Maintenance and Adjustments

Teledyne Continental Motors, Inc.

TM

9-24

IOF-550 Permold Series Engine Maintenance Manual

1 April 2007

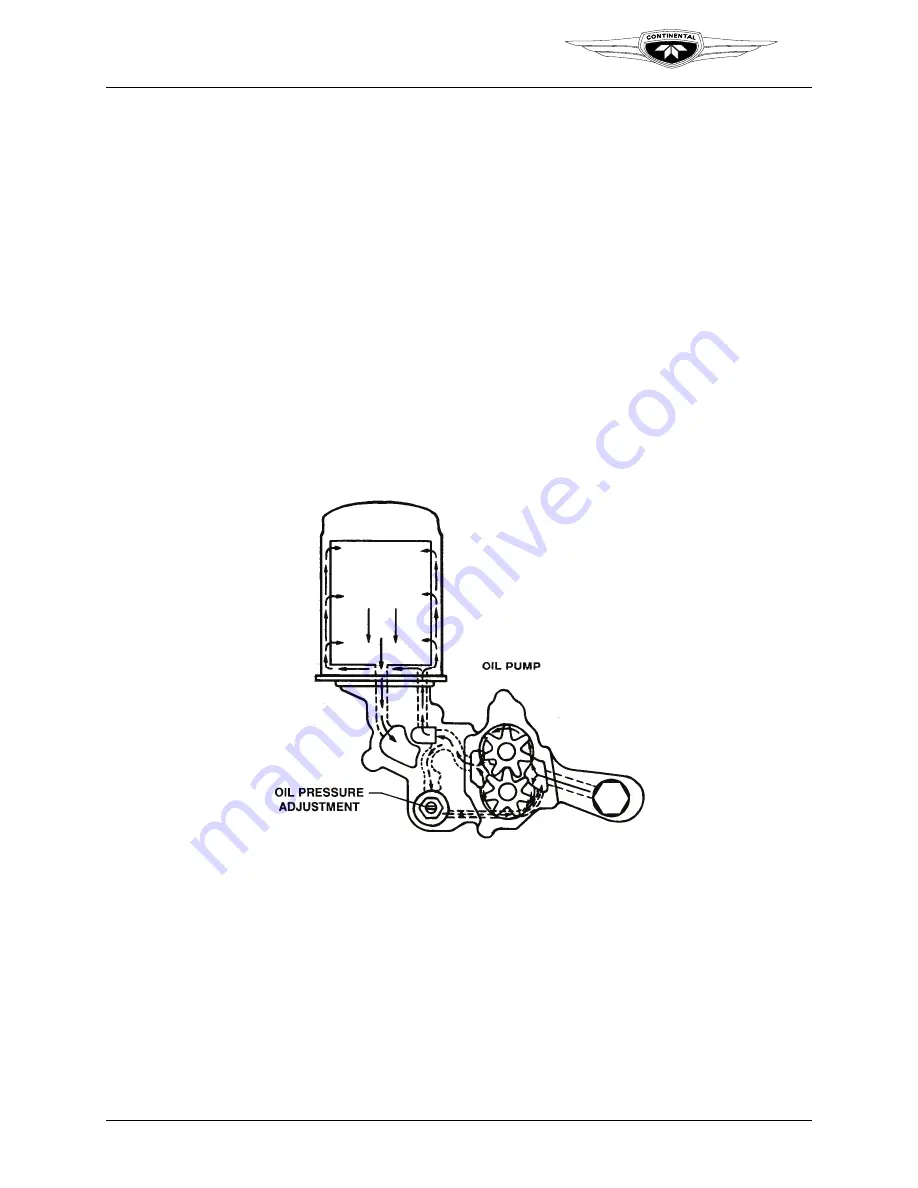

9-7.1. Oil Pressure Adjustment

Procedure

1.

Prepare the aircraft for ground run up and start the engine as directed in the section

“Engine Start” in Chapter 7, Engine Operation in the Installation and Operation

Manual (OI-24).

2.

Allow the engine to reach the operating temperature designated in “Engine

Specifications and Operating Limits” in Chapter 2.

3.

Shut down the engine.

4.

Loosen the lock nut securing the oil pressure adjustment screw at the base of the oil

pump.

5.

Adjust oil pressure to maintain 30-60 psi at full power RPM. To

increase

oil pressure,

turn the oil pressure adjusting screw

clockwise

(CW) (Figure 9-12). To

decrease

oil

pressure, turn the oil pressure adjusting screw

counterclockwise

(CCW).

6.

Torque the lock nut per Appendix B and safety according to instruction in Appendix

C.

Figure 9-12.

Adjustment Screw on the Oil Pressure Relief Valve