Non-Overhaul Removal and Replacement

Teledyne Continental Motors, Inc.

TM

10-92

IOF-550 Permold Series Engine Maintenance Manual

1 April 2007

19.

Install the Induction and Exhaust System components according to instructions in

Chapter 11, Engine Assembly of the Overhaul Manual (OH-24) and applicable

airframe manufacturer’s instructions.

20.

Install the Fuel Injector according to instructions in Section 10-6.11.

21.

Install the Fuel Injector Solenoid according to instruction in Section 10-6.12.

22.

Set the aircraft Fuel Selector Valve to the ON position and activate the fuel boost

pump and leak check the fuel delivery system, including fuel lines and fittings.

23.

Service the engine with mineral oil by following the steps in the section “Oil Change

Procedure” in Chapter 9. Be sure to use mineral oil for cylinder break-in.

24.

Install the aircraft cowling and airframe-supplied accessories according to the

airframe manufacturer’s instructions.

25.

Perform the tasks listed in Chapter 6, Operational Performance Checks.

26.

Perform the steps in the “25-hour Initial Operation Inspection” in Chapter 7 at the

designated interval. When oil consumption has stabilized, replace the mineral oil with

ashless dispersant aviation engine oil by following the steps in the “Oil Change

Procedure” in Chapter 9.

10-8.8. IOF-550-N, P and R Engine Cylinder Installation

Procedure

1.

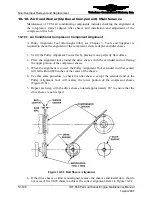

Refer to Figure 10-61; install a new cylinder base O-ring (59) lubricated with aviation

engine oil. (Verify the cylinder base O-ring is free of cracks and deformities.)

2.

Thoroughly clean the cylinder deck and stud threads with Stoddard solvent; use a

narrow brush to clean stud thread holes. The deck and stud holes must be free of all

dirt and debris.

3.

Lubricate all cylinder through bolt and deck stud threads using clean 50 weight

aviation engine oil.

4.

Verify the piston rings (56 through 59) have been installed on the piston and partially

installed in the cylinder bore and a new cylinder base O-ring (59), lubricated with

aviation engine oil, has been installed on the cylinder flange.

5.

Carefully rotate the crankshaft placing the connecting rod of the cylinder being

installed in the outer most position. Remove the O-ring that was installed for the

connecting rod support.

6.

Back the piston pin (60) out far enough to allow the piston (55) to be installed on the

connecting rod.

7.

Place the cylinder and piston (55) on the connecting rod.

8.

Line the piston up with the connecting rod and slide the piston pin into the connecting

rod.

9.

Using a ring compressor, compress the fourth piston ring and push the cylinder until

the fourth piston ring is positioned inside the cylinder barrel.

10.

Remove the ring compressor and push the cylinder assembly against the crankcase

cylinder deck with the stud holes aligned.