Summary of Contents for 277RFS-3

Page 1: ...OP RAT ON INSTRUCT ON PARTS l ST FOR ...

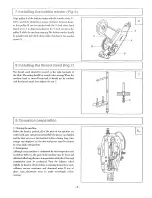

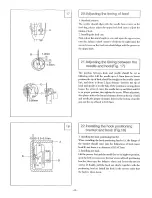

Page 3: ...o E 10 I STRUCTIO ...

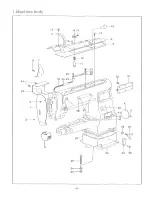

Page 12: ...P T ...

Page 13: ...44 43 2 33 l 1 34 J 35 3 9 ...

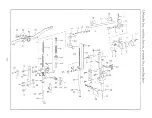

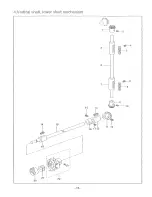

Page 19: ...3 6 1 7 14 1 I I I _________ L I _________ I _ r 21 v 20 22 ...

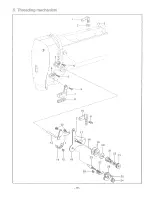

Page 23: ... echan s_m_l_ _____ Co Threading m 71 u 1 ___ QV I I fT I jill i jl I I J III 2 _ g 19 21 ...

Page 25: ...70 Accessories 8 1 3 11 15 18 19 13 22 26 9 I I I T rf 23 27 28 21 ...