OPERATING & INSTALLATION INSTRUCTION 2-POST-LIFT

Emergency lowering I

Important:

During movements in emergency operation, there are not

automatic end switch-offs. Further movements as far as the

mechanical end stops may result in damage.

Notes:

The emergency lowering process described below must only

be carried out by authorised and trained personnel. A second

person must stand outside the danger area to monitor the

safety of staff and materals in the lifting platforma area.

At the first indication of any danger, the movement must be

stopped immediately. No further movement must take place

until the source of the danger has been removed. The only

permitted function is a single downward movement –however,

ensure that the load support equipment does not touch the

floor.

Emergency lowering

If the eectronic control system fails, it may be necessary to

carry out emergency lowering using to motor. If other

elemeents fail, carry out emergency lowering by hand (by

turning the big belt disc).

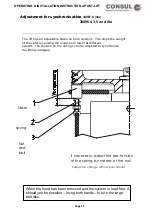

The main switch must be set to 0. As per the sketch, the

lowering contactors must be locked for a single emergency

lowering process by using the enclosed plastic screws.

If there is any uneveness in the lifting apparatus it may be

possible to overcome this by locking just one of the safety

devices, Be especially careful while carrying out all

movements, which should only take place for short intervals.

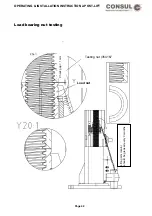

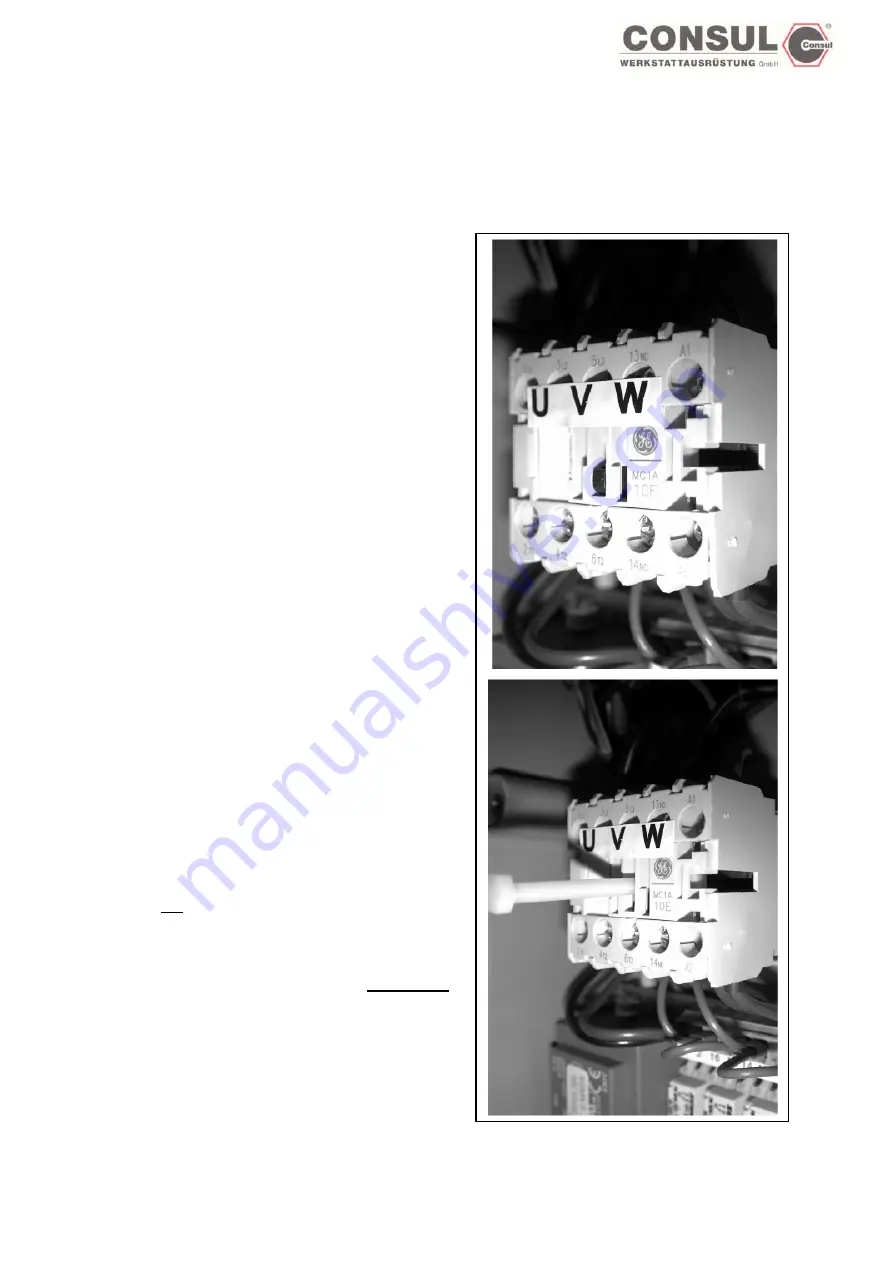

Locking main contactor K2 and K4:

Insert locking screw in accordance with the sketch. The screw

pushes the locking bar in the direction of the arrow and locks it.

Set the main switch briefly to 1 in order to control the correst

direction of movement of the carriage, then press the main

switch again to continue the downwards movement.

Warning:

No automatic resetting of the main switch, no

automatic end switching-off.

When the maximum necessary lower position of the load

carrying equipment has been reached, immediately set the

main switch to 0 and remove the locking screw immediately .

Moving the unit upwards again with the locking screw in

position is not permitted. The platform must not be used again

until all defects have been repaired by authorised personnel.

Page 52

Summary of Contents for 2.25 EMC

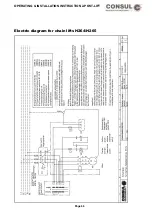

Page 67: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Electric diagram H342 Page 67 ...

Page 68: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Electric diagram H325 Page 68 ...

Page 70: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Electric diagram with push button Page 70 ...

Page 71: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 71 ...

Page 72: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 72 ...

Page 73: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 73 ...

Page 74: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 74 ...

Page 75: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 75 ...

Page 76: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 76 ...

Page 77: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 77 ...

Page 78: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 78 ...

Page 79: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 79 ...

Page 80: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 80 ...