IO-240 Series Engine Installation & Operation Manual

2-7

31 October 2011

Engine Description

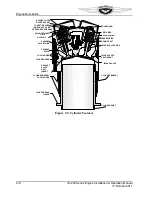

Figure 2-8. Accessory Case Features

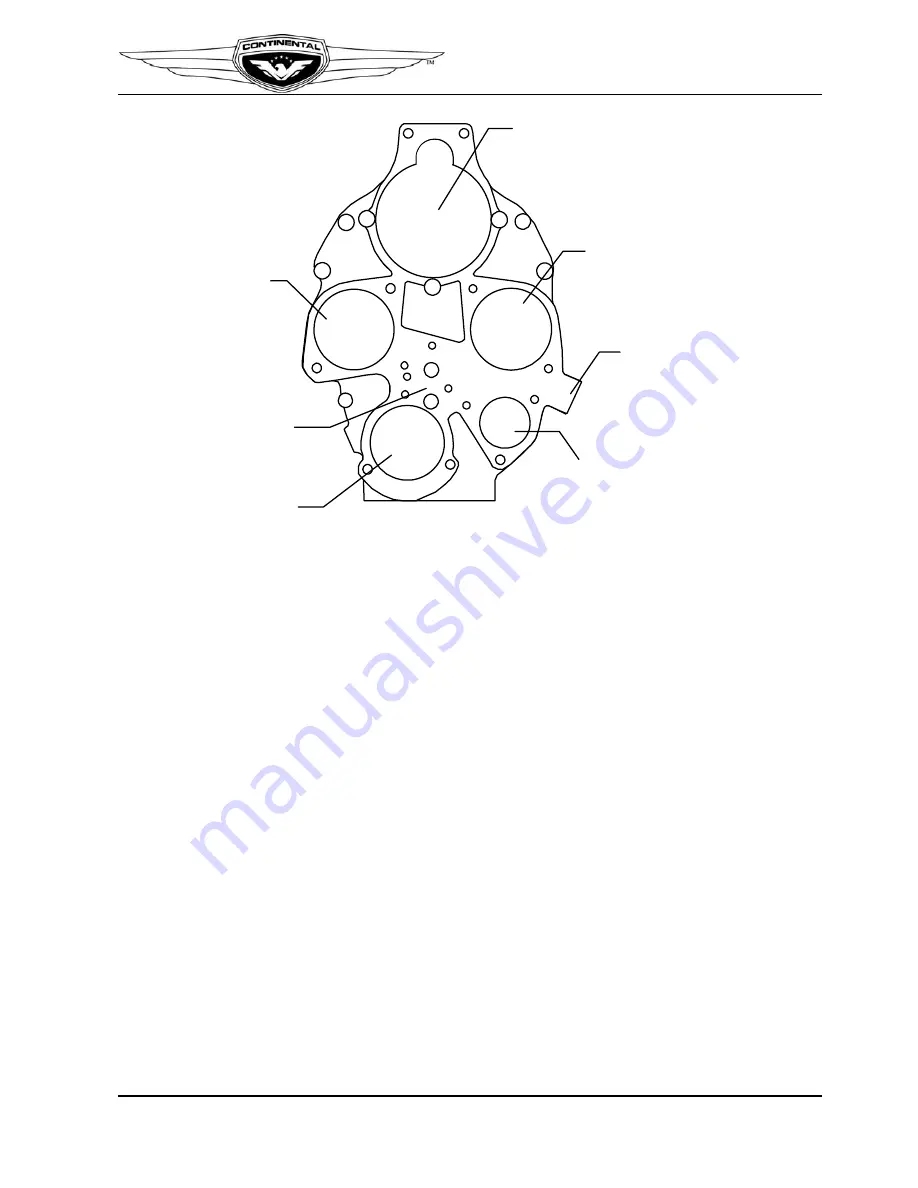

2-2.4. Cylinders

The IO-240 engine have four, horizontally-opposed, air cooled cylinders, two on the left

side and two on the right side of the engine. The cylinders, pistons and valve drive train

provide the momentum to sustain crankshaft movement. Aviation fuel and air are drawn

into a cylinder during the intake stroke, compressed by the piston during the compression

stroke and then ignited by a high intensity spark from each spark plug (two per cylinder).

As the mixture is ignited, the expanding gases force the piston to move inward toward the

crankshaft during the power stroke.

The head and barrel assembly (Figure 2-9) consists of externally finned aluminum alloy

head casting and a steel, nitrided cylinder barrel for wear resistance. Helical coil thread

inserts are installed in upper and lower spark plugs holes. A rotocoil assembly retains two

concentric springs surrounding the exhaust valve and is locked to the stem by tapered,

semi-circular keys which engage grooves around the valve stems. An outer retainer holds

two concentric springs which surround the intake valve and is locked to the stem by

tapered, semi-circular keys which engage grooves on the stem.

IO-240 Series engines use a cross flow cylinder head design. The intake ports are located

on top of the cylinder head while the exhaust ports are located below. There are separate

intake and exhaust valve rocker covers made from zinc-plated stamped sheet steel. This

cylinder design is used in conjunction with a Balanced Induction System mounted above

the engine.

STARTER MOUNTING

PAD

MAGNETO MOUNTING

PAD

TACH DRIVE

MOUNTING

PAD

ALTERNATOR

MOUNTING

PAD

OIL SCREEN

HOUSING

MOUNTING

PAD

OIL PRESSURE

RELIEF VALVE

HOUSING

MAGNETO

MOUNTING

PAD

Summary of Contents for IO-240-A

Page 145: ......

Page 146: ...www continentalmotors aero ...