© 2020

CONTRIVE • B1444

|FIRO.EN

10

20

1

www.contrive.it

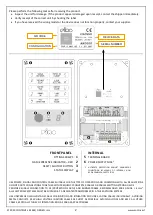

AUTOMATIC BURNER CONTROL SYSTEM

The burner control unit FIRO is suitable for the control

of industrial burners up to 350 kW, pursuant to EN

746

-2, for intermittent or continuous operation.

Flame control by means of ionization rod (even shared

with ignition).

Advanced self-diagnostic system provides the display

of either the cycle status, the causes that produced

lockouts or the immediate diagnostic of the failures

that affect the equipment or the burner.

Firo provides lockout output and remote reset input.

Times and operating cycle are configurable: the same

device can be used to control different types of gas

burners, meeting all relevant requirements.

The pull-out terminal blocks allow the control device

to be easily replaced during maintenance operations.

SAFETY INFORMATION

Read and understand this manual before installing, operating, or servicing this unit. This unit must be installed

according to this manual and local regulations. The drawings may show units without covers or safety shields to

illustrate details. Disconnect power supply and follow all usual safety precautions before carrying out any operation

on the device.

Be sure to reinstall covers or shields before operating any devices

.

The device is not user serviceable, a faulty device must be put out of order and sent back for servicing.

CONTRIVE manufactures products used as components in a wide variety of industrial systems and equipment. The

selection and application of products remain the responsibility of the equipment manufacturer or end user.

CONTRIVE accepts no responsibility for the way its products are incorporated into the final system design. All

systems or equipment designed to incorporate a product manufactured by CONTRIVE must be supplied to the end

user with appropriate warnings and instructions as to the safe use and operation of that part.

Any warnings provided by CONTRIVE must be promptly provided to the end user.

CONTRIVE guarantees for two years from the date of manufacture of its product to replace, or, at its option, to

repair any product or part thereof (except fuses and with some limitations for tubes and photocells) which is found

defective in material or workmanship or which otherwise fails to conform to the description of its sales order.

CONTRIVE makes no warranty of merchantability or any other warranty express or implied. CONTRIVE assumes no

liability for any personal injury, property damage, losses, or claims arising from misapplication of its products.

CERTIFICATION

Gas Equipment Directive (2009/

142

/EC)

Low Voltage Equipment Directive (

2014

/35/EC)

EMC Directive (

2014

/30/EC)

IN CONJUNCTION WITH:

EN298 –

EN746

-2 –

EN60730

-

1

–

EN13611