Teledyne Continental Motors, Inc.

TM

Non-Overhaul Removal and Replacement

IOF-550 Permold Series Engine Maintenance Manual

10-59

1 April 2007

10-6.28. EDI Replacement

EDI installation instructions are dependent upon aircraft make and model. Refer to the

applicable aircraft maintenance manual for EDI location and removal and installation

instructions.

10-6.29. ECP Replacement

ECP installation instructions are dependent upon aircraft make and model. Refer to the

applicable aircraft maintenance manual for ECP location and removal and installation

instructions.

10-7.

Lubrication System Repair

10-7.1. Oil Filter Adapter Stud Replacement

Procedure

1.

Disconnect electrical power to the engine; verify the Ignition Switch is turned OFF.

WARNING

If the power is not turned OFF, a loose or broken wire could

cause the engine to start and the propeller to rotate. As a

precaution, do not stand or allow anyone else to stand within

the arc of the propeller.

2.

Remove the oil filter adapter stud.

3.

Inspect the threads in the adapter housing for damage or cracks. If any thread damage

or crack is evident, remove the adapter housing and install a new adapter housing.

4.

Clean the adapter housing threads thoroughly to remove any remaining thread

adhesive and oil.

5.

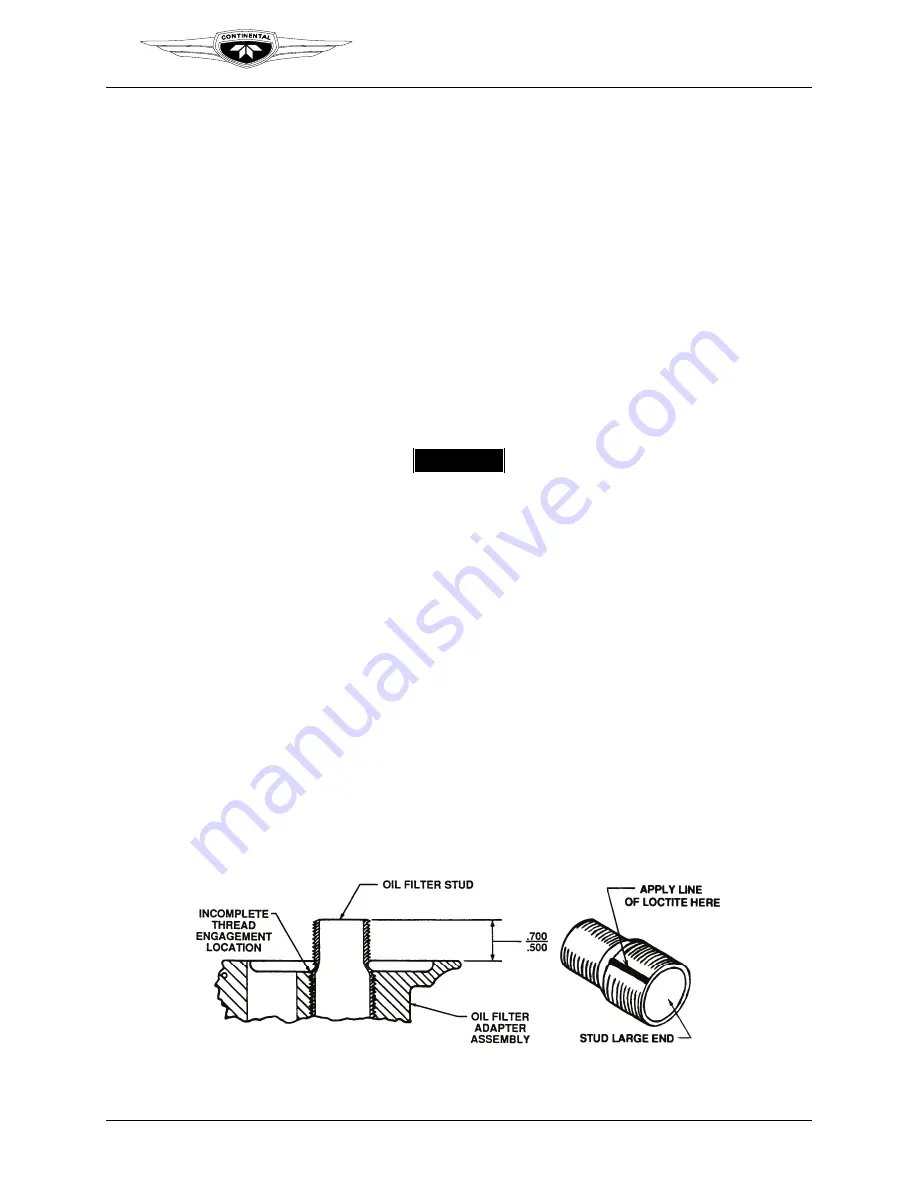

Do not apply Loctite at this time. Install the new oil filter adapter stud (Figure 10-50).

(This stud is 1.440-inch (36.6 mm) in length uninstalled.)

6.

Verify the incomplete thread on the new oil filter adapter stud stops at the first thread

in the adapter housing and does not continue into the housing below the minimum

.500-inch (12.7 mm) extension. If the extension is less than .500-inch (12.7 mm),

replace the adapter housing.

Figure 10-50.

Oil Filter Stud Height