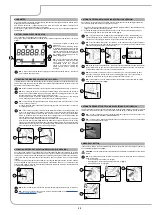

LIST OF ALARMS

LOCK ALARMS

The alarms listed in the table below can be reset only be switching the machine off. They can entail the

immediate stopping of the entire machine or a part of it.

MANUAL RESET ALARMS

The alarms listed in the table below can be reset manually using the user interface. They can entail the

immediate stopping of the entire machine or a part of it.

AUTOMATIC RESET ALARMS

The alarms listed in the table below can be reset automatically when the problem is solved. They can

entail the immediate stopping of the entire machine or a part of it.

ALARM

NUMBER

DESCRIPTION

LOCK

MANUAL

AUT

OMA

TIC

AL_1: General

Memory Error

X

AL_2: General

Issue with Key

X

AL_3: General

Undervoltage

X

AL_4: General

Overvoltage

X

AL_5: General

Batt. Connection

X

AL_6: General

Dashboard Communication

X

AL_7: General

FFM Communication

X

AL_8: General

Communication Internal 1

X

AL_9: General

Communication Internal 2

X

AL_10: General

Enter Tag

X

AL_11: General

Invalid Tag

X

AL_12: General

Update in progress…

X

AL_13: General

Switch off

X

AL_14: General

Full recovery

X

AL_15: General

Brake fluid Reserve

X

AL_41: Function

Overtemperature

X

AL_42: Function

Power Board Damaged

X

AL_43: Function

Main Fuse Faulty

X

AL_44: Function

Main Contactor Faulty

X

AL_45: Function

Main Contactor Faulty- CC

X

AL_46: Function

Overcurrent Outputs Brushes 1-2-3

X

AL_47: Function

Overcurrent Outputs vacuum Cleaner 1-2

X

AL_48: Function

Overcurrent Outputs Water Pumps

X

AL_49: Function

Amperometric Output Brushes 1

X

AL_50: Function

Amperometric Output Brushes 2

X

AL_51: Function

Amperometric Output Brushes 3

X

AL_52: Function

Amperometric Output Vacuum Cleaner 1

X

AL_53: Function

Amperometric Output Vacuum Cleaner 2

X

AL_60: Function

Timeout Actuator 1

X

AL_61: Function

Amperometric Actuator 1

X

AL_62: Function

Overcurrent Actuator 1

X

AL_63: Function

Limit Switch Incorrect Actuator 1

X

AL_64: Function

Timeout Actuator 2

X

AL_65: Function

Amperometric Actuator 2

X

AL_66: Function

Overcurrent Actuator 2

X

AL_67: Function

Limit Switch Incorrect Actuator 2

X

AL_68: Function

Timeout Actuator 3

X

AL_69: Function

Amperometric Actuator 3

X

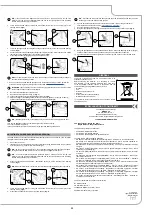

ALARM

NUMBER

DESCRIPTION

LOCK

MANUAL

AUT

OMA

TIC

AL_70: Traction

Overcurrent Actuator 3

X

AL_71: Traction

Limit Switch Incorrect Actuator 3

X

AL_80: Traction

Overtemperature

X

AL_81: Traction

Power Board Damaged

X

AL_82: Traction

Main Fuse Faulty

X

AL_83: Traction

Main Contactor Faulty

X

AL_84: Traction

Main Contactor Faulty- CC

X

AL_85: Traction

Overcurrent Traction Output

X

AL_86: Traction

Amperometric Output Traction

X

AL_87: Traction

Motor Reading

X

AL_88: Traction

Electric Brake Issue

X

AL_89: Traction

Pedal Faulty

X

AL_90: Traction

Pedal Pressed

X

AL_91: Traction

Encoder Fault

X

34