Non-Overhaul Removal and Replacement

Teledyne Continental Motors, Inc.

TM

10-60

IOF-550 Permold Series Engine Maintenance Manual

1 April 2007

7.

Once proper stud depth is verified, remove the oil filter adapter stud from the adapter

housing.

8.

Clean the threads of the adapter housing and stud with Loctite "Primer T" and allow

to dry.

9.

Apply a line of Loctite 271 along the large threads (.8125-16 end) of the oil filter

adapter stud and install the stud into the adapter housing to the bottom of the stud’s

first incomplete thread. Torque according to Appendix B.

10.

Repeat stud height verification (Figure 10-50).

11.

Allow the parts to cure for a minimum of thirty minutes prior to oil filter installation.

Cure times may vary depending on ambient temperature, consult the Loctite

instructions.

12.

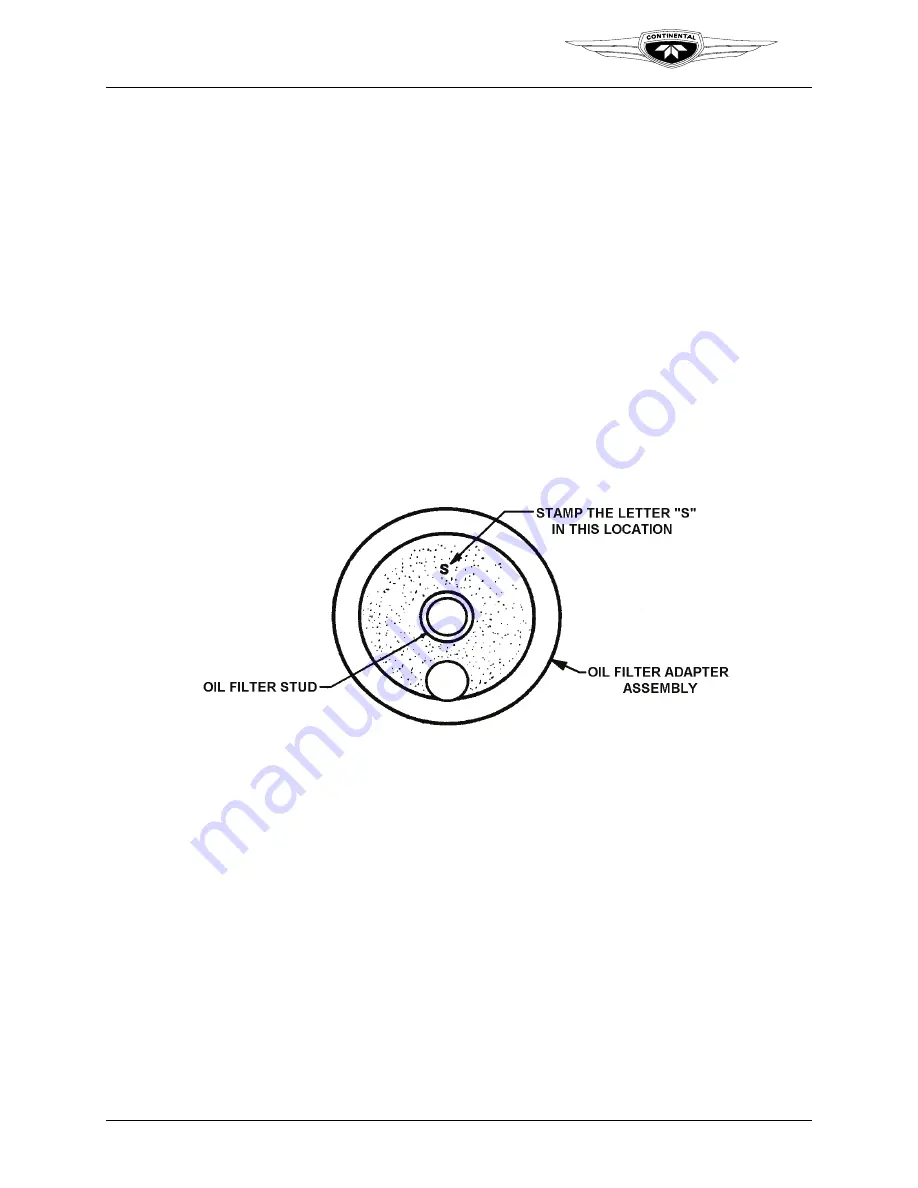

Stamp a .125-inch high letter "S" in the adapter housing as shown in Figure 10-51 to

indicate a new oil filter adapter stud has been installed in the adapter housing.

13.

Check the lubrication system for oil leaks and perform the oil pressure checks and

adjustments listed in Chapter 6, Operational Performance Checks.

Figure 10-51.

New Stud Identification in the Oil Filter Adapter Housing