© Constructor 2020

5

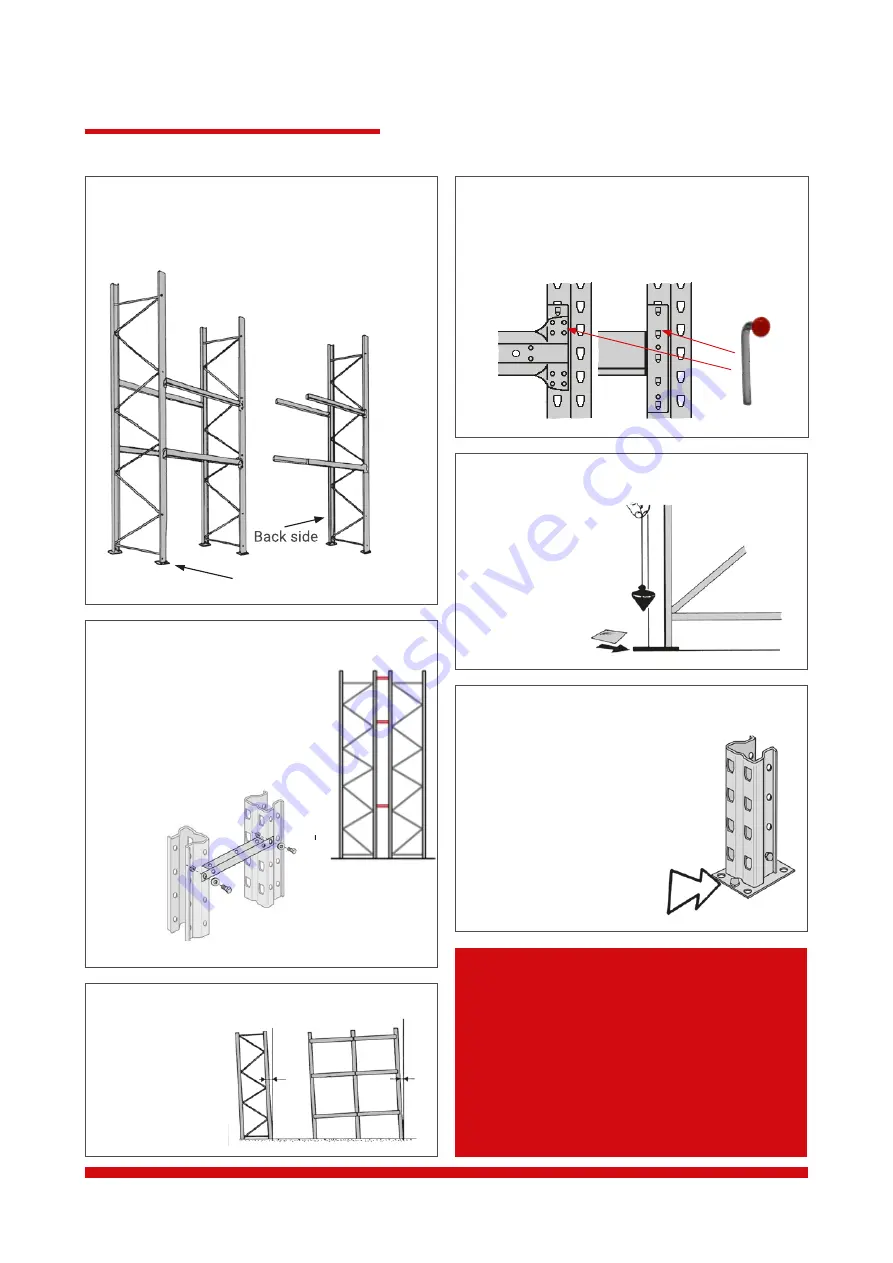

Upright installation

Installation of start / follow bay

Be careful to position the handling and back

side correctly.

Spacing - double racking

Spacers are placed maximum

100 mm from the attachment

points of the diagonal bracing.

The first is approx. 1300 mm

from floor and in top. Hereafter at

every 4th diagonal bracing.

Handling side

Bolt bracket,

nut M10 nyloc

Max 100

mm

+

Supporting beam

Place the supporting beam, and secure it

with the safety pin.

Control of plumb line

Level if

required.

Inclination

Direction

connected to

the plumb line -

max H/500 (2,0

mm/m)

Anchorage

All uprights must be anchored

to the floor. One expansion

bolt/concrete screw per foot.

Anchorage should be in the

middle slot.

If anchoring in other floors

other than concrete,

please contact Constructor

for guidance.

NOTE!

Prior to the pallet racking being anchored

in the floor, there is a risk of the rack

tilting. The risk is increased proportionally

to depth and height of upright.

If you have any questions, please contact

the manufacturer.