11.

Now

pre

pare the Slater’s

w

hee

ls. Rem

ove a

ny pl

astic

flash or

mould

ing

p

ips

fro

m the b

ack

s of th

e wheel

b

y ru

bbing

them

fla

t o

n a

piece o

f

fine e

mery

cloth (this

flash can

some

tim

es

interfe

re w

ith

the p

lung

er pickups). T

he cra

nkp

in

screw

head

needs to b

e f

lus

h w

ith

the b

ack

of t

he w

hee

l (it

ma

y interf

ere w

ith the

shou

lder of the b

earing o

th

erw

ise) so

it

will be necessar

y to drill a

countersink

hole. Us

e a 2.5mm

drill in a hand held pin ch

uck. Drill gently

and ke

ep checking

with

the

head

of the

screw

until

the ho

le is the

corre

ct

depth

.

Th

e scre

w is d

esi

gned

to se

lf t

ap in

to the

plas

tic

and t

hen

lock itsel

f. I don’t trust this and

prefer to screw

it in until the

head is just proud of

the w

heel b

ack

. I then fill the

counte

rsink h

ole w

ith

Ara

ldite

and then screw

it in until it

locks. Le

ave the

whee

ls un

til the Ara

ldite ha

s s

et and th

en

clean o

f a

ny e

xcess Araldite

by

rubbin

g the

whe

el

on the

emery

cloth

. This sh

ould leave the

scre

w h

ead

em

bed

ded in

Araldite and

p

rev

ent

the po

tential prob

lem of

the scre

w

turning

w

hen

yo

u are tr

ying

to

u

ndo

the cran

kp

in nut.

Y

ou m

ay f

ind

th

at the s

qua

re axle e

nd is a tigh

t f

it into the

centre of th

e w

he

el a

nd

th

is needs correcting

. W

ith

a f

ine

fla

t

file ge

ntly dress

each o

f th

e f

our

sides o

f the

a

xle

end

. I find i

t

helps to

lay the

bottom f

lat

of th

e axle end

onto th

e edge

of a

block

of w

ood. This help

s m

e k

eep

the f

ile parallel as I

file the

top fla

t. O

ffe

r the

axle end in

to the w

hee

l centre

an

d repeat i

f

nece

ssary

. Y

ou are

aimin

g to get a

gentle

push

fit bu

t w

ith

no

roc

king

or m

ove

me

nt on

the

squa

re. A go

od gu

ide is to

get it

so that you can rem

ove

the

whee

l fro

m the

axle with ju

st your

fing

er nails arou

nd the st

eel tyre. If

yo

u have

to

g

rip the

ty

re

with

your f

inger ends to

pull it off yo

u w

ill find it diff

icult to

rem

ove the w

hee

ls to p

aint th

e chassis.

Once h

app

y f

it

the

wheel sets int

o the ch

assis

remem

bering to

quarter the

whee

ls (the cran

kp

ins on on

e side sho

uld

lead t

he othe

r by

90°).

Ch

eck th

at th

e cha

ssis sit

s leve

l on a

fla

t su

rface

with

out

rock

ing (t

wist slig

htly

if re

quire

d). The

centre w

hee

ls a

re

raise

d sligh

tly

to preven

t th

e loco

rockin

g on

uneven

track

and so th

ese w

hee

ls w

ont

revolve if th

e chassis is push

ed

alon

g th

e be

nch.

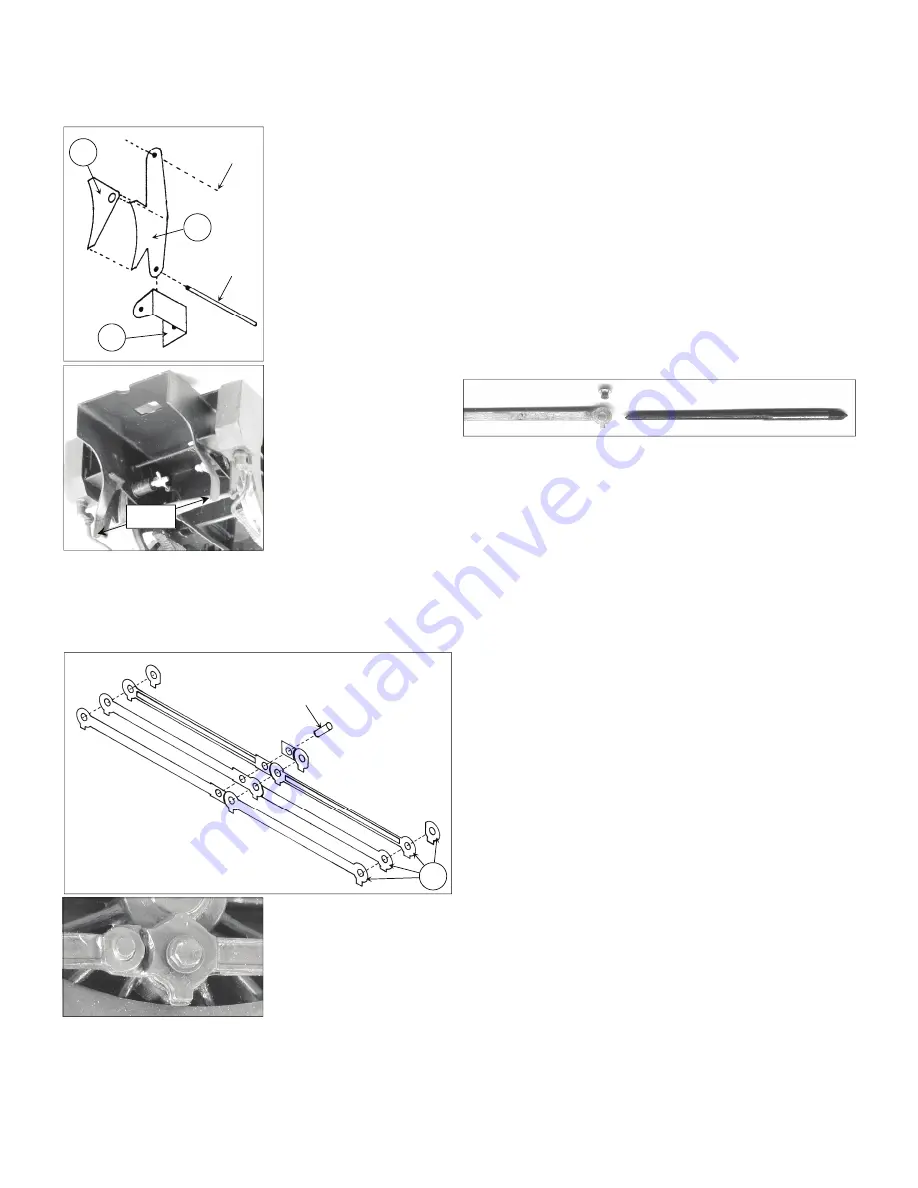

12.

Make

up the cou

plin

g rods (p

arts 55) by

lamin

ating

togeth

er the three

parts

of ea

ch section

an

d then

fitting

the

separa

te bosses. The

ro

ds are desig

ned

to be

jointed b

y

overlapping

on th

e ce

ntre

crank pin. A sh

ort length

of

1.8

mm

copp

er

ro

d is fitte

d

into th

e couplin

g rod at

the

section that cosm

etically

represents the

prototyp

e

joint.

24

Copp

er rod to

fo

rm

joint pin

PAGE 14

No

w op

en

out the

cran

kp

in ho

les in the rod

s to

accept the

brass top h

at b

earing

bushes. T

his is b

est d

one

w

ith a

tape

red

broa

ch or

tape

red e

ngi

nee

rs re

ame

r (I ha

ve on

e tha

t

tapers f

rom

3mm

to 2m

m an

d is 40mm

long

(see y

ello

w

page

s fo

r a good

e

ngi

neers too

l m

erch

ant they ar

e not

cheap

but w

ill last a lifeti

me).

W

ith the

ream

er gently w

ork

fro

m both

sides of the

rod un

til the b

ush is a s

moo

th f

ree

fit into

the

hole.

No

w f

it the rods and

ch

eck th

at the cha

ssis runs f

ree

ly and

that the w

heel

s w

ill turn w

ithout binding. If

yo

u do have

a

pro

blem

gently

revolve t

he

whee

ls w

ith

your f

ing

er tip

until

you h

it t

he tig

ht sp

ot th

en ch

eck th

e ro

ds. Y

ou

shou

ld find

that one rod still

mo

ves freel

y on the crank

pins a

nd

this side

is OK. Y

ou

should f

ind

th

at th

e rod

on th

e othe

r side

is tig

ht

on

the

crank p

ins a

nd this is

whe

re

the

proble

m is. Norm

ally

the pro

ble

m is a cran

kpin scre

w that is

not squ

are in the

whe

el (unle

ss

you

have

reamed

th

e hole

in the

rod o

ut o

f

squa

re).

W

ith

a ro

und

file

gent

ly f

ile o

val

the h

ole in

the r

od

until it f

its

fre

ely

onto th

e crank

pins an

d then ref

it t

he rod

and

chec

k th

e chas

sis again

.

At this stag

e don'

t w

orr

y abo

ut slig

ht tight

spots.

If y

ou ca

n

push the

chassis

along the

bench

w

itho

ut t

he w

heels

skidd

ing a

long

then

all is OK

. As the

whee

ls are

best

remo

ved fo

r p

ainting

th

e chassis th

e chan

ces ar

e that the

y

will not go

back on in th

e same

place. The

correct point to

mak

e f

ina

l a

djustm

ent

s is after pa

inting and

fitting pick

ups

but

be

for

e fitt

ing th

e mo

tor.

If

you

have

file

d a cra

nkpin

ho

le

in the r

ods ov

al it is

w

ort

h m

ark

ing this wheel

so that

you

can

match

them

up ag

ain on

re

assem

bly. No

w rem

ove the ro

ds

and

p

lace sa

fe

ly to

one si

de.

Using

long

nosed

plie

rs

ben

d sets into

the fr

ont

end

gua

rd iron

s so that

they

are

32m

m (r

ail ga

uge

) ap

art.

13.

Tak

e

the

brake

han

gers (parts

56)

and

solder brak

e blo

cks

(parts

57)

to them. Ma

ke

u

p thre

e

left

hand

and thre

e righ

t

hand

sets

. Th

read

leng

ths o

f

0.9

mm

brass w

ire acr

oss

the ch

assis and sp

ot solde

r

to

the in

side

o

f

th

e

sidefr

am

es. Fold u

p

the

bra

ke ha

nger

b

ra

ck

ets

(parts

58

) th

en th

re

ad

bra

cket an

d brake ha

nger

onto the w

ire. Solder th

e

brac

ke

t to

the sid

e f

ram

e

and lin

e up b

rake b

loc

k just

clear of th

e whe

el and

solder to

wire. I f

ind it helpfu

l

to hold

the b

rak

e ha

nger

usin

g a min

iature electrical

crocodile clip as I s

old

er it

in

positio

n. I f

it all six bra

kes

to roug

hly

line u

p w

ith

th

e w

heels

first an

d then

work

around t

weak

ing

with

plie

rs or resolde

rin

g

until I a

m hap

py th

at the

y are po

sitioned

correctl

y w

ith

n

o risk

of to

uchin

g a w

he

el.

32m

m

56

58

57

0.9m

m w

ire

Cross shaf

t

PAGE 15