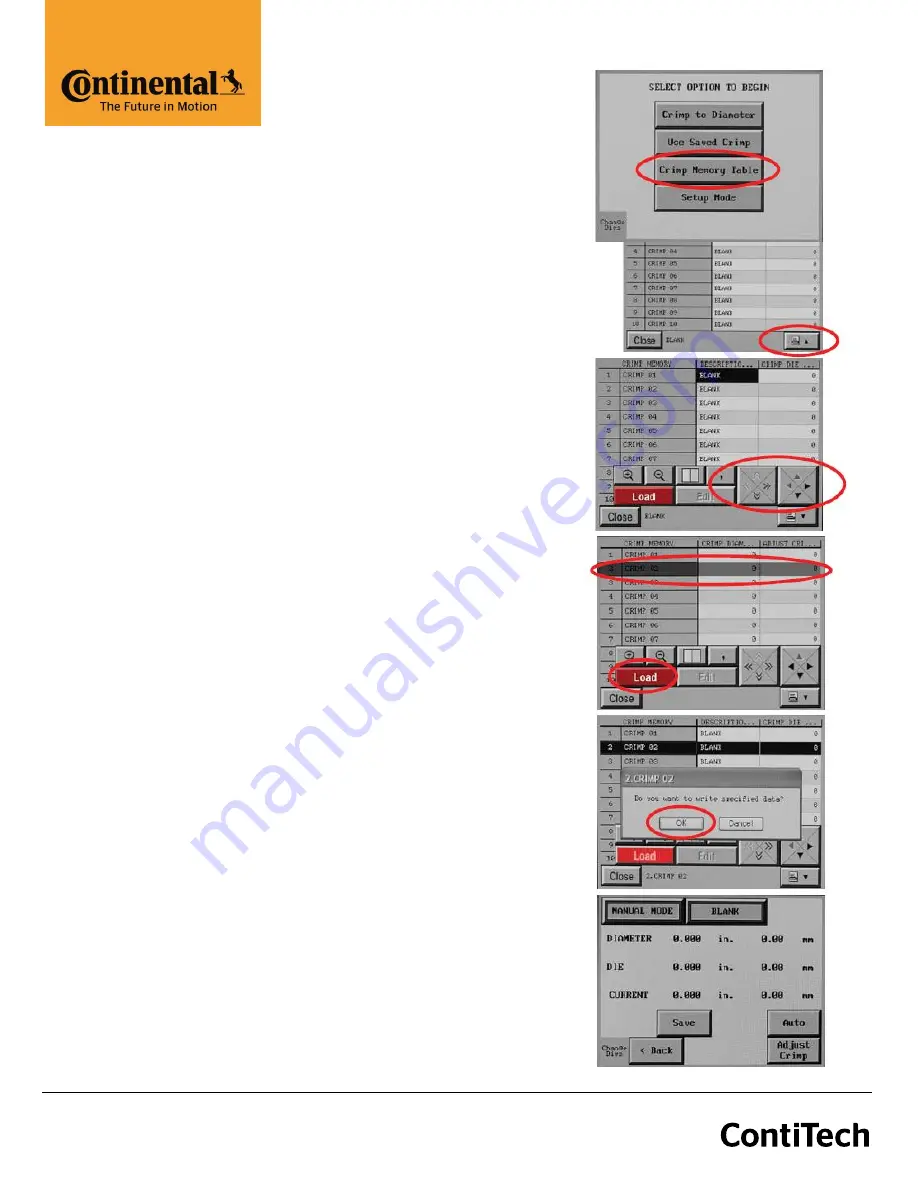

ACT™ Additional Features

Pre-Loaded Crimp Specifications

In addition to the ability to store up to 50 user entered

dies and 100 user entered crimp settings, the ACTTM

Controller has the capability of accepting pre loaded

manufacturer’s crimp specifications. PC440 does not

maintain these specifications as they are proprietary to

the individual hose and fitting manufacturer. If, however,

your ACTTM Controller was pre loaded with a

manufacturer’s crimp specifications or if they are available

to you, they are accessed in the following manner:

•

Press the Crimp Memory Table Button.

•

Press the access button to bring up the stored crimp

specifications.

•

Scroll through the crimp specifications to select the

correct one. The right hand rocker button moves

through the crimp specs one line at a time and the

left hand rocker button moves one screen at a time.

•

When the correct crimp specification is selected,

press the highlighted selection and then the Load

button and select OK to write the data to the ACTTM

Controller.

•

This will bring up the familiar crimp screen and the

crimper can then be operated in the normal manner.

703 S. Cleveland Massillon Road, Fairlawn, OH 44333 I 800.234.4632 I www.contitech.us