IO-240 Series Engine Installation & Operation Manual

2-5

31 October 2011

Engine Description

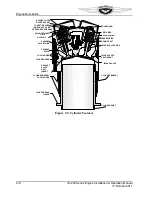

The flange type crankshaft has a propeller mount flange forged on the front end with six

tapped bushings pressed into holes spaced equally around the flange. Six bolts, screwed

into the shaft flange bushings, clamp the propeller between a loose front flange and the

shaft flange.

Figure 2-5. Crankshaft

2-2.2.2. Connecting Rods

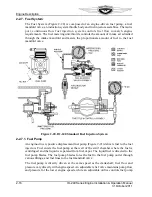

The connecting rods halves (Figure 2-6) are machined from a single forging of aircraft

quality steel and cut into two pieces, splitting the center of the larger opening of the

connecting rod assembly. The resulting pieces, called the rod and cap are fitted with a two

piece bearing and attach to the crankpin or rod journal with special bolts and nuts.

The portion of the rod between the rod and the crankpin and piston pin ends is called the

“I” beam. A split steel-backed bronze bushing is pressed into the piston pin end and

machined for a precision pin-to-bushing fit.

Figure 2-6. Connecting Rod

CRANKSHAFT

FLANGE

FRONT MAIN

JOURNAL

ROD JOURNAL

ROD JOURNAL

ROD JOURNAL

REAR MAIN

JOURNAL

MIDDLE MAIN

JOURNAL

OIL

PASSAGE

#1

#2

#3

#4

OIL

PASSAGE

CRANKSHAFT

FLANGE

FRONT MAIN

JOURNAL

ROD JOURNAL

ROD JOURNAL

ROD JOURNAL

REAR MAIN

JOURNAL

MIDDLE MAIN

JOURNAL

OIL

PASSAGE

CRANKSHAFT

FLANGE

FRONT MAIN

JOURNAL

ROD JOURNAL

ROD JOURNAL

ROD JOURNAL

REAR MAIN

JOURNAL

MIDDLE MAIN

JOURNAL

OIL

PASSAGE

#1

#2

#3

#4

OIL

PASSAGE

NOTE: Some older models use castellated nut with cotter pin

SPIRAL LOCK NUT

BRONZE BUSHING

CONNECTING ROD

CONNECTING ROD

CAP

ROD BOLT

SHELL

BEARING

Summary of Contents for IO-240-A

Page 145: ......

Page 146: ...www continentalmotors aero ...