Non-Overhaul Removal and Replacement

Teledyne Continental Motors, Inc.

TM

10-12

IOF-550 Permold Series Engine Maintenance Manual

1 April 2007

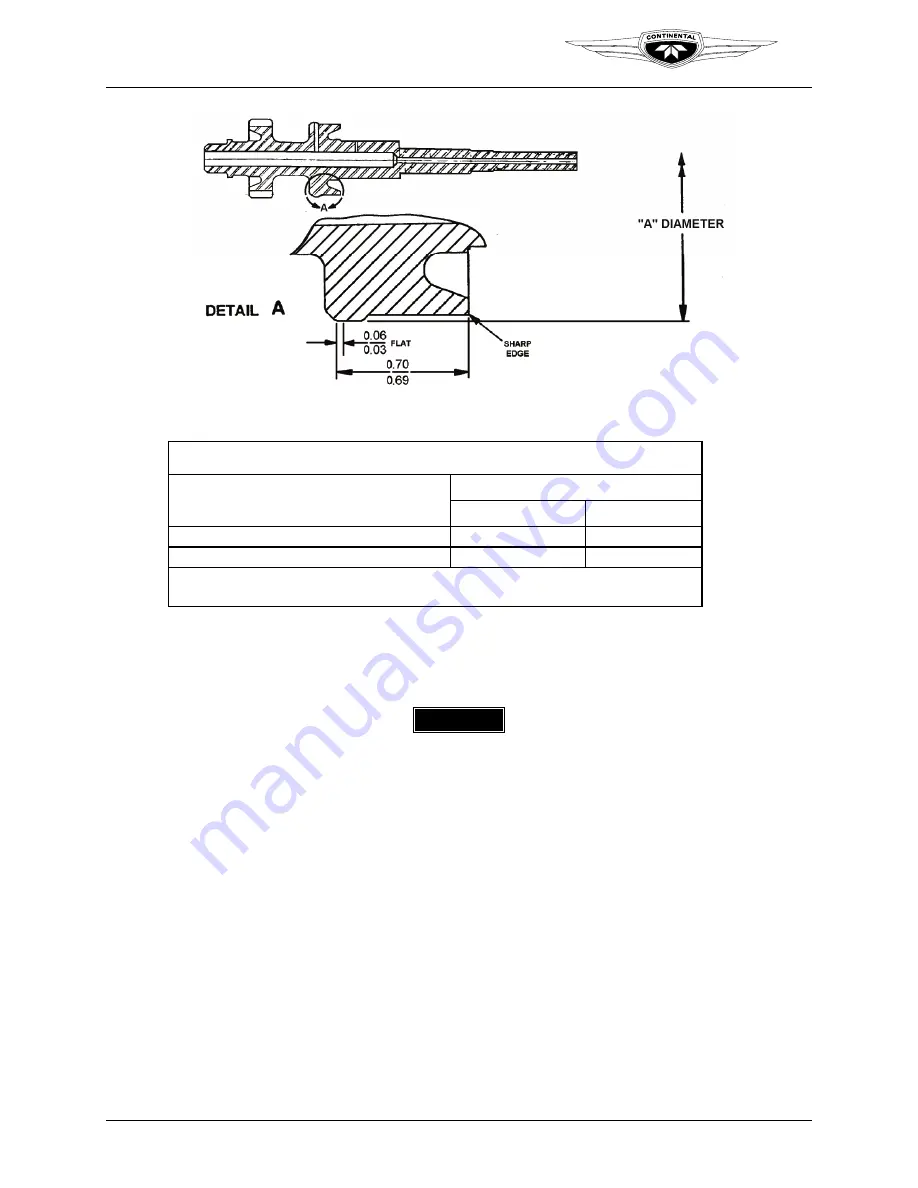

Figure 10-5.

Shaft Gear Drum Dimensions

Table 10-7.

Shaft Gear Drum Dimensions: Fits and Limits

“A” Diameter (inches)

Part

Minimum Maximum

New Shaft Gear Drum Dimensions

1.931

1.932

0.015 Undersize

1.916

1.917

NOTE: Inspect the start adapter sleeve. The outside diameter should be .812 to .814

inches.

10-3.4. Starter Adapter Installation

Procedure

WARNING

If all power is not disconnected, a loose or broken wire could

allow the engine to start and the propeller to rotate. Do not

stand or place equipment within the arc of the propeller.

1.

Disconnect engine electrical power; turn the Master Power and Ignition Switches to

the OFF positions.

2.

Thoroughly clean the crankcase mounting surface to remove any gasket residue.

CAUTION: Do not apply an excessive amount of Gasket Maker to

avoid contaminating the oil supply.

3.

Apply a translucent coat of TCM Gasket Maker (per instructions in Appendix C) to

the starter adapter gasket crankcase mating surface only.

4.

Install the new gasket on the crankcase.

5.

Lubricate the teeth on the starter shaft gear with clean 50-weight aviation engine oil.

6.

Mesh the teeth with the crankshaft gear while placing the starter adapter in position.