Teledyne Continental Motors, Inc.

TM

Non-Overhaul Removal and Replacement

IOF-550 Permold Series Engine Maintenance Manual

10-47

1 April 2007

11.

For proper operation of the engine, route, clamp, support, and protect the wires in the

engine low voltage harness in a manner to prevent chafing, fretting, and wear of the

lead wires. Route and secure the harness IAW Appendix C, “Harness Routing.”

12.

Perform a “FADEC Level I Diagnostics” in Chapter 8, Troubleshooting of this

manual to check the FADEC System. If the FADEC System fails this diagnostic

check, troubleshoot the system until the malfunction is corrected.

13.

Upon completion of maintenance, perform an “Engine Operational Check” according

to the instructions in Chapter 6, Operational Performance Checks.

10-6.10. Fuel Injector Removal

WARNING

Use care to avoid fuel injector contamination. Work with clean

hands, tools, and shop towels. Place protective caps on open

fuel system connections.

Procedure

1.

Set the aircraft Fuel Selector Valve to the OFF position.

NOTE: Do not remove the cable tie from the injector support

bracket unless it is damaged or incorrectly installed.

2.

Cut and remove cable ties necessary remove the fuel injector solenoid coil.

3.

While holding the injector body with one wrench, loosen the fuel line B-nut with

another wrench.

CAUTION: Fuel may flow from the fuel line once it is disconnected

from the fuel injector body. Place a small container beneath the

open end of the fuel line to capture this fuel.

4.

Place a clean protective cap on the fuel line to prevent contamination.

5.

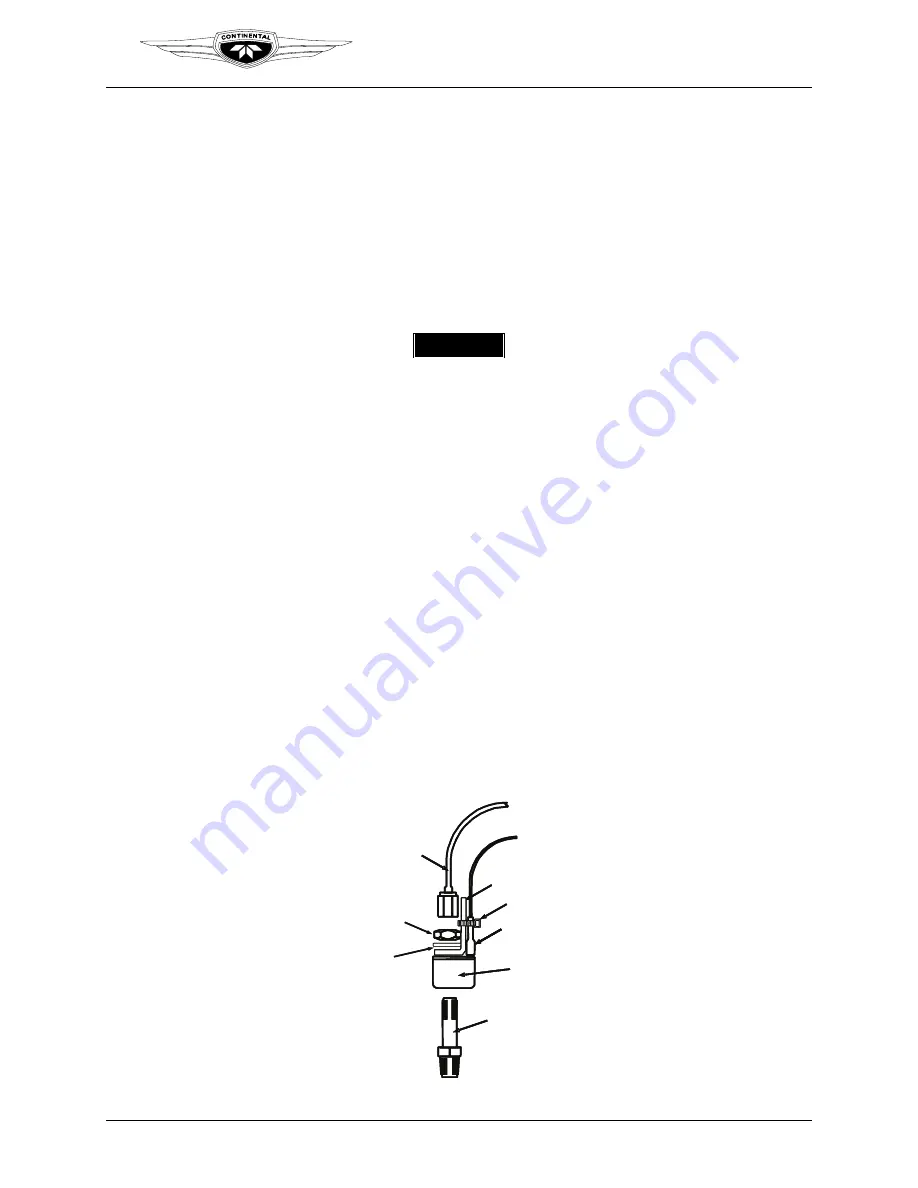

Remove the retaining nut (Figure 10-42) and washer which secures the solenoid coil.

WASHER

INJECTOR BODY

SOLENOID COIL

LEAD WIRE

FUEL LINE

RETAINING NUT

TIE STRAP

SUPPORT

WASHER

INJECTOR BODY

SOLENOID COIL

LEAD WIRE

FUEL LINE

RETAINING NUT

TIE STRAP

SUPPORT

Figure 10-42.

FADEC Fuel Injector Assembly