2-6

IO-240 Series Engine Installation & Operation Manual

31 October 2011

Engine Description

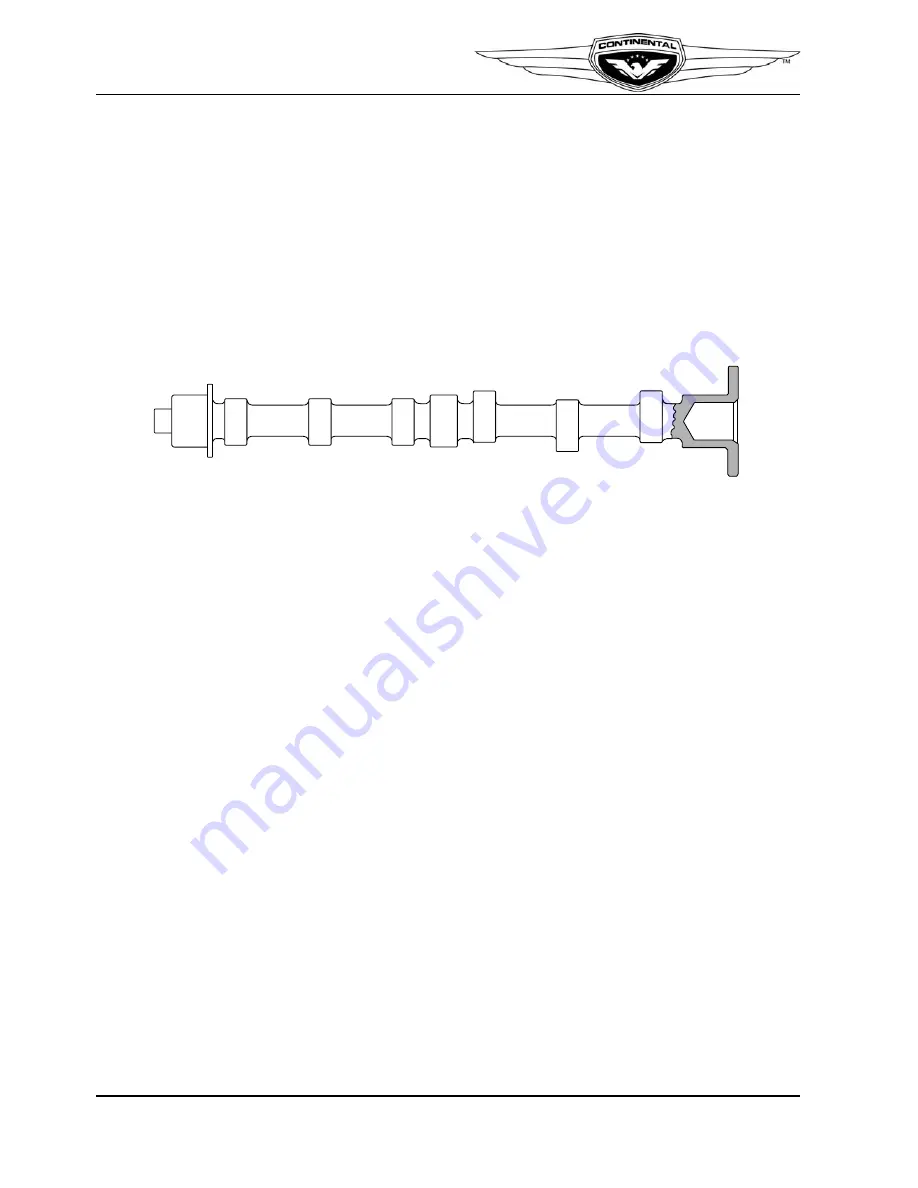

2-2.2.3. Camshaft

The camshaft forging is machined on three main journals, six cam lobes and the gear

mount flange at the rear of the camshaft (Figure 2-7). The lobes and journals are ground

and hardened. Camshaft main journals are supported in the crankcase by machined

bearing saddles. Hydraulic tappets move inward and outward in their bores, following the

eccentric shape of the cam lobes. Four unequally spaced bolts secure the gear to the

camshaft and ensure proper positioning, locating the gears' timing mark in relation to the

cam lobes. The camshaft gear has internal teeth to drive the alternator. A front-mounted

bevel gear drives the accessory drive bevel gear and fuel pump through a common shaft.

Figure 2-7. Camshaft

2-2.3. Accessory Case

The accessory case (Figure 2-8) aluminum alloy casting is attached to the rear of the

engine crankcase, aligned with crankcase dowels. The accessory case is secured to the

crankcase by crankcase studs and various attaching hardware. Accessory mount pads on

the rear surface are machined in one plane parallel to the machined parting flange which

surrounds the front side of the casting. Mounting pads for the magnetos, alternator cover,

starter, tachometer drive, oil filter adapter, oil pressure relief valve and an oil suction

screen boss are provided. The accessory case casting has two holes above and three studs

to attach the starter. A mounting pad is provided for a permanent oil screen housing. In

lieu of the oil screen housing, an oil filter adapter, with a screw-on type oil filter is also

available.

The oil pump housing is machined into the internal portion of the accessory case. A

machined, threaded boss is located on the lower right side of the accessory case for

installation of a non-adjustable oil pressure relief valve. Oil pump gear chambers are

machined in the interior of the accessory case. The oil pump drive gear shaft hole is

machined in-line with the camshaft and the driven gear shaft hole is directly above it.

A semicircular opening at the accessory case bottom is a machined threaded hole to

accommodate installation of the oil suction tube. Passages cast into the accessory case

allow oil to flow from the oil suction tube to the oil pump gears, pressure relief valve, and

main oil gallery. The tachometer drive shaft is the slotted end of the oil pump driven gear

shaft.

FRONT

REAR

#4 EXH

#3 EXH

#2 EXH

#1 EXH

#3 & 4

INTAKE

#1 & 2

INTAKE

M/J

C/L

C/L

C/L

C/L

C/L

C/L

M/J

M/J

C/L - CAM LOBE

M/J - MAIN JOURNAL

Summary of Contents for IO-240-A

Page 145: ......

Page 146: ...www continentalmotors aero ...