Teledyne Continental Motors, Inc.

TM

Non-Overhaul Removal and Replacement

IOF-550 Permold Series Engine Maintenance Manual

10-99

1 April 2007

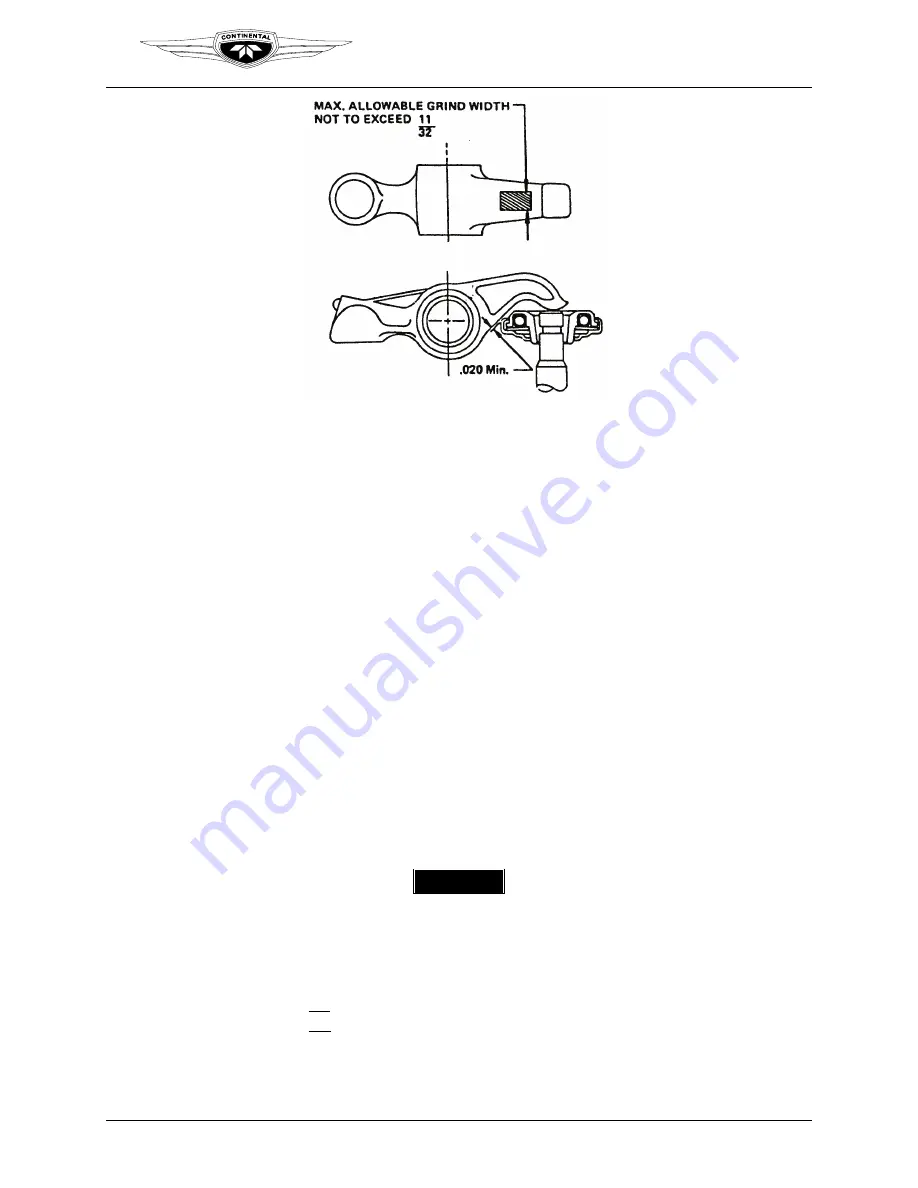

Figure 10-75.

Rocker Arm-to-Rotocoil Clearance

CAUTION: Do not over- or under-torque bolts to align tab

washers; replace the bolt and re-torque to obtain proper alignment.

10.

Secure the rocker assembly to the cylinder by bending the new tab washers (26)

(Figure 10-61) flat up against the head of the screws (27) per instructions in Appendix

C, Standard Practices for installing tab washers. Do not re-align the screw head to the

tab washer.

11.

Measure the dry valve gear lash at valve tip-to-rocker foot with the piston at top dead

center and compare with limits given in Appendix D for engine cylinders. Replace the

pushrods with authorized over sized pushrods (P030) if the dry lash exceeds the limit.

12.

Install new rocker cover gaskets (28) (with the beaded side of the gasket toward the

rocker cover) and the rocker covers (29); secure them with screws (32), new lock

washers (31) and washers. Torque the rocker cover fasteners to Appendix B

specifications.

10-9.

Crankcase Repair

Cracks occur on the cast aluminum crankcases for various reasons (e.g., improper

crankcase assembly or maintenance).

WARNING

Do not allow a cracked crankcase that exhibits the damage

described below to remain in service. Engine failure is

imminent if the conditions persist.

CAUTION:

All

cracks require attention, regardless of size or

location. Do not ignore crankcase cracks.

10-9.1. Crankcase Repair and Replacement Criteria

The following criteria should be applied for repair and replacement of crankcases: