© 2009 CONTRIVE • B1401|400.EN

0211

11

www.contrive.it

Q512 – FLAME LOSS

Determines the behavior at flame loss during normal burner operation.

For burners with occasionally unstable flame signal a single recycle (including

prepurge) or direct respark can be attempted. The setting is to be determined on

the basis of burner capacity and relevant application standard.

Q602 – POSTPURGE TIME

Follow EN 676 requirements to set correct postpurge time in forced draught

burners. Any air valve and/or butterfly valve controlled by external process must

be kept open during the whole postpurge time.

During this time an illegal flame test is carried out.

Q801 – BURNER TYPE

Selecting OIL type burner the ignition device will be activated also during the

prepurge to allow the detection of oil leakage that will be ignited, leading to an

illegal flame detection. Application and settings must be made in accordance to

EN 230 (or other relevant standard) requirements.

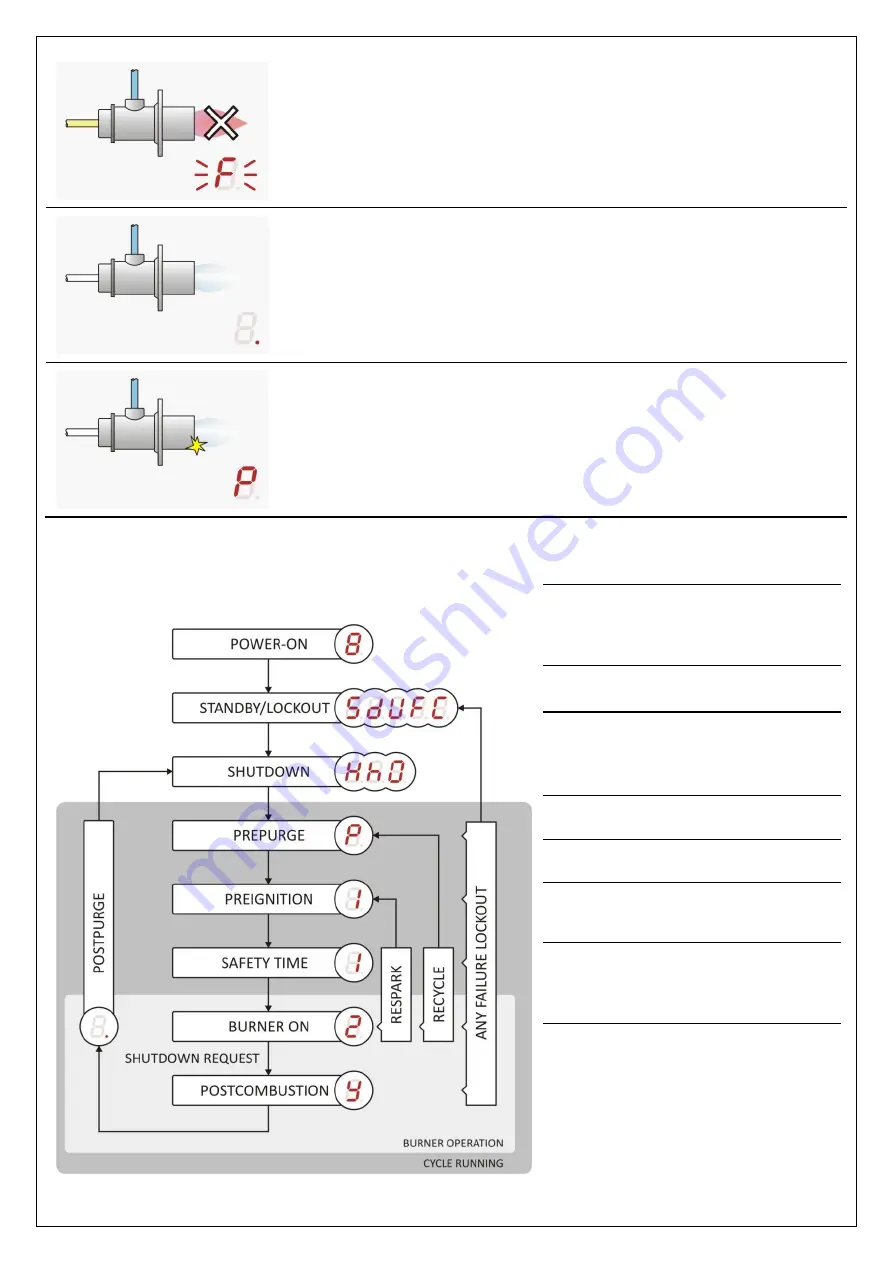

A

SELF TEST

IS PERFORMED IN LESS THAN 1”,

ONCE SUCCESSFULLY COMPLETED THE BURNER

IS READY TO START.

IF THE UNIT HAS BEEN TURNED OFF WHILE IN

LOCKOUT

OR PARAMETER Q101 HAS BEEN SET

TO

STANDBY

, IT WILL BE NECESSARY TO RESET

THE UNIT BY MEANS OF LOCAL PUSH BUTTON.

A

FLAME SIMULATION

CHECK IS CONDUCTED

DURING WAITING OR PREPURGE TIME.

AFTER THE PRESET

WAITING OR PREPURGE

TIME HAS ELAPSED, THE IGNITION DEVICE IS

ACTIVATED AND VERIFIED, THEN THE PILOT

VALVE IS OPEN.

PILOT PROVING PERIOD STARTS IF THE FLAME

IS DETECTED WITHIN THE

SAFETY TIME

.

IF NO FLAME IS DETECTED DURING THE SAFETY

TIME A FAULT LOCKOUT OCCURS.

FLAME FAILURES

DURING OPERATION LEADS

TO LOCKOUT RESTART OR RECYCLE DEPENDING

ON Q512 PARAMETER SETTING.

A

SHUTDOWN REQUEST

FROM THERMOSTAT

OR LOCAL PUSH BUTTON TURNS OFF THE

BURNER, WAITING FOR ALLOWED POST-

COMBUSTION AND POSTPURGE

AN

AUTOMATIC SHUTOFF

OF THE BURNER CAN

BE ACTIVATED, AFTER A PRESET TIME OF

BURNER RUNNING. THE BURNER CAN WAIT

FOR A MANUAL RESET OR RESTART IN AUTO-

MATIC MODE.

A SELF TEST IS MADE AT EVERY RESTART. THIS

PARAMETER MAY BE SET IN THIS WAY ONLY IF

THE BURNER CAN RESTART AS INTENDED IN ALL

OPERATING PHASES.

PROGRAM SEQUENCE