ADJUSTMENT INTERVENTIONS

ADJUSTING THE SQUEEGEE BODY'S RUBBER BLADES

The careful adjustment of the squeegee body rubber blades guarantees better cleaning of the floor.

To adjust the squeegee body blades, proceed as follows:

1. Sit on the driver’s seat.

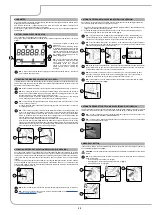

2. Insert the key (1) into the main switch on the control panel. Bring the main switch to its "I" position

by turning the key (1) a quarter turn clockwise (

Fig.1

).

N.B.

: As soon as the machine turns on, the control board will perform a diagnostics procedure,

during which the red LED indicator (2) on the control panel (

Fig.2

) will remain on.

N.B.

: If the control board's diagnostics procedure returns a positive outcome, the red LED

indicator (2) on the control panel (

Fig.2

) will turn off, and an acoustic signal will sound indicating

that the work operations may be initiated.

3. Lower the brush head body by turning the brush head control lever (3) on the rear part of the

steering column (

Fig.3

).

4. Lower the squeegee body by turning the squeegee control lever (4) on the rear part of the steering

column (

Fig.4

).

5. Check to make sure that the detergent solution tap is completely open. If this is not the case, adjust

the lever (5) on the left-hand side of the steering column (

Fig.5

).

6. Press the drive pedal (6) (

Fig.6

) to begin moving the machine.

2

3

1

1

2

3

ON

4

4

6

5

5

6

FILLING BRAKING SYSTEM OIL BASIN

If a braking system anomaly alarm is activated when you are working, quickly stop the machine and

check the oil level in the machine's brake system.

To check and top up the oil in the braking system, proceed as follows:

1. Take the machine to the maintenance area.

2. Make sure the machine has been secured (see the section titled “

”).

CAUTION

: these operations must be carried out using protective gloves to avoid any possible

contact with the edges or tips of metal objects.

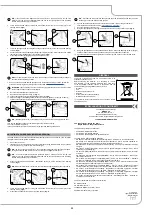

3.

Using the right equipment, not supplied with the machine, remove the screws (1) fixing the front

fairing to the steering column (

Fig.1

).

4. Using the handles (2) remove the fairing (3) from the machine and lay it on the ground (

Fig.2

).

5. Check the level of oil in the basin (4), if necessary adding fresh oil.

6.

To top up the braking system liquid basin, remove the cap-float (5) (

Fig.3

).

7. Put the brake liquid into the basin, being careful not to add too much.

N.B.

: for the machine's braking system use dot-4 brake fluids.

CAUTION

: to prevent serious injuries carefully read the product's safety sheet.

N.B.

: the place designated for this operation must comply with current environmental protection

regulations.

2

3

1

1

2

3

4

5

N.B.

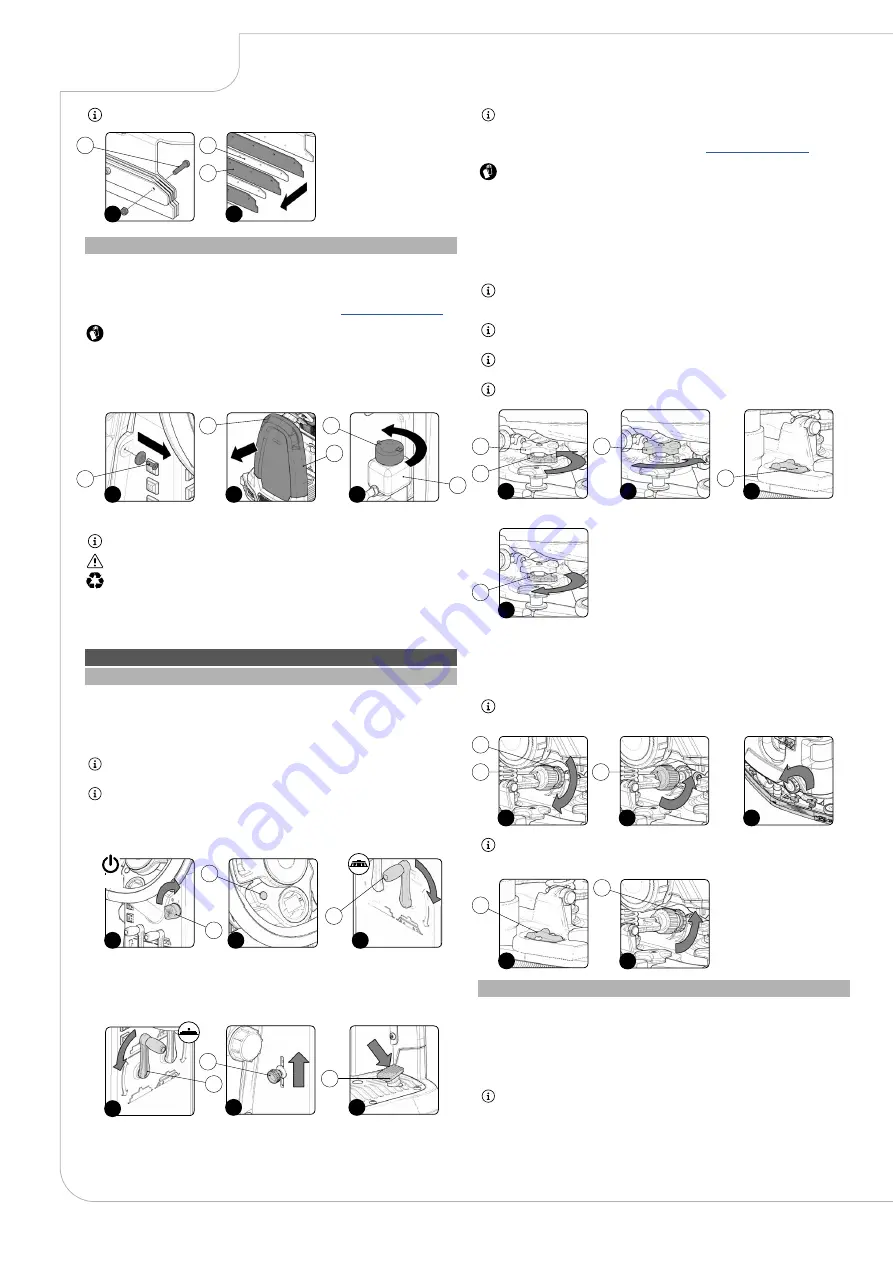

: when adjusting the side squeegee remember to leave about 10 mm of the threaded part

beyond the self-locking flanged nut (4) (

Fig.4

).

8

7

6

8

7

N.B.

: Once the drive pedal is pressed, the brush head body and the squeegee body will begin to

descend into their working positions.

7. As soon as the brush head and the squeegee have reached their working positions, perform the

procedure for securing the machine (see the section titled “

ATTENTION

: these operations must be carried out using protective gloves to avoid any possible

contact with the edges or tips of metal objects.

8. Stand at the back of the machine.

Adjusting the height of the squeegee body:

9. Release the stopper lever (1) for the squeegee's height adjustment knob (2) (

Fig.1

).

10.

Adjust the height of the rubber blade in relation to the floor by loosening or tightening the knobs

(2) (

Fig.2

).

N.B.

: Figure 2 indicates the direction of rotation for decreasing the distance between the

squeegee support and the floor. This distance can be increased by turning it in the opposite

direction.

N.B.

: By decreasing the distance between the squeegee support and the floor, the rubber blades

present in the squeegee's body move closer to the floor.

N.B.

: the right-hand and left-hand knobs must be rotated the same number of times, so that the

squeegee is parallel to the floor when it is working.

N.B.

: Check the adjustment is correct by looking at the horizontal bubble gauge (3) on the

squeegee body (

Fig.3

).

11. Once the adjustment has been completed, tighten the stopper lever (4) (

Fig.4

).

Adjusting the tilt of the squeegee body:

12. Loosen the stopper knob (1) of the squeegee's tilt adjustment (2) (

Fig.2

).

13.

Adjust the inclination of the squeegee body rubber blades with respect to the floor, tighten or

loosen the knob (2) (

Fig.2

), until the squeegee body rubber blades are bent towards the outside

evenly along the entire length by about 30° with respect to the floor.

N.B.

: Figure 2 shows the direction of rotation for tilting the squeegee towards the rear of the

machine (

Fig.3

). Turn it in the opposite direction to rotate the squeegee towards the front of the

machine.

N.B.

: Check the adjustment is correct by looking at the horizontal bubble gauge (3) on the

squeegee body (

Fig.4

).

14. Once the adjustment has been completed, tighten the stopper knob (1) (

Fig.5

).

2

3

1

1

2

2

3

4

4

2

3

1

2

2

1

5

4

1

3

ADJUSTING BRUSH HEAD BODY SIDE SPLASHGUARDS

If the side splash guards of the brush head body are not positioned correctly they cannot do their work

properly, namely convey the dirty detergent solution towards the squeegee, therefore the height of the

splash guard needs to be adjusted.

This operation can be done with the brush head body in the work position, proceeding as follows:

1. Sit on the driver’s seat.

2. Insert the key (1) into the main switch on the control panel. Bring the main switch to its "I" position

by turning the key (1) a quarter turn clockwise (

Fig.1

).

N.B.

: As soon as the machine turns on, the control board will perform a diagnostics procedure,

during which the red LED indicator (2) on the control panel (

Fig.2

) will remain on.

32