Maintenance and Adjustments

Teledyne Continental Motors, Inc.

TM

9-28

IOF-550 Permold Series Engine Maintenance Manual

1 April 2007

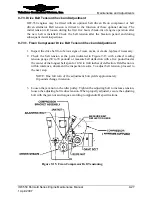

9-7.3.2. Alternator Drive Belt Tension Check and Adjustment

Procedure

1.

Inspect the drive belt for obvious signs of wear, nicks, or cracks; replace if necessary.

2.

Check the belt tension at the center of the span between the drive sheave and the

alternator with a Direct Reading Tension Gauge (Borroughs BT-33-73F) for 50-70

pounds of belt tension or no more than 0.11 inch deflection. If deflection is within

tolerance, document the inspection results. To adjust belt tension, proceed to step 3.

3.

Loosen the pivot bolt (7) securing the alternator (19) to the brace (15).

4.

Loosen the adjustment bolt (4) at the bottom of the brace (15).

5.

Loosen the mounting bolt (9), washer (2), and nut (3) at the top of the bracket (1) to

allow the alternator (19) to pivot freely.

6.

Adjust the belt tension until deflection is less than 0.11 inch and tighten the pivot bolt

(7). Torque the pivot bolt to Appendix B specifications.

7.

Torque the mounting bolt (9) and adjustment bolt (4) to Appendix B specifications.

8.

Safety wire the adjustment bolt (4) to an adjacent through bolt according to Appendix

B specifications.