Maintenance and Adjustments

Teledyne Continental Motors, Inc.

TM

9-18

IOF-550 Permold Series Engine Maintenance Manual

1 April 2007

Table 9-4.

Approved Spark Plug List

Manufacturer Part Number TCM Part Number Barrel Size GAP

CHAMPION

RHB32E

634675

¾”-20

.016” - .021”

RHB36S

646631

¾”-20

.016” - .021”

RHB32S

646632

¾”-20

.016” - .021”

AUTOLITE by UNISON

URHB32E

655908

¾”-20

.016” - .021”

BENDIX AUTOLITE

PL350 635148

¾”-20

.015”

-.018”

6.

Clean the spark plugs (new or re-used) as directed in the “Cleaning” section in

Chapter 9. Set the spark plug gap using manufacturer’s data for the appropriate part

number.

CAUTION: Failure to install a new spark plug gasket with the spark

plug may result in incomplete sealing of the combustion chamber,

loss of spark plug heat transfer, spark plug overheating, possible re-

ignition/detonation, and internal engine damage.

7.

Install a new copper gasket on all 12 spark plugs.

8.

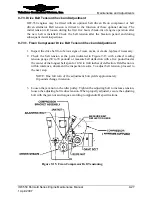

Refer to the spark plug rotation chart (Figure 9-7); mark serviceable spark plugs with

the respective “destination” positions. For all remaining locations, replace with a new

spark plug.

1

3

5

2

4

6

T

B

T

B

T

B

T

B

T

B

T

B

CYLINDER

NUMBER

CYLINDER

NUMBER

FROM

TO

1 TOP

6 BOTTOM

1 BOTTOM

6 TOP

SPARK PLUG ROTATION

2 TOP

5 BOTTOM

2 BOTTOM

5 TOP

3 TOP

4 BOTTOM

3 BOTTOM

4 TOP

4 TOP

3 BOTTOM

4 BOTTOM

3 TOP

5 TOP

2 BOTTOM

5 BOTTOM

2 TOP

6 TOP

1 BOTTOM

6 BOTTOM

1 TOP

1

3

5

2

4

6

T

B

T

B

T

B

T

B

T

B

T

B

CYLINDER

NUMBER

CYLINDER

NUMBER

FROM

TO

1 TOP

6 BOTTOM

1 BOTTOM

6 TOP

SPARK PLUG ROTATION

2 TOP

5 BOTTOM

2 BOTTOM

5 TOP

3 TOP

4 BOTTOM

3 BOTTOM

4 TOP

4 TOP

3 BOTTOM

4 BOTTOM

3 TOP

5 TOP

2 BOTTOM

5 BOTTOM

2 TOP

6 TOP

1 BOTTOM

6 BOTTOM

1 TOP

1

3

5

2

4

6

T

B

T

B

T

B

T

B

T

B

T

B

CYLINDER

NUMBER

CYLINDER

NUMBER

FROM

TO

1 TOP

6 BOTTOM

1 BOTTOM

6 TOP

SPARK PLUG ROTATION

2 TOP

5 BOTTOM

2 BOTTOM

5 TOP

3 TOP

4 BOTTOM

3 BOTTOM

4 TOP

4 TOP

3 BOTTOM

4 BOTTOM

3 TOP

5 TOP

2 BOTTOM

5 BOTTOM

2 TOP

6 TOP

1 BOTTOM

6 BOTTOM

1 TOP

Figure 9-7.

Spark Plug Rotation Chart