OPERATING & INSTALLATION INSTRUCTION 2-POST-LIFT

Emergency lowering II

Important:

While in the emergency lowering procedure. The automatic end limits are switched off. It is possible to drive the lift into

the floor causing damage.

Notes:

The procedure described below for the emergency lowering of the lift may only be undertaken by authorised, trained

personnel. A second person should watch the procedure from outside the operating area to ensure the safety of the

operator and vehicle.

The emergency lowering procedure must be terminated immediately, if any danger should arise. Restarting the

emergency lowering procedure should begin again once the cause of the danger has been removed. It is only possible to

lower the lift once, making sure that the bad carrying parts do not touch the floor.

Operating the emergency lowering procedure:

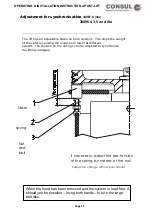

Emergency lowering using the motors can be necessary if the electronic controls fail. If other elements fail, then the lift

should be lowered manually (by turning the bolt on the large pulley).

The main switch must be on the „off“ position. The screws should be inserted into the two contactors and locked into

position (as shown in the diagram) to enable emergency lowering.

If the two sides are not synchronised then by locking only one contactor, the arms can be brought on the same level.

Extreme care must be taken and levelling should be done in small steps.

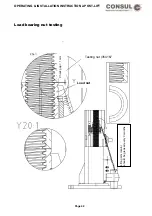

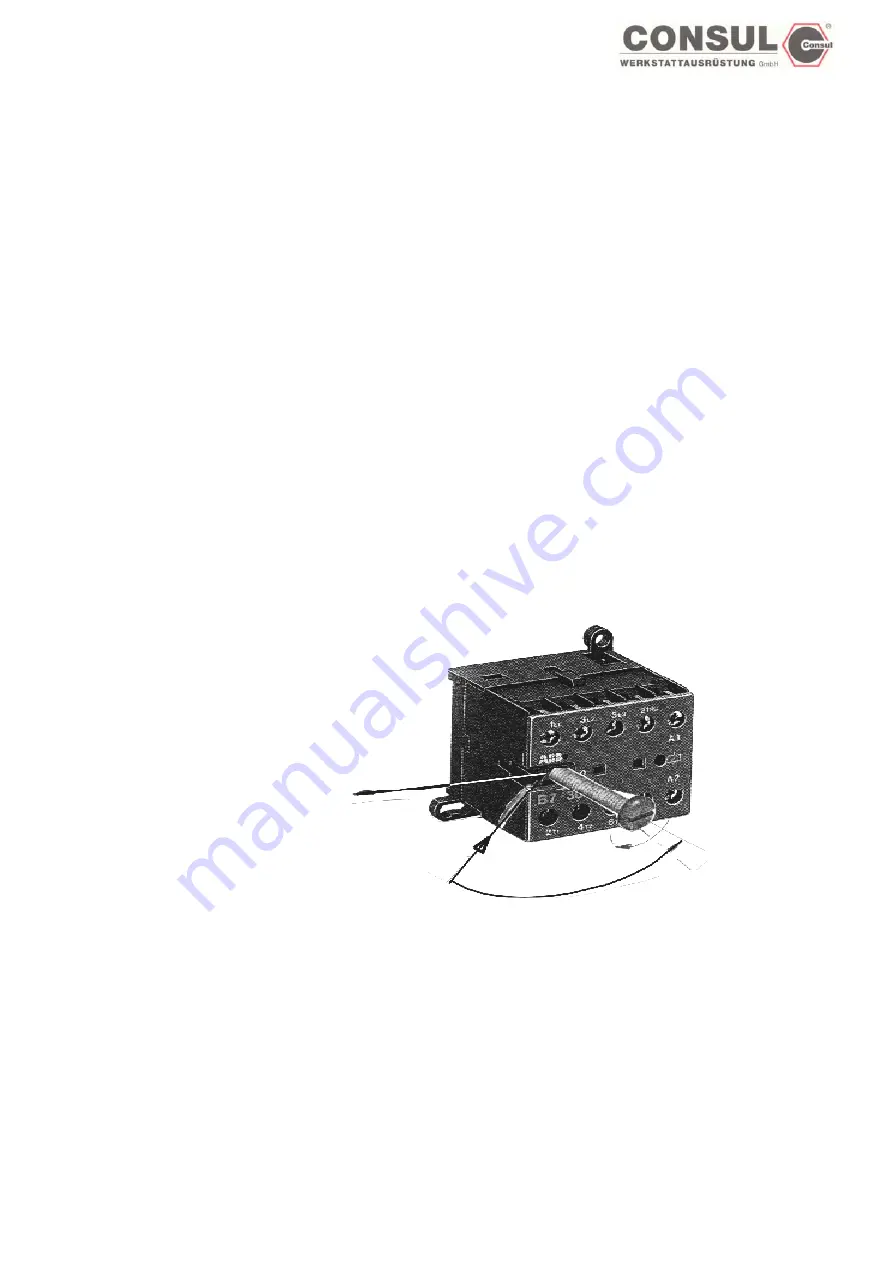

Locking the contactors

(the second contactor is

the Mirror image):

Direction for pushing the

operating bar

plastic screw

Insert the locking screw at an angle as shown in the sketch. Using the screw, press the locking bar slighly in the direction

of the arrow, then turn the srew clockwise, locks the locking bar. Set the main switch to 1. The emergency lowering

procedure can be carried out by loosely inserting the switch toggle after removing it from the lid.

Warning: No automatic end switching-off.

When the maximum necessary lower position of the load carrying equipment has ben reached, immediately

set the main switch to 0 and remove the locking immediately. Moving the unit upwards again with the locking

screw in position is not permitted. The lift must not be used again until all defects have been repaired by

authorised personnel

.

Page 51

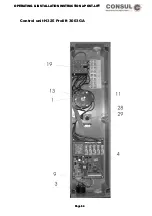

Summary of Contents for 2.25 EMC

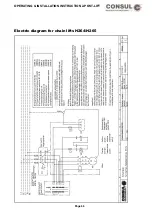

Page 67: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Electric diagram H342 Page 67 ...

Page 68: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Electric diagram H325 Page 68 ...

Page 70: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Electric diagram with push button Page 70 ...

Page 71: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 71 ...

Page 72: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 72 ...

Page 73: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 73 ...

Page 74: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 74 ...

Page 75: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 75 ...

Page 76: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 76 ...

Page 77: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 77 ...

Page 78: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 78 ...

Page 79: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 79 ...

Page 80: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 80 ...