20

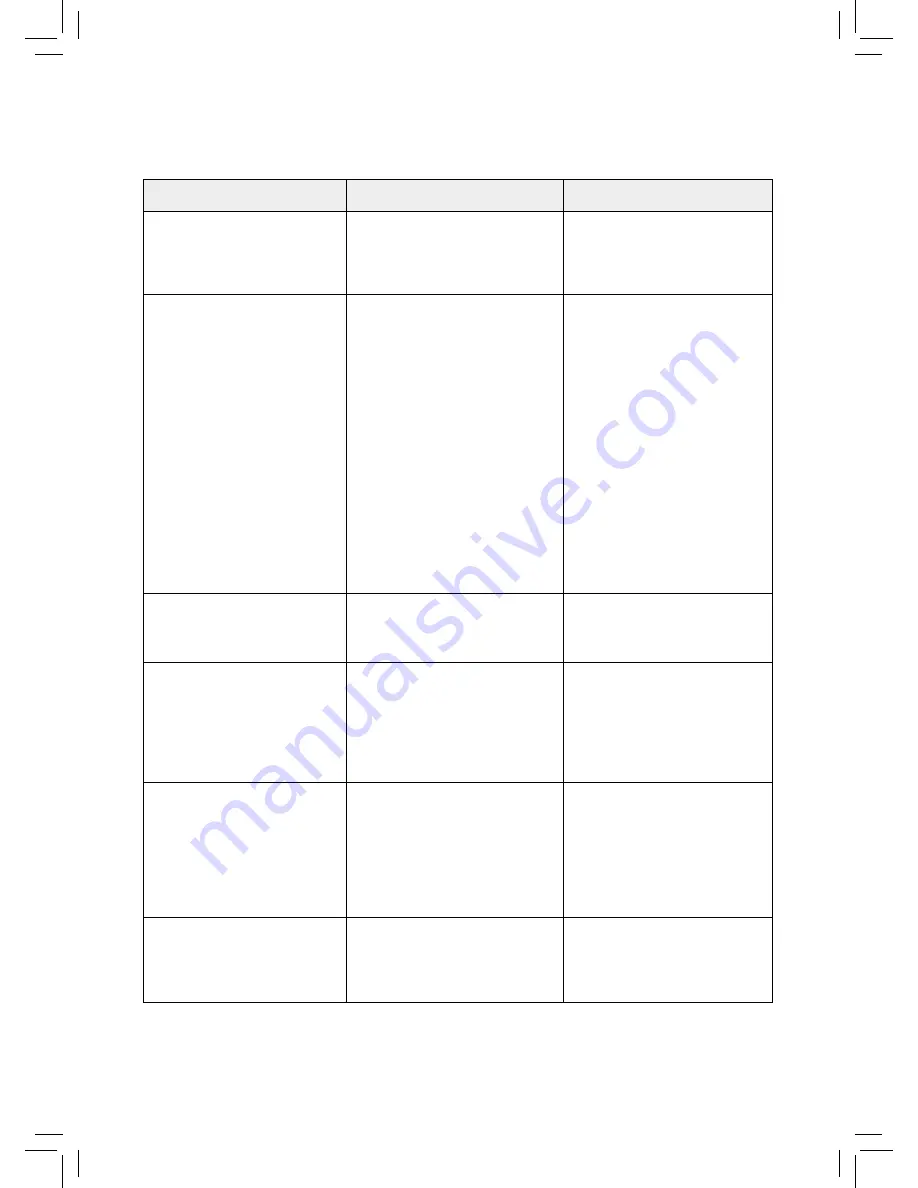

Troubleshooting

Symptom

Possible Fault

Action

I’ve adjusted the HF comp

and see no change.

1) T

he driver is working close

to maximum output so there is

not enough headroom for the

HF comp to make a difference.

1) Check loop characteristics.

If response OK at 1 amp, the

headroom is inadequate.

I start the driver and

immediately the status light

turns on.

I start the driver and the

test sequence starts, but the

status light turns on after it’s

completed.

I’ve connected the loop and

the driver doesn’t work, the

status light comes on.

My driver has been working

well for a couple weeks and

now the status light is on.

1)

Loop shorted or open, too

small or too large.

2)

Internal self-test failure.

1)

Check loop and

connections, try known good

loop.

2)

Check loop DC resistance

with an ohm meter:

0.33 ohms minimum.

The power light doesn’t

come on.

1) Mains power absent.

2) Internal failure.

1) Check mains power.

2) Seek assistance.

I can’t get my driver out of

adjustment mode.

1) Button presses not

coinciding.

2) Internal failure.

1) Press both buttons together

to exit mode.

2) As a last resort, cycle

power off/on. New settings

should have been saved.

Interference (buzzing/

whistling/hissing) is heard

through induction loop.

1) Bad input signals.

2) Internal failure.

1) Power off driver and

confirm that interference isn’t

from external origin.

2) Disconnect input signals.

If sound disappears, check

inputs.

My driver is very hot.

1) Large amount of mains hum

present on input.

2) Internal failure.

1) Check input signal source.

2) Incorrect driver being used.