Teledyne Continental Motors, Inc.

TM

Maintenance and Adjustments

IOF-550 Permold Series Engine Maintenance Manual

9-17

1 April 2007

9-4.

Ignition System Maintenance

9-4.1. Spark Plug Replacement

Procedure

1.

Remove the ignition harness leads from all spark plugs.

2.

Remove the spark plug from the top and bottom of each cylinder. Mark each plug’s

installed location during removal.

3.

Inspect the spark plug electrode condition using Figure 9-6 for spark plug

serviceability information. Discard any spark plugs which do not meet the “normal

electrode condition” characteristics.

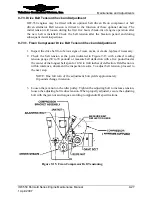

NORMAL ELECTRODE CONDITION

•

INSULATOR TIP GRAY, TAN OR LIGHT BROWN

•

FEW COMBUSTION DEPOSITS

•

ELECTRODES NOT BURNED OR ERODED

•

PROPER TYPE AND HEAT RANGE PLUG FOR

ENGINE AND SERVICE.

•

SPARK PLUG SHOULD BE CLEANED, REGAPPED

AND TESTED BEFORE REINSTALLTION

NORMAL WORN-OUT CONDITION

SEVERE WORN-OUT CONDITION

•

ELECTRODES ERODED BY HIGH VOLTAGE

SPARKING AND BY CORROSIVE GASES

FORMED DURING COMBUSTION TO LESS THAN

1/2 ORIGINAL THICKNESS

•

MORE VOLTAGE NEEDED TO FIRE SPARK

PLUGS - OFTEN MORE THAN IGNITION

SYSTEM CAN PRODUCE.

•

REPLACE WITH NEW APPROVED AVIATION

SPARK PLUGS.

•

EXCESSIVELY ERODED CENTER AND GROUND

ELECTRODES PLUS EXTENSIVE NECKING OF

FINE WIRE GROUND ELECTRODES INDICATE

ABNORMAL ENGINE POWER OR PLUGS

LONG OVERDUE FOR REPLACEMENT.

•

DISCARD SPARK PLUGS AND CHECK HEAT

RANGE BEFORE INSTALLING NEW ONES.

•

REPLACE WITH NEW APPROVED AVIATION

SPARK PLUGS IN APPROPRIATE HEAT RANGE.

FINE WIRE ELECTRODE

MASSIVE ELECTRODE

Figure 9-6.

Spark Plug Inspection Criteria

4.

Remove and discard the copper gasket from all reusable spark plugs.

5.

If a new spark plug is required, select one of those listed in Table 9-4 or the most

current version of SIL 03-2 “Currently Active Approved Spark Plug Application” to

determine the type of spark plugs to be installed.