N.B.

: you are advised to only lift and move the batteries with lifting and transportation means

suitable for the specific weight and size

CAUTION

: the lifting hooks must not damage the blocks, connectors or cables.

12. Place the batteries or battery box in the dedicated compartment under the operator's seat.

CONNECTING BATTERIES TO THE MACHINE

The batteries should be connected so as to obtain a total voltage of 36V.

ATTENTION

: it is recommended that all installation and maintenance operations be carried out

by expert personnel, trained at the specialised assistance centre.

CAUTION

: to prevent an accidental short circuit use insulated tools to connect the batteries, and

do not place or drop metal objects on the battery. Remove rings, watches and any clothing with

metal parts that may come into contact with the battery terminals.

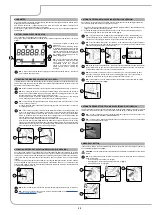

The stages for connecting the batteries to the machine's

electrical system are as follows:

1. Using the supplied jumper cable (1), connect the

batteries to the "+" and "-" poles in sequence.

2. Connect the battery connector cable (2) to the

“+” and “-“ poles to obtain a voltage of 36V at the

terminals.

3. Connect the electric system connector (3) to the

battery connector (2).

3

2

1

RECHARGING THE BATTERIES

The batteries must be charged prior to first use, and whenever they no longer provide sufficient power.

N.B.

: Carefully read the Use and Maintenance Manual for the batteries you wish to use before

charging.

1. Bring the appliance to the zone where the batteries are charged.

2. Make sure the machine has been secured (see the section titled “

”).

ATTENTION:

park the appliance in an enclosed place, on a flat surface; near the appliance there

must be no objects that could either damage it, or be damaged through contact with it.

ATTENTION:

the room used to recharge the batteries must be adequately ventilated to prevent

the accumulation of gases that leak from batteries.

3.

Get off the machine.

CAUTION

: when getting down from the machine, do not place your foot on the scrubbing brush

head or side brush head brush.

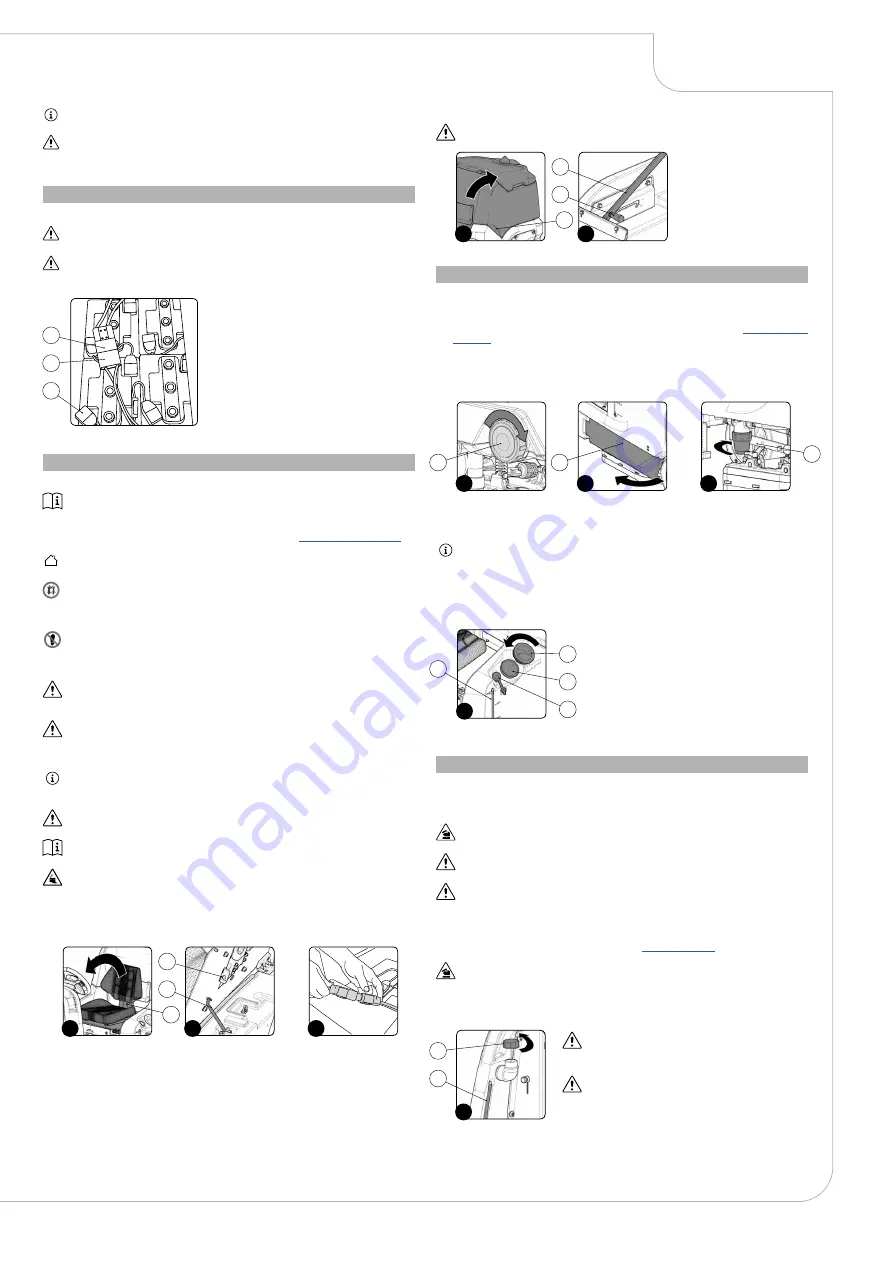

4. Grip the back of the seat (1) and turn the seat support plate to its maintenance position (

Fig.1

).

ATTENTION

: to prevent the seat from rotating, insert the retainer (2) into the slot (3) (

Fig.2

).

5. Disconnect the battery connector from the machine's main system connector (

Fig.3

).

ATTENTION

: the following operations must be carried out by qualified personnel. An incorrect

connection of the connector may cause a malfunction of the device.

6. Connect the external battery charger cable to the battery connector.

N.B.

: the coupling connector of the battery charger is consigned inside the bag containing this

instruction booklet, and must be assembled on the cables of the battery charger as indicated in

the instructions.

ATTENTION

: Before connecting the batteries to the battery charger, make sure it is suitable for

the batteries you want to use.

N.B.

: carefully read the use and maintenance instructions of the battery charger that is used for

charging.

CAUTION

: keep the recovery tank open for the duration of the battery recharging cycle to allow

gas fumes to escape.

7. Once the recharge cycle has been completed, disconnect the battery charger's cable from the

battery connector.

8. Connect the electrical system connector to the battery connector (

Fig. 3

).

9. Grip the back of the seat (1) and turn the seat support plate to the working position.

1

2

3

1

3

2

10. Grip the handle (4) and lower the recovery tank to the maintenance position (

Fig.4

).

ATTENTION

: to prevent the recovery tank from rotating, grip the handle (5) on the safety stop

lever (6) and position the lever in the stop slot (

Fig.5

).

4

5

4

6

5

FILLING THE SOLUTION TANK

Before filling the solution tank, carry out the following steps:

1.

Take the machine to the usual place for filling the solution tank.

2. Perform the procedure for securing the machine ( see the section titled “

3. Check to make sure that the solution tank drainage cap (1) is closed. If this is not the case, close

it (

Fig.1

).

4. Move to the left side of the machine and open the left side casing (2) (

Fig.2

).

5.

Check to make sure that the water system's filter cap (3), located on the rear left side of the

machine, is closed, and close it if necessary (

Fig.3

).

The solution tank can be filled with water in two different ways:

•

Removing the cap (4) and filling the solution tank by means of a rubber hose or a bucket (

Fig.4

).

N.B.

: Check that the filter (5) under the filler cap (4) is positioned correctly; this is to prevent

impurities and dirt causing the appliance's water system to malfunction (

Fig.4)

.

•

Using the filler hose (6) (

Fig.4

). This supports the water hose on its own, but be sure to remove the

cap (4) to allow adequate air venting.

6. Fill with clean water, at a temperature not higher than 50°C and not lower than 10°C. The amount

inside the tank can be seen by means of the level tube (7) on the front left of the seat (

Fig.4

).

2

3

1

1

2

3

4

7

5

6

4

DETERGENT SOLUTION

For the versions without automatic detergent dosing system, after filling the solution tank with clean

water, add the liquid detergent to the tank in the concentration and manner indicated on the detergent

manufacturer's label. To prevent the formation of an excessive amount of foam that could damage the

vacuum motor, use the minimum percentage of detergent required.

CAUTION

: protective gloves should always be worn before handling detergents or acidic or

alkaline solutions, to avoid serious injury to the hands.

ATTENTION:

always use detergents whose manufacturer's label indicates their suitability for

scrubbing machines. Do not use acid or alkaline products or solvents without this indication.

ATTENTION

: always use low-foam detergent. To avoid the production of foam, put a minimum

quantity of anti-foam liquid in the recovery tank before starting to clean. Do not use pure acids.

For versions with automatic detergent dosing system, fill the solution tank with clean water and then

proceed as follows:

1. Make sure the machine is in a safe condition (read “

CAUTION

: protective gloves should always be worn before handling detergents or acidic or

alkaline solutions, to avoid serious injury to the hands.

2. Remove the cap (1) of the detergent canister (

Fig.1

).

3. Fill the canister with the desired detergent; it is possible to see the quantity ion the detergent

canister using the level tube (2) on the front left of the canister (

Fig. 1

).

ATTENTION

: always use detergents whose manufacturer's

label indicates their suitability for scrubbing machines. Do

not use acid or alkaline products or solvents without this indication.

ATTENTION:

the dosing system is suitable for frequent

maintenance cleaning. Acid or alkaline maintenance

detergent tank be used with pH values between 4 and 10

and that do not contain: oxidising agents, chlorine or bromine,

formaldehyde, mineral solvents. The detergents used must be suitable

for use with scrubbing machines. Wash the circuit with water after use

1

2

1

17