Troubleshooting

Teledyne Continental Motors, Inc.

TM

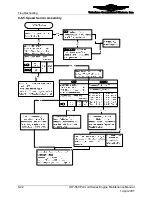

8-13.

Cabin Harness Functional Check

The functional check of the cabin harness consists of several procedures and must be

performed before making the final connection of FADEC System components. The four

procedures that comprise the functional checks follow in subsequent subsections:

•

Electrical Ground Check

•

Enable Switch Check

•

Power Supply Check

•

Boost Pump Relay Check

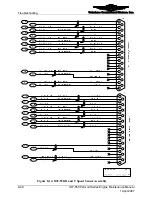

8-13.1. Electrical Ground Check

Procedure

1.

Master Power Switch ................................... OFF

2.

FADEC Primary Power Switch ................... OFF

3.

FADEC Secondary Power Switch ............... OFF

4.

Ignition Switch............................................. OFF

5.

Use a Digital Volt-ohm Meter (DVM) to measure between aircraft ground and the

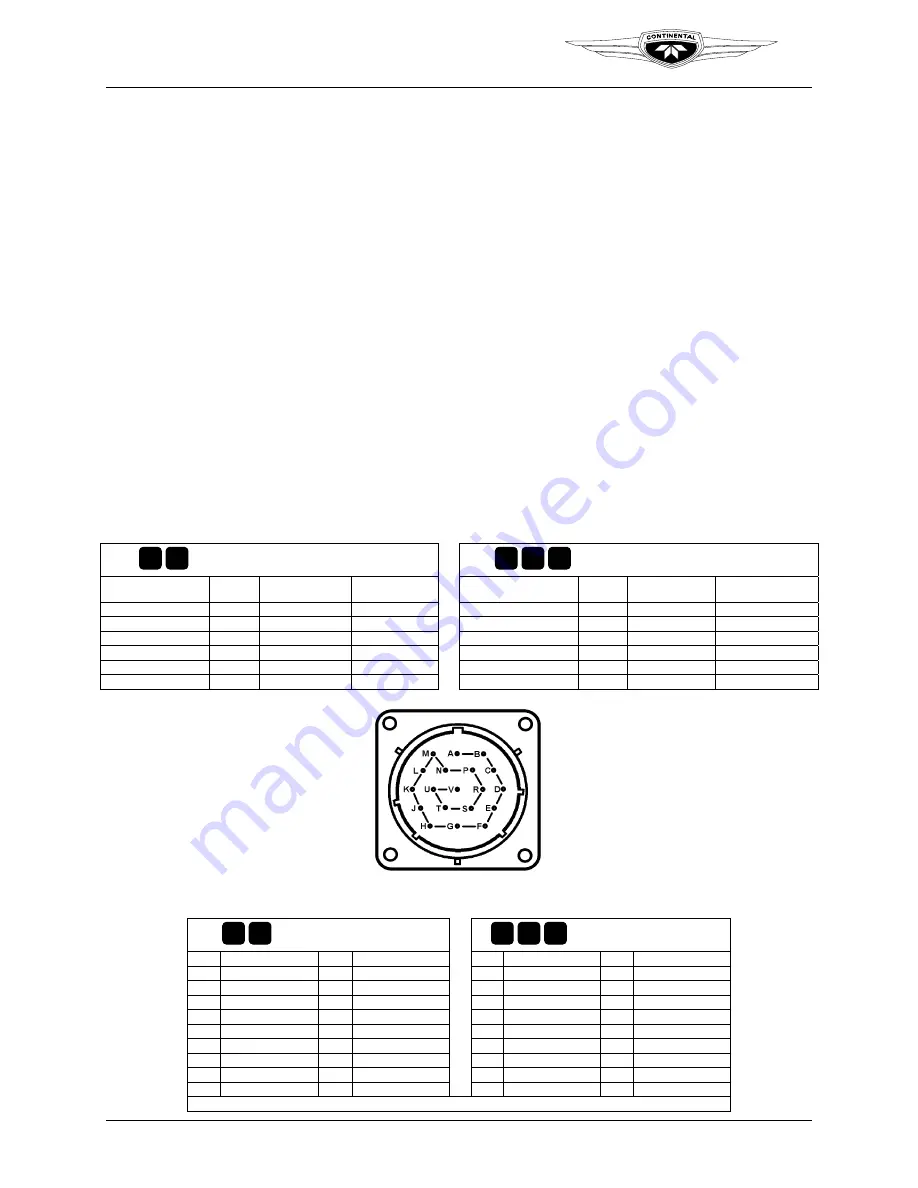

pins designated in the connector pin layout tables for P6, P7, and P8 respectively for

Figure 8-2 through Figure 8-4.

Connector Resistance Readings

Connector

Resistance

Readings

Plug Pin

Label

Resistance

Plug Pin

Label

Resistance

P6, P7, or P8

B

Ground

< 0.5

P6 or P7

B

Ground

< 0.5

P6, P7, or P8

D

Ground

< 0.5

P6 or P7

D

Ground

< 0.5

P6, P7, or P8

J

Enable

< 0.5

P6 or P7

E

Ground

< 0.5

P6, P7, or P8

K

Enable

< 0.5

P6 or P7

L

Enable

< 0.5

P6 or P7

S

Ground

< 0.5

P6 or P7

N

Enable

< 0.5

P6 or P7

V

Ground

< 0.5

P6 or P7

P

Enable

< 0.5

B C

N P R

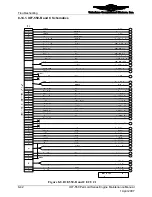

Figure 8-2.

P6 Connector Pin Layout

P6 Connector Signals

P6 Connector Signals

A

Primary Power

L

Mix 12 SIG

A

Primary Power

L

Enable A

B

Ground

M

Mix 12 RET

B

Ground

M

Fault 1

C

Secondary Power

N

Fuel Pump

C

Primary Power

N

Enable A

D Ground

P NC*

D Ground

P Fault

3

E

RS485A

R

Primary Power

E

Primary Power

R

Enable A

F RS485B

S Ground

F Ground

S Fault

5

G Fault

A

T *NC

G RS485A

T Mix

12

H

Fault B

U

Secondary Power

H

RS485B

U

Fuel Pump 1

J Enable

A

V Ground

J RS485A

V *NC

K Enable

B

K RS485B

*NC – Not Connected

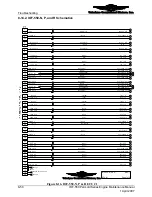

B C

N P R

8-36

IOF-550 Permold Series Engine Maintenance Manual

1 April 2007