Application manual for YRB-4EML-31S safety relay

Contrinex AG Industrial Electronics

15

F Frequency and duration

<

1 hour

5

> 1 hour to < 1 day

5

> day to < 2 weeks

4

> 2 weeks to < 1 year

3

> 1 year

2

W Probability of a hazardous event

Frequent

5

Probable

4

Possible

4

Seldom

3

Negligible

2

2.3

Practical procedure according to EN ISO 62061

In practice, the following steps have proven effective when designing safe controllers

according to EN 62061.

2.3.1

Specification of requirements for the safety-related control

function (SRCF)

The safety function must be defined first. This information is derived from the risk

assessment.

Example:

Trigger event:

Opening the safety door.

Response:

The robot drive is set to a safe stop state. The power

semiconductor pulses are disabled.

Safe state:

Power circuit has no power.

2.3.2

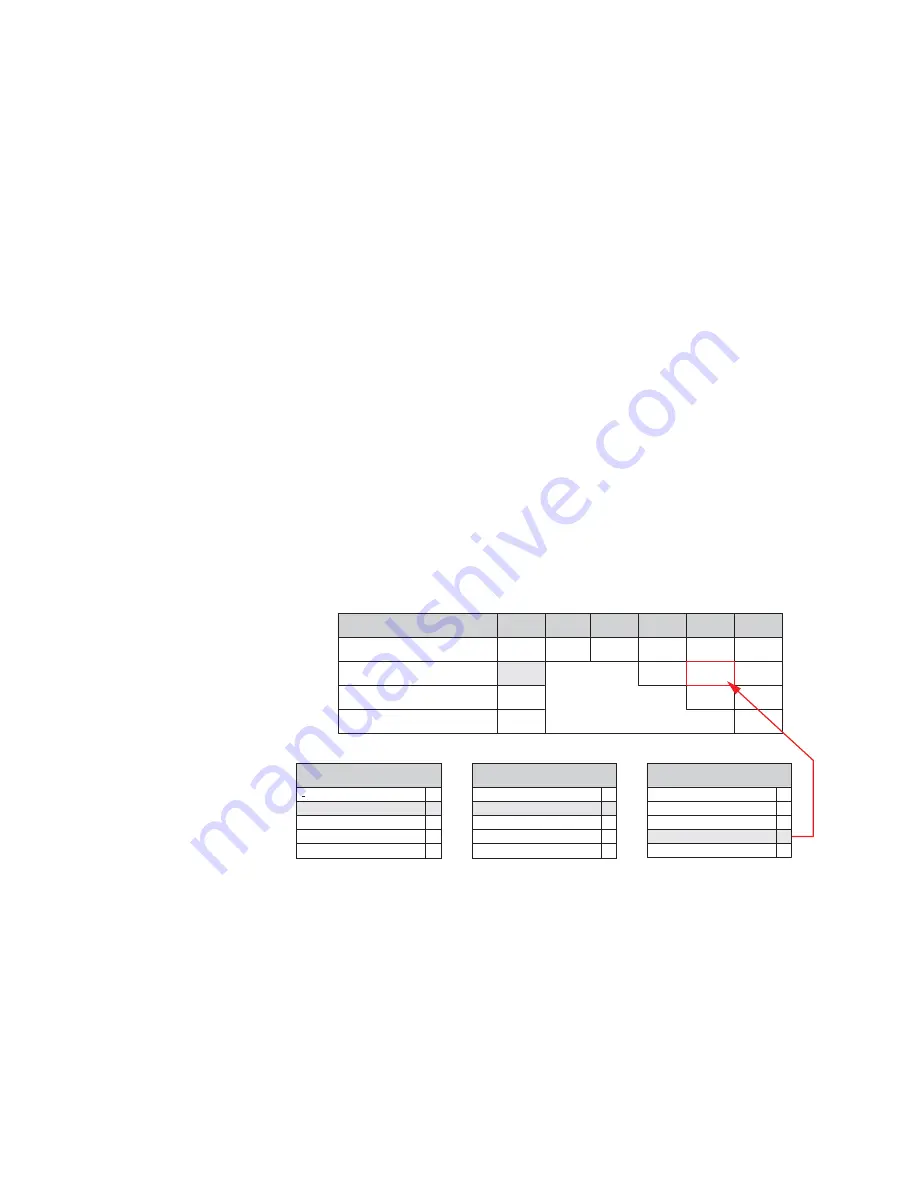

Determination of the required safety integrity level (SIL)

The required SIL is determined in combination with the safety function within the framework

of the higher-level risk assessment.

Effect

Severity

Class

Class

Class

Class

Class

S

3 - 4

5 - 7

8 - 10

11 - 13

14 - 15

Death, loss of an eye or arm

Permanent, loss of fingers

4

SIL 2

SIL 2

SIL 2

SIL 3

SIL 3

3

SIL 1

SIL 2

SIL 3

Reversible, medical treatment

Reversible, first aid

2

Other measures

1

SIL 1

SIL 3

SIL 1

P Avoidance

+

+

Impossible

4

Possible

3

Probable

2

Figure 5

Example of specifying the SIL (according to EN 62061)

2.3.3

Drafting the safety-related electrical control system

(SRECS)

This step involves the technical pre-planning of the safety function, taking possible

technologies and components into account. The safety-related components and parts must

then be identified for later verification.