Application manual for YRB-4EML-31S safety relay

Contrinex AG Industrial Electronics

16

2.3.4

Determination of the achieved safety integrity for the entire

SRECS

To determine the achieved safety integrity level, the PFH

d

values of the individual

subsystems must now be added together. The result must lie within the SIL required for the

safety function.

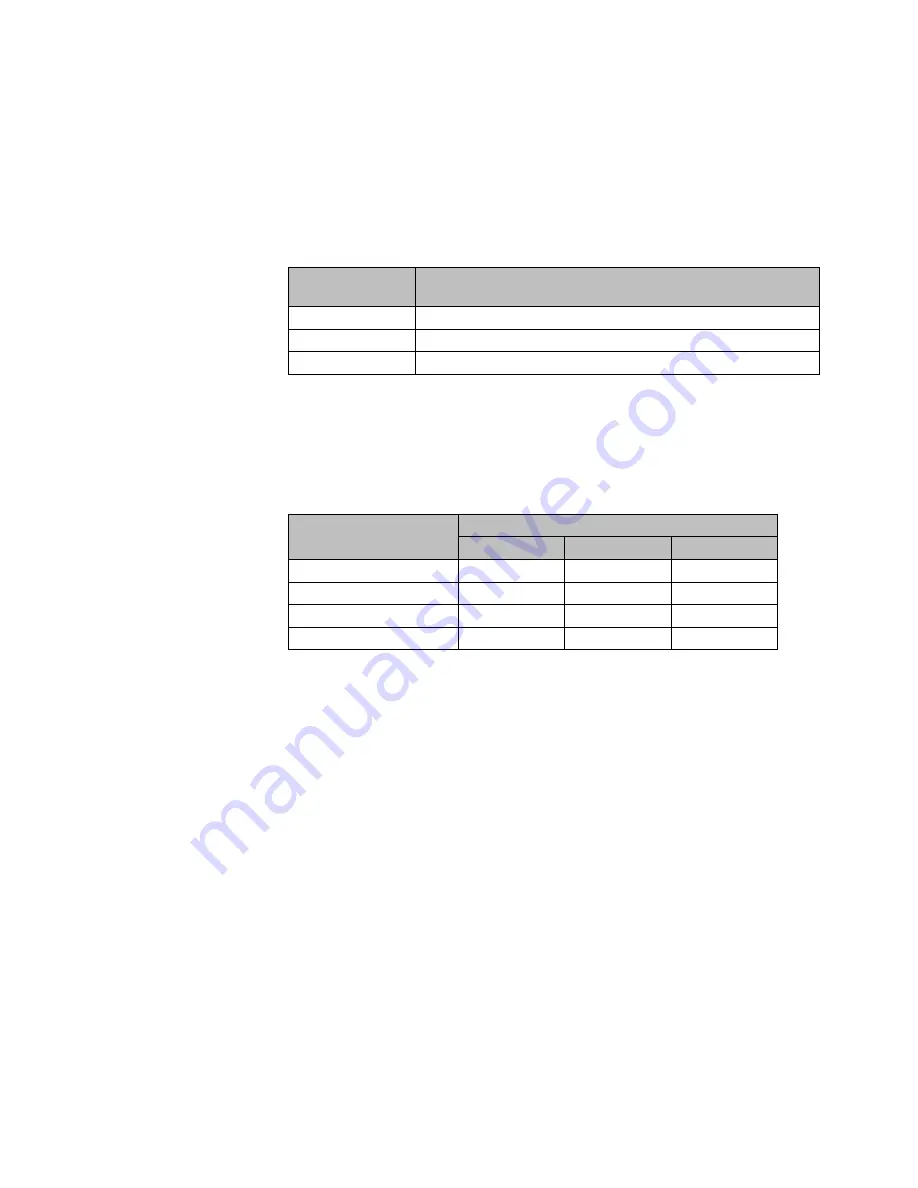

Table 2

Determination of the safety integrity level (according to EN 62061)

Safety

integrity level

Probability of a dangerous failure per hour (PFH

D

)

3

≥ 10

-8

to < 10

-7

2

≥ 10

-7

to < 10

-6

1

≥ 10

-6

to < 10

-5

Furthermore, the SIL CL of an individual subsystem determines the maximum achievable

SIL for the SRECS. For safety components with integrated diagnostics, this is provided by

the manufacturer. For subsystems consisting of discrete components, this value must be

determined using the table below.

Table 3

Determination of the safety integrity level for a subsystem with discrete

components (according to EN 62061)

Safe failure fraction

Hardware fault tolerance

1)

0

1

2

< 60%

Not permitted

2)

SIL 1

SIL 2

60% to < 90%

SIL 1

SIL 2

SIL 3

90% to < 99%

SIL 2

SIL 3

SIL 3

≥ 99%

SIL 3

SIL 3

SIL 3

1)

A hardware fault tolerance of N means that N + 1 faults can lead to a loss of the SRCF.

2)

See EN ISO 62061, Section 6.7.7

2.3.5 Verification of the achieved SIL

Each individual subsystem and the entire safety chain must both meet the requirements of

the necessary SIL. This includes both the quantitative evaluation and the consideration of

systematic aspects.

The systematic aspects include:

– Correct dimensioning of components

– Consideration of expected operating conditions and ambient conditions

– Use of basic and proven safety principles

– Avoidance of specification errors and software errors through testing