39

38

37

Copp

er r

od

pin

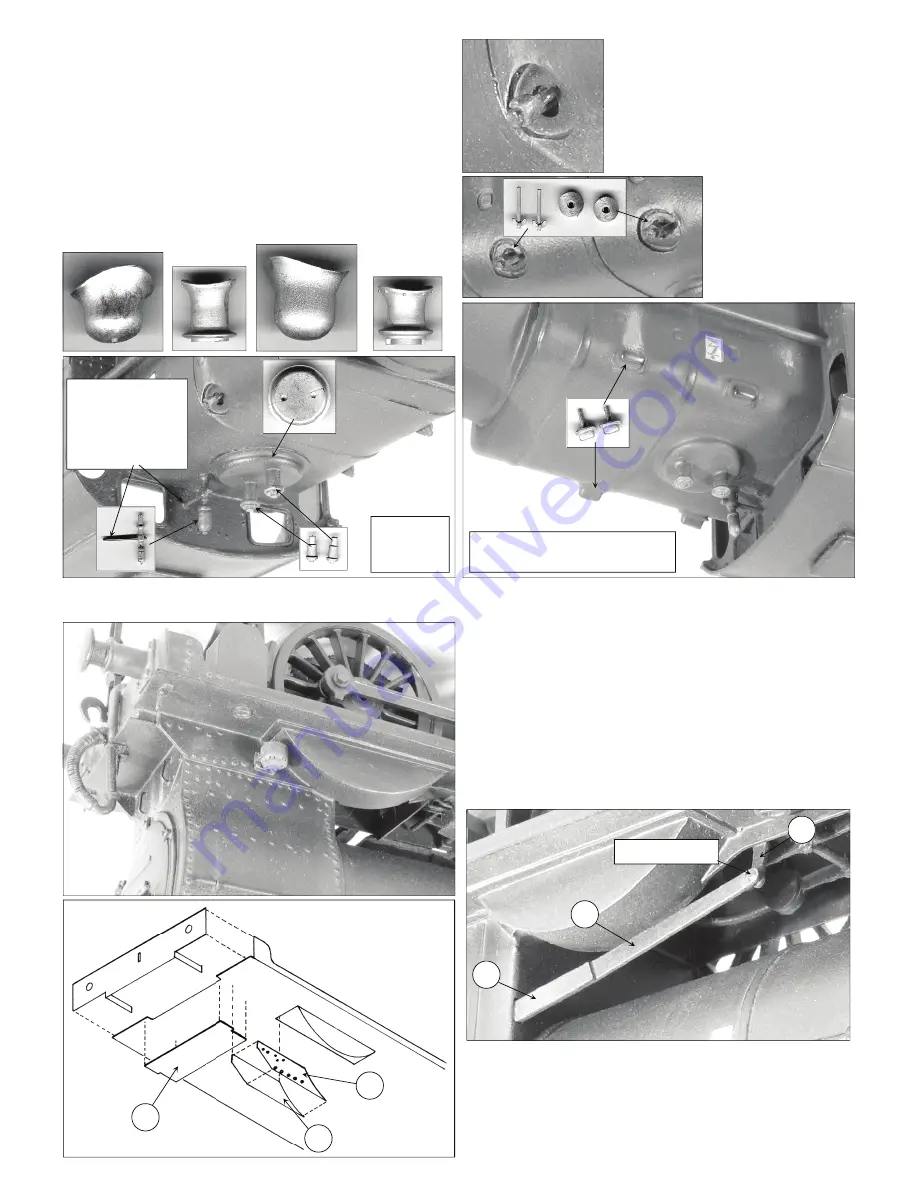

7.

Take

the re

versing

gear o

perating arm

(part 37

) a

nd

solder throu

gh the slo

t i

n th

e fo

otplate. Sold

er a

piece of

copper ro

d through

the

ho

le in th

e to

p to

form

a jo

int pin.

Take

the reversin

g reach rod (p

art 38)

and solde

r th

e cover

plate

(part

39) on

top

. Th

en f

it th

e reach

rod throug

h the slo

t

in th

e fire

box

fro

nt an

d slid

e the

othe

r en

d o

nto

the

pin in

the

operating a

rm

.

41

40

42

Ta

ke

the f

ron

t f

ram

es (parts 40

) and la

mina

te ont

o them

the

rivet detail overlays

(part

s 41

). So

lder th

em to

the f

ootpla

te

ma

kin

g sure tha

t th

ey ar

e tight up

to the

smo

ke b

ox sid

e a

nd

blend

in to

the spla

sher c

urve.

Ta

ke

the f

ron

t fo

otplate

sectio

n (part 42) an

d so

lder hard

against the

smo

ke

box

fro

nt b

etw

een

the fr

ames.

It

ma

y be

nec

ess

ary to

file

the

part

to

ach

iev

e a

good

fit.

PAGE 8

Mu

d Hole Do

ors

late

r ty

pe. Th

ese

seemed to be

fitted

to

mo

st locos in BR

days

but ch

eck

yo

ur

prototyp

e photos. I

have

pro

vid

ed sm

all

diam

eter etch

ed hole

s

fo

r fitting

the e

arl

y t

ype

co

ver so

open

these out

usin

g a tap

ered broach or

re

amer

to

4.5

mm

diam

ete

r a

nd

rem

ove

any b

urs

fro

m around

the

holes.

Fit the cast clam

p into the

roun

d bod

y an

d then m

ount in

to hole

s

fro

m th

e inside of the

fire

box.

FIREBOX MUD HOLE DOORS

Early t

ype

cover

Solde

r bras

s

whis

tle p

ipe

into

cab f

ront

to

provide m

axi

mu

m

strength

WHIS

TL

E

& SAFETY

VA

LVE

Chim

ney

Midla

nd T

ype

Dome

Tall

Chimney

LMS T

ype

Dom

e Short

A nu

mb

er o

f d

iffe

ren

t ch

imne

ys an

d do

me

s wer

e f

itte

d to

the 4F

class

over the y

ea

rs. I h

ave p

rov

ided

tw

o altern

atives

fo

r e

ach that cover the

m

ajo

rity of

the class b

ut

aga

in ch

eck

pho

tos

of y

our

ch

ose

n pr

otot

ype.

As

a rule of

th

umb

in

ea

rly

years m

ost of the

class w

ere f

itted w

ith the Midland t

ype,

with

or w

ithou

t ca

puchin, a

nd

tall

dom

e.

In late

r ye

ars the

ta

ller

LMS Stanie

r type

w

as f

itted

with

the

sho

rt dom

e. M

y sam

ple

mo

del is fitte

d w

ith tall ch

im

ney

and do

me

ju

st to b

e d

iff

erent.

PAGE 21