Non-Overhaul Removal and Replacement

Teledyne Continental Motors, Inc.

TM

10-106

IOF-550 Permold Series Engine Maintenance Manual

1 April 2007

10-10.

Air Conditioner (Optional Component) Maintenance

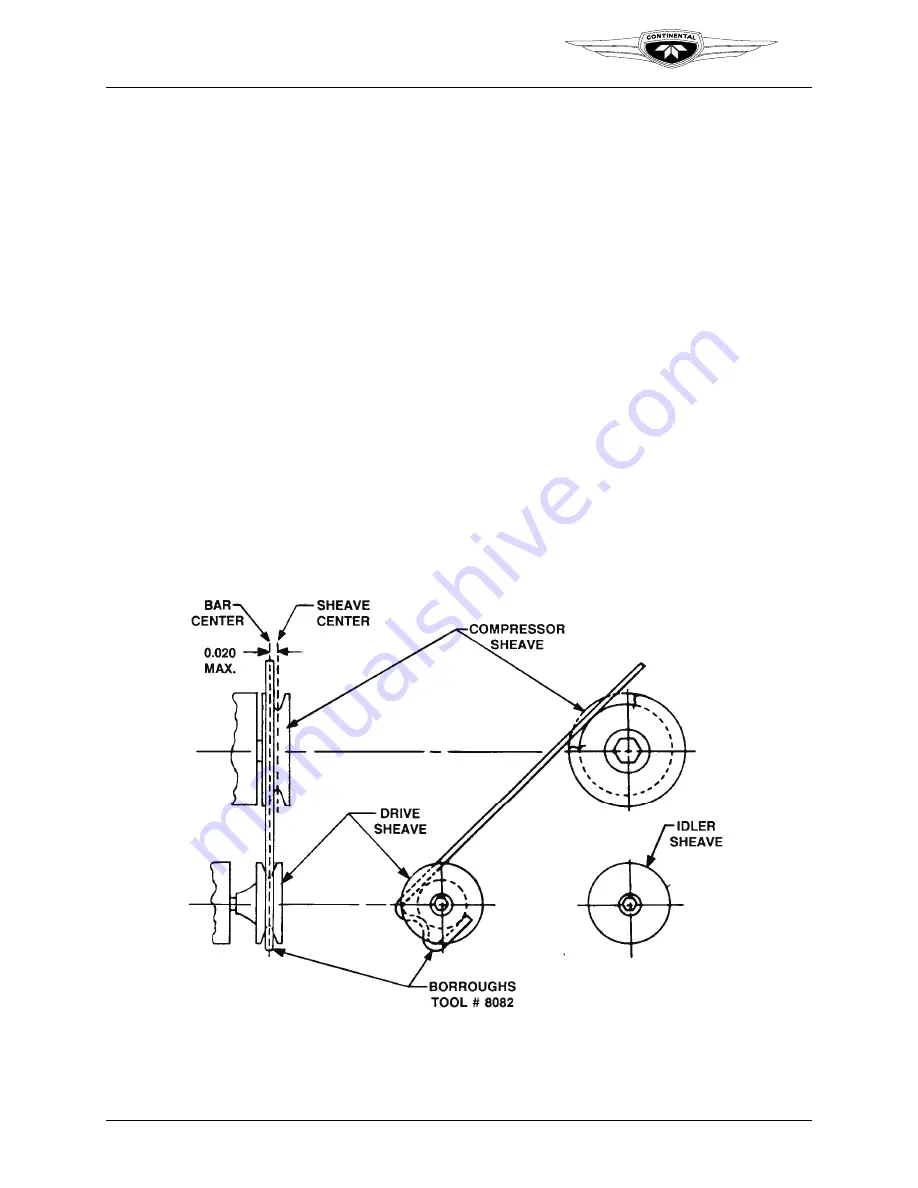

Maintenance of TCM air conditioning components includes checking the alignment of

the compressor, starter adapter, idler sheave and installation and adjustment of the

compressor drive belt.

10-10.1. Air Conditioner Compressor Component Alignment

A Pulley Alignment Tool (Borroughs 8082; see Chapter 3, Tools and Supplies) is

required to check the alignment of the compressor, starter adapter and idler sheave

Procedure

1.

Verify the Pulley Alignment Tool is flat by placing it on a perfectly flat surface.

2.

Place the alignment tool around the drive sheave with the extended end overlaying

the upper portion of the compressor sheave.

3.

When the alignment is correct, the Pulley Alignment Tool extended end (bar center)

will fall within 0.020 inches of the center of the sheave.

4.

Use this same procedure to check the idler sheave, except the extended end of the

Pulley Alignment Tool will overlay the lower portion of the compressor sheave

(Figure 10-81).

5.

Repeat each step with the drive sheave rotated approximately 90° to ensure that the

drive sheave is not warped.

Figure 10-81.

Belt Sheave Alignment

6.

If the drive sheave or idler is not aligned, remove the sheaves and install up to (but do

not exceed) five 0.020 shims to achieve the correct alignment. Refer to Figure 10-82.