OPERATING & INSTALLATION INSTRUCTION 2-POST-LIFT

Product description H264/H265/H342/H325

This lift consists basically of the main column and the slave column. In both columns are a chain drive,

connected lifting spindles and lifting carriage complete with lifting apparatus.

The drive turns the lifting spindle. On the spindles are nuts which are attached to the lifting carriage which,

according to the turning direction of the drive, moves up or down and thus performs the raising and lowering

pperation. The lifting carriage is borne on maintenance free roller bearings whithin the column. By shifting

the main drive switch or via a switch wire in the upper and lower positions. The main drive switch reverts

automatically to the stop position when released and stops the movement of the lift in each position of the

lifting apparatus.

The lift is also equipped with a variety of active and passive safety devices. An example of this would be the

safety device for broken load bearing nuts which transfers the load to a reserve safety nut in the event of a

worn thread. At the same time, a mechanical blocking system is engaged which prevents the continued

movement to the lowered position in the event of worn threads.

The swivel arm lock of lift type H264/H265 stops the load arms moving after travelling upward a short

distance from the lowered positon. This is to prevent the lifting apparatus slipping from the jacking points on

the vehicle being raised. Operating safety is paramount!

The swivel arm lock of lift H342 Consul 2.60 stops the load arms moving after travelling upward

approximately 25 mm from the lowered position. This is to prevent the lifting apparatus slipping from the

jacking points on the vehicle being raised. Be aware of the meshing of the gears!

The chain break switch controls the chain drive and switches off the power in the event of a broken chain,

thus preventing the load being raised from falling off due to misalignment. Regular operating checks!

The heat sensor in the drive motors stops the lift in the event of overheating and only allows the lift to restart

after a cooling down period.

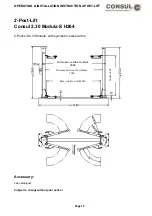

The 2-Post-Lift 265 (capacity: 3500 kg) is made with symmetrical swivel bearing arms as standard. Other

lifting apparatus available on request. All swinging arms for this lift have the same extended length and the

vehicle to be lifted is placed directly between the columns.

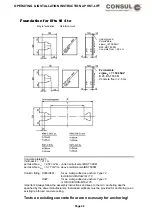

The 2-Post-Lift H342 (capacity: 6000 kg) is made with symmetrical swivel bearing arms as standard. Other

lifting apparatus available on request. All swinging arms for this lift have the same extended length and the

vehicle to be lifted is placed directly between the columns.

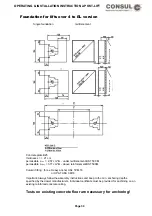

For the 2_post-Lift type: H264 (capacity: 3000 kg) you are offered symmetrical and asymmetrical loading

arms as well as a a quick take up version of the chassis. Where the unit has symmetrical loading arms, the

arms are all the same length and the vehicle to be lifted is placed in the middle of the 2 columns in the drive-

on direction.

With the asymmetrical design the loading arms are of different lengths. The short double swivel arms are in

the drive-on position forward and the long single swivel arms are in the drive-on position at the back.

The vehicle to be lifted is positioned so that the forward-most door hinges are close to the lift columns in

order to facilitate a wide opening of doors. It is desirable that the vehicle’s engine is towards the short swivel

arms (the centre of gravity of the vehicle as close as possible to the centre of lift!). All 4 lifting points are

positioned at the jacking points laid down by the vehicle manufacturer!

A more advanced design is the 2-Post-Lift with drive-on chassis. This lift has a fixed chassis as its lifting

apparatus. Only one axel of the vehicle to be lifted is to driven onto the chassis. The chassis grips onto the

door thresholds during the lift.

Page 25

Summary of Contents for 2.25 EMC

Page 67: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Electric diagram H342 Page 67 ...

Page 68: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Electric diagram H325 Page 68 ...

Page 70: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Electric diagram with push button Page 70 ...

Page 71: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 71 ...

Page 72: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 72 ...

Page 73: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 73 ...

Page 74: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 74 ...

Page 75: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 75 ...

Page 76: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 76 ...

Page 77: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 77 ...

Page 78: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 78 ...

Page 79: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 79 ...

Page 80: ...OPERATING INSTALLATION INSTRUCTION 2 POST LIFT Page 80 ...