IO-240 Series Engine Installation & Operation Manual

2-9

31 October 2011

Engine Description

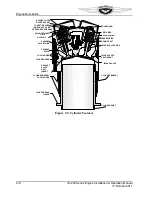

2-2.4.1. Pistons

Pistons (Figure 2-10) are aluminum alloy castings with a steel insert cast into the top ring

groove. The skirts are solid and have cylindrical relief cuts at the bottom. Pistons have

three ring grooves above the piston pin bore and one ring groove below. Compression

rings are installed in the top and second grooves. The groove below the piston pin bore

contains an oil scraper. A center grooved and slotted oil control ring is installed in the third

groove which has six oil drain holes to the interior. Weight differences are limited to ½

ounce between opposing cylinders bays. Piston pins are full floating with permanently

pressed-in aluminum end plugs.

Figure 2-10. Piston Features

2-2.4.2. Hydraulic Valve Tappets

The hydraulic valve tappet (lifter) provides an interface between the camshaft lobe and the

remaining valve train. Lifters ride on the eccentric cam lobes, opening and closing the

intake and exhaust valves mechanically via push rod tubes and rocker arms, converting the

cam lobe profile into a linear movement for intake and exhaust valves actuation. The

hydraulic mechanism inside the hydraulic mechanism maintains zero clearance between

the valve and actuating components.

PISTON PIN

MANGANESE PHOSPHATE COATING

GRAPHITE COATED SKIRT

1

ST

COMPRESSION

RING

2

ND

COMPRESSION

RING

OIL CONTROL

RING

OIL SCRAPER

RING

Summary of Contents for IO-240-A

Page 145: ......

Page 146: ...www continentalmotors aero ...