Teledyne Continental Motors, Inc.

TM

Maintenance and Adjustments

IOF-550 Permold Series Engine Maintenance Manual

9-27

1 April 2007

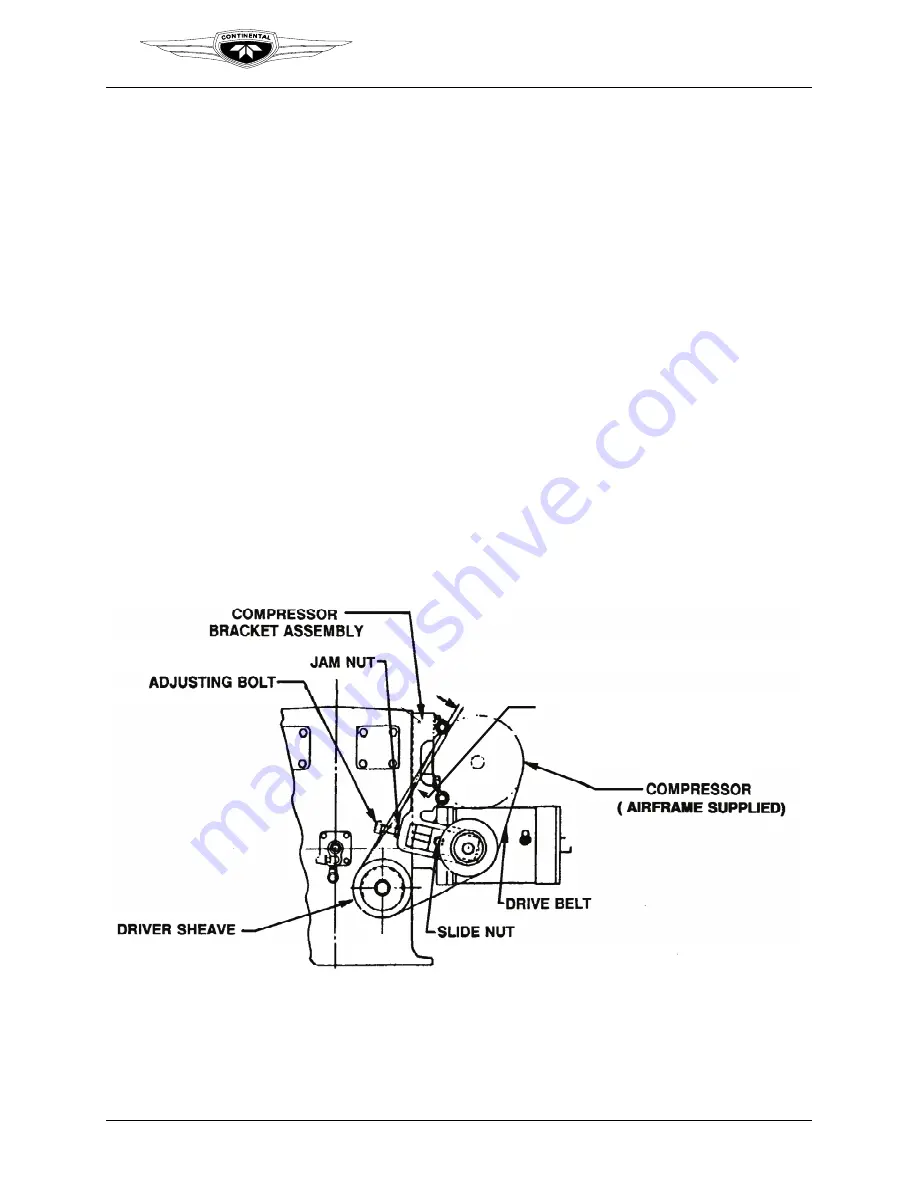

9-7.3. Drive Belt Tension Check and Adjustment

IOF-550 engines may be fitted with an optional belt driven Freon compressor or belt

driven alternator. Belt tension is critical to the function of these optional devices. The

initial tension will loosen during the first five hours (break-in) of engine operation after

the new belt is installed. Check the belt tension after the break-in period and during

subsequent visual inspections.

9-7.3.1. Freon Compressor Drive Belt Tension Check and Adjustment

Procedure

1.

Inspect the drive belt for obvious signs of wear, nicks, or cracks; replace if necessary.

2.

Check the belt tension at the point indicated in Figure 9-15 with a direct reading

tension gauge (50 to 70 pounds) or measure belt deflection with a five pound load at

the center of the longest belt span for 0.30 to 0.40 inches of deflection. If deflection is

within tolerance, document the inspection results. To adjust belt tension, proceed to

the next step.

NOTE: One full turn of the adjustment bolt yields approximately

10 pounds change in tension.

3.

Loosen the jam nut on the idler pulley. Tighten the adjusting bolt to increase tension,

loosen the adjusting bolt reduce tension. When properly adjusted, secure the adjusting

bolt with the jam nut and torque according to Appendix B specifications.

MEASURE BELT

DEFLECTION HERE

MEASURE BELT

DEFLECTION HERE

Figure 9-15.

Freon Compressor Belt Tensioning