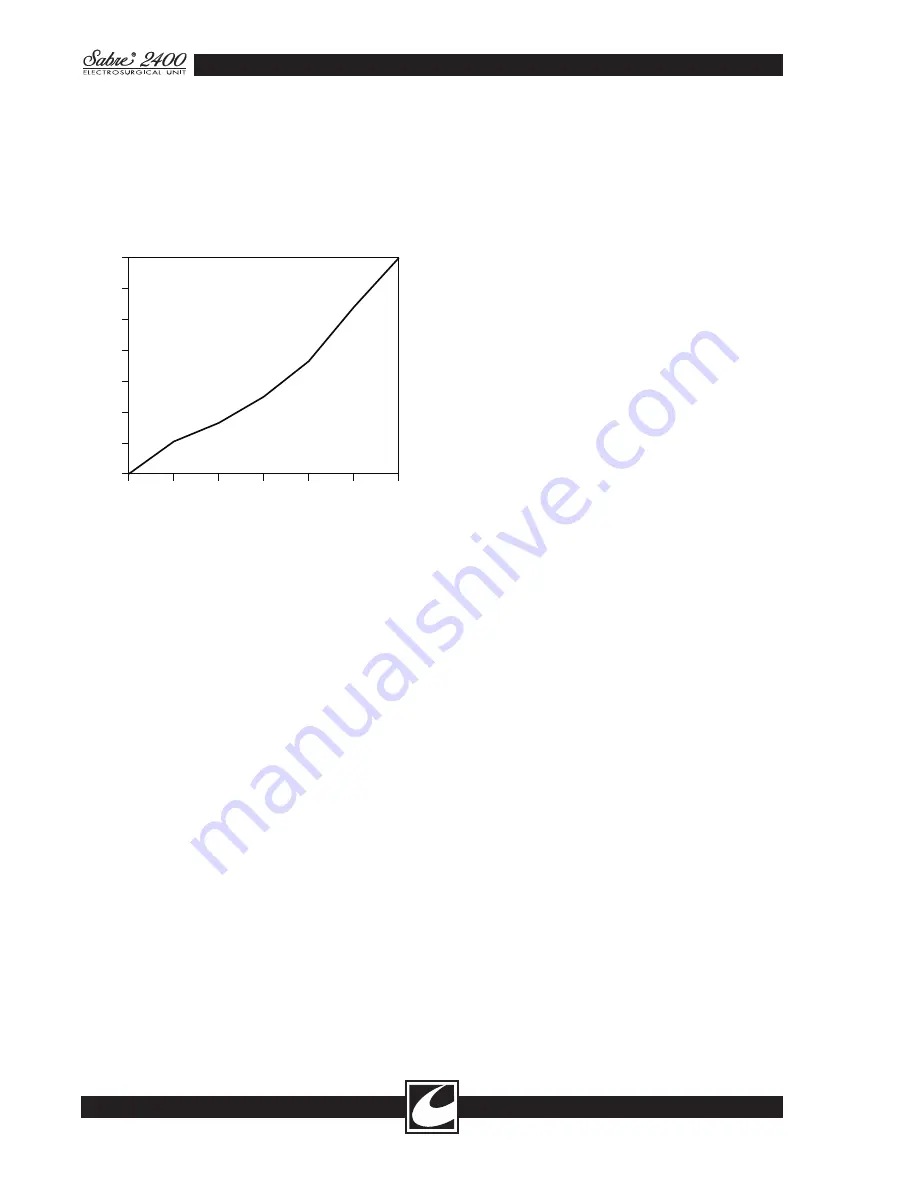

Figure 3.1 shows the approximate resistance vs.

number of illuminated bars in the resistance indi-

cator. If no bars are lit, then the resistance is less

than approximately 10 ohms, if 10 bars are lit,

the resistance is greater than approximately 150

ohms. It is not possible for just 1 or 9 bars to be

lit.

In Dual Foil Mode, the Resistance Indicator will

be illuminated to indicate pad resistance in the

range of 10 to 150 ohms. At just over 10 ohms,

the two left bars are illuminated. As VARM

increases, additional bars are illuminated in pro-

portion to VARM, progressing to the right, until

the resistance approaches 150 ohms, where eight

bars are illuminated. When resistance exceeds 150

ohms, all ten bars are illuminated. Whenever a

Return Fault condition exists, all illuminated bars

will flash, but resistance is still displayed as above.

In Dual Foil Mode, the microprocessor declares

a Return Fault if R

LOAD

is less than 10 ohms or

greater than 150 ohms. If VARM is within the

allowed range, then the Return Fault Indicator

will turn off when the Monitor Set Key is

pressed, and the present value of VARM is stored

for reference. A new Return Fault will be declared

if pad resistance rises about 20% above this stored

value or goes out of the allowed range.

A rise of approximately 20% over the resistance

of a Return electrode in full contact with a patient

indicates significant electrode detachment. A

Return Fault declared in this case will NOT auto-

matically be cleared if the patient resistance drops

back to near the stored value. The Monitor Set

Key must again be pressed to register the staff's

satisfaction that the electrode attachment is safe

before turning off the alarm.

Because patients’ and return site resistances vary

over a considerable range, it is not safe to assume

that any in-range resistance indicates safe elec-

trode attachment. For example, a poorly placed

electrode on a well-perfused site can show the

same resistance as a safely attached electrode on

adipose tissue. Yet the poorly placed electrode

could still result in a burn due to low contact

area. The clinical staff is responsible for the final

judgement of safe return electrode placement.

FIGURE 3.1

The VARM voltage is read by channel #0 of the

analog to digital converter (A2U16) to an accu-

racy of 10mv. This voltage is directly proportional

to pad resistance and is used by the program to

test and display the pad resistance value. This

value is then processed along with the VARM val-

ues for 10 and 150 ohm return circuit resistances

stored in the EEPROM during the last pad cali-

bration to evaluate the current.

The Return Fault process works on a 50-point

(0.6 sec) minimum average VARM value. If

Single Foil Mode is selected, the microprocessor

will declare a Return Fault when VARM indicates

that pad resistance is 10 ohms or greater. The

Resistance Indicator is always dark in this mode.

150

130

110

90

70

50

30

10

2

4

6

8

RESISTANCE (OHMS)

RESISTANCE BARS

Summary of Contents for Sabre 2400

Page 1: ...Operator Service Manual R ...

Page 6: ...R This page intentionally left blank ...

Page 16: ...R 1 10 Figure 1 2 Blend Cut Load Regulation Figure 1 3 Monopolar Coagulation Load Regulation ...

Page 18: ...R 1 12 This page intentionally left blank ...

Page 41: ...R 3 13 Figure 3 2 Waveform Generator Output ...

Page 42: ...R 3 14 Figure 3 3 RF Output Waveforms ...

Page 43: ...R 3 15 Figure 3 3 RF Output Waveforms ...