Non-Overhaul Removal and Replacement

Teledyne Continental Motors, Inc.

TM

10-108

IOF-550 Permold Series Engine Maintenance Manual

1 April 2007

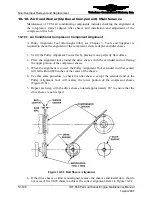

Figure 10-83.

Belt Tensioning

5.

Tighten the adjusting bolt two full turns to attain 50 to 70 pounds belt tension. One

full turn of the adjusting bolt yields approximately 10 pounds change in belt tension.

CAUTION: Do not over tension the drive belt.

6.

Torque the adjusting bolt jam nut and idler sheave screw per Appendix B of this

manual.

7.

Confirm that belt tension is 50-70 pounds by one of the following methods:

a.

Use a direct reading Belt Tension Gauge such as Borroughs Tool Number

BT-33-73F or equivalent.

b.

Apply a five pound load at the center of the longest belt span. Measure belt

deflection at the center of the load point. Correct deflection should not exceed

0.30- 0.40 inches.

8.

If the belt tension is not within the specified tolerance, loosen the jam nut and slide

nut and repeat steps 6-9.

9.

After approximately 5 hours of operation with the new belt, check the belt tension

and adjust as required to maintain 50 to 70 pounds of belt tension.

10-11.

Engine Preservation and Storage

Engine Preservation and storage instructions are in Chapter 6 of the TCM Installation and

Operation Manual (OI-24).