ENGLISH

CONTRACOR

®

CAB-110S/CAB-135S Art. 15105/15106

13

ATTENTION!

Always close cabinet, reclaimer and dust collector doors before blasting.

Keep all doors closed during blasting.

Always wear blast gloves.

Avoid pointing the blast nozzle toward the view window.

Use the blow-off nozzle to blow media off parts before opening doors.

After blasting, keep doors closed and exhauster on until the cabinet is

clear of all airborne dust.

Stop blasting immediately if dust leaks are detected.

4.2.4. Blasting operation

Open the compressed air supply to the blast cabinet. On the initial start up check for

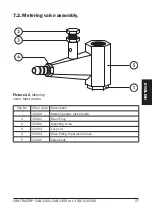

air leaks. Adjust the pulse pressure regulator to 4,5 bar (see drawing X for location).

Turn on/of switch to the position “I” to switch on the lights and ilter pulse cleaning.

Push button ON to switch on the exhauster. Insert hands into rubber gloves. Firmly grasp

the blast gun and step on the foot pedal. Blasting will begin immediately. Adjust blast

pressure using pilot regulator located on the control panel. Pressure gauge on the control

panel shows actual blast pressure value.

Most effective blasting techniques are smooth continuous strokes. The distance from

the part affects size of blast pattern. Normal practice places the nozzle approximately 70 to

150mm from the surface of the part.

ATTENTION!

Shut down the cabinet immediately if dust discharges from the collector.

Check that ilters are correctly seated and not worn or damaged.

Prolonged breathing of any dust could result in serious lung disease

or death. Short term ingestion of toxic dust such as lead, poses an

immediate danger to health. Toxicity and health risk vary with dust

generated by blasting. Identify all material being removed by blasting, and

obtain a material safety data sheet for the media.