Engine Description

Teledyne Continental Motors, Inc.

TM

2-20

IOF-550 Permold Series Engine Maintenance Manual

1 April 2007

permits a failure of the switch or wire to command a High Power Cruise or richer

mixture. If the airframe manufacturer chooses not to install a BP/BE switch, the FADEC

system will default to the Best Power mode when cruise parameters are met. The Engine

Control Panel incorporates the BP/BE switch function in the Best Economy Enabled

button.

2-2.5.6. Speed Sensor Array

The Speed Sensor Aray (SSA) provides the FADEC System with information about the

engine’s crank position and engine speed. The speed sensor array is a hall effect sensor.

The speed sensor array is mounted on the interior bottom of the oil sump. Two sealed,

circular electrical connectors installed in the oil sump walls, one on each side, conduct

signals from the speed sensor array to the ECU through the engine low voltage harness.

The IOF-550-B and C model engines use a signal conditioner mounted in the accessory

case to filter the signals from the speed sensor to the Electronic Control Units. The IOF-

550-N, P, and R incorporate the filter into the sensor array; no signal conditioner is

required on the IOF-550-N, P and R.

2-2.5.7. Cylinder Head Temperature Sensors

Each cylinder is equipped with a Cylinder Head Temperature (CHT) Sensor to monitor

the temperature of the cylinder within specified operating parameters.

The CHT Sensor is mounted on each engine cylinder via a bayonet style adapter which

threads into the cylinder head. A spring-loaded locking ring on the sensor reinforces this

attachment. The CHT Sensor is hardwired to the Engine Low Voltage Harness. Each

CHT Sensor is independent and operates for a respective engine cylinder.

The sensing element in the CHT Sensor is a thermistor. This type of device changes

resistance with temperature in a linear and repeatable manner. Measuring the resistance

of the sensor alloys enables an accurate determination to be made of the temperature at

the sensor tip.

2-2.5.8. Exhaust Gas Temperature Sensor

Exhaust Gas Temperature (EGT) Sensors report a temperature signal to the

corresponding control channel in the assigned ECU which monitors and controls that

engine cylinder. The ECU will use this signal to control the fuel-to-air ratio. The EGT

Sensors are hardwired to the Engine Low Voltage Harness. Each EGT Sensor is

independent and operates for a respective engine cylinder.

The sensing element in the EGT Sensor is a K-type thermocouple. Two conductors made

of dissimilar metals are fused to form the sensing element. The sensing element

resistance varies proportionally to temperature changes. The ECU monitors the resistance

variations detected at the sensor element tip. The EGT Sensors are installed in holes in

the exhaust system by means of a worm screw clamp.

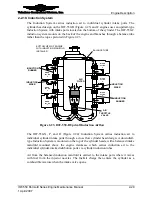

2-2.5.9. Manifold Air Pressure Sensor

The FADEC System utilizes two manifold air pressure (MAP) Sensors for measuring the

engine’s induction air pressure (manifold air pressure). The sensors are self-contained,

non-serviceable units that are thread-mounted into tapped bosses on the intake plenum on