Non-Overhaul Removal and Replacement

Teledyne Continental Motors, Inc.

TM

10-46

IOF-240 Series Engine Maintenance Manual

Change 1

31 August 2007

10-10.2. EGT Sensor and Lead Wire Replacement

Equipment Required:

•

Crimp tool

•

EGT Sensor/Wire Splice Kit

•

Utility or razor knife

•

Scissors

•

A variable intensity heat gun with a small tip

Prerequisites:

Before proceeding, review Sections 10-1, “Parts Replacement” and 10-10, “Engine Low

Voltage Harness Lead Wire Repair and Sensor Replacement.”

Procedure

1.

Turn the Aircraft Master Power Switch and FADEC Enable Switches to the OFF

position and disconnect engine electrical power.

CAUTION: Failure to use the correct splice kit for sensors or lead

wires will result in abnormal engine operation and may cause

engine damage.

2.

Obtain the appropriate EGT Sensor/Wire Splice kit from TCM. The EGT splice kit

will not work for non-EGT sensors and the non-EGT splice kit will work for EGT

sensor wiring.

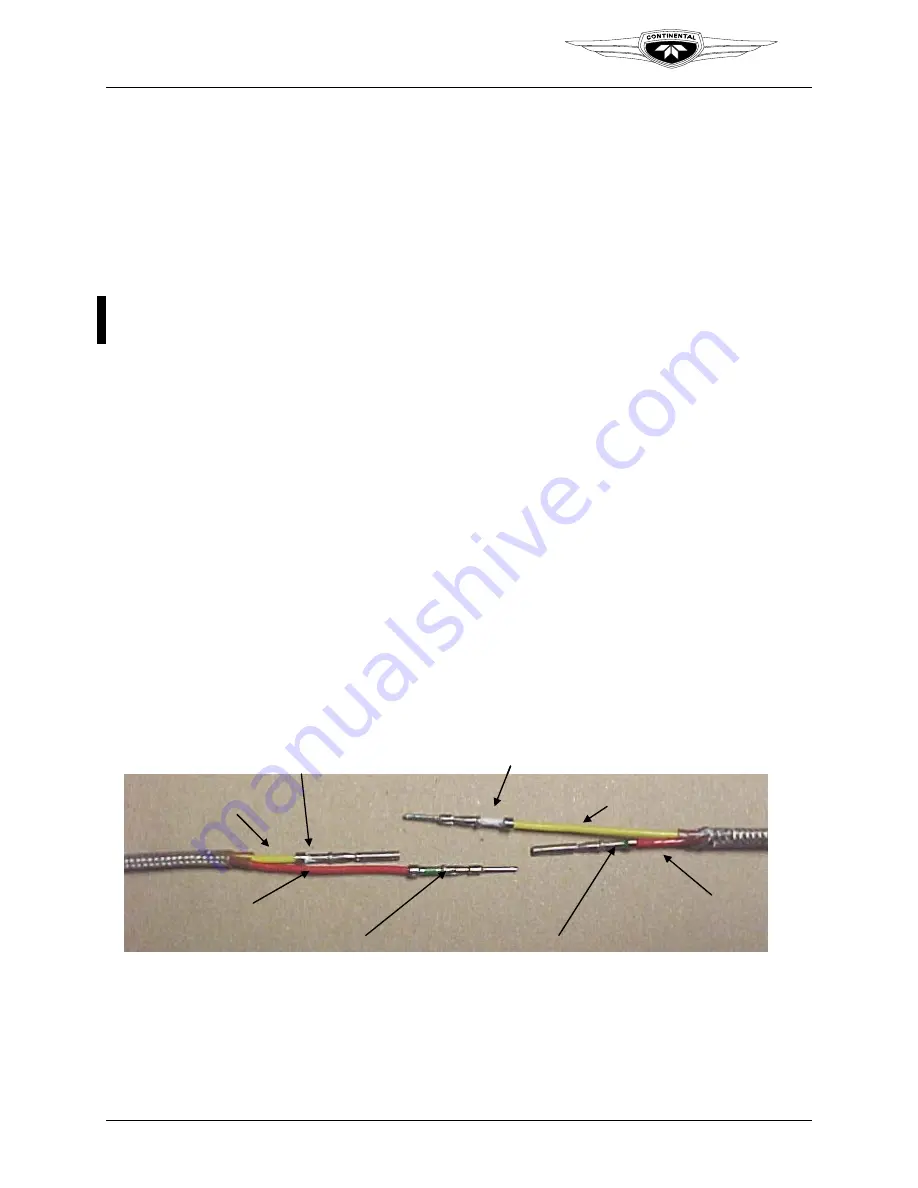

NOTE: Refer to Figure 10-25. The EGT wires are alumel (red) and

chromel (yellow). To maintain signal integrity, all segments of the

wire must be the same material. The EGT splice kit contains an

alumel (green band) pin and socket and a chromel (white) pin and

socket. Splices must be installed as directed for proper system

operation after repairs.

Yellow wire

Yellow wire

Red wire

Red wire

White pin

White socket

Green socket

Green pin

Yellow wire

Yellow wire

Red wire

Red wire

White pin

White socket

Green socket

Green pin

Figure 10-25.

EGT wire repair pins mated to wires

3.

Cut and remove all cable ties supporting the affected sensor or damaged wire section.

4.

Remove the faulty sensor or damaged wires.

5.

Cut the leads to be replaced two inches longer than the replacement leads, yielding a

four inch overlap.