OPERATING & INSTALLATION INSTRUCTION 2-POST-LIFT

Description of the main board SGMX2

for EL-lifts

Overview:

The lift is equipped with an electronic control board.

The upper and lower limits can be adjusted to required circumstances.

The stored data can be adjusted to required circumstances.

The stored data is permanent and will not be lost when there is no power.

During the first installation of the lift, it is necessary to check the adjustment of the upper and lower

limits. If necessary, they have to be adjusted.

Required adjustments during installation:

Adjustment of lower and upper limits. Synchronisation of both carriages. Adjustment of the safety Stop when

lowering at a height of min. 200 mm above the ground.

Safety stop:

When lowering the lift, the carriages stop at the programmed point. After pushing the down button agains,

the carriages continue to the lower limit. You can hear the auditible warning noise during this operation.

Attention!

During programming the lift, the automatic limits do not work. –danger of collision in the upper and lower

limits-. Take care of approx. 10 mm overrun.

Initial installation:

Due to different local requirements and individual wishes, the different limits must be programmed.

Standard adjustments:

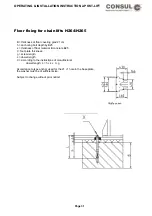

The lower limit:

Between the lowest point of the arm and the ground, there should be at least

10 mm of space.

The upper limit: Between the base plate and the lowest point of ther arm, there should be

A max. difference of 1900 mm.

Safety stop:

There should be a minimum of 200 mm between the lowest point of the arm and the

ground.

Preparation for the initial installation:

During the initial installation of the arms, or after repair, these should be conducted approx. 10 mm over the

lowest position as in the normal case. The lower position drive can be carefully followed with the lever

up/down in twice or indiviudal drive.

Notice:

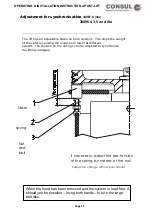

The potentiometers are protected against mechanical breakage by means of a mechanical

end stop. It is possible, that the lower limit cannot be reached by using the motor. In this

case, the potentiometer has to be dismounted and the carriage should be lwoered by

turning the pulley on top of the lift. When reaching the lower limit of the carriage, turn the

potentiometer clockwise until you reach the mechanical end stop. After that turn it back half

a turn.

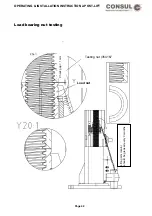

In the lower lifting carriage position the path transitter pinion when unlocked is turned clockwise (seen from

above) until it reaches the mechanical Stopp, then turned back half a turn. With light pressure it will then

return to the locked position and the M6 safety screw of the path transmitter mounting is again secured.

Make sure there is an undamaged spring wahser under the screw head.

Page 45

Summary of Contents for 2.25 EMC

Page 67: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Electric diagram H342 Page 67 ...

Page 68: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Electric diagram H325 Page 68 ...

Page 70: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Electric diagram with push button Page 70 ...

Page 71: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 71 ...

Page 72: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 72 ...

Page 73: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 73 ...

Page 74: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 74 ...

Page 75: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 75 ...

Page 76: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 76 ...

Page 77: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 77 ...

Page 78: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 78 ...

Page 79: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 79 ...

Page 80: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 80 ...