© 2000 CONTRIVE • B1401|400.EN

0211

3

www.contrive.it

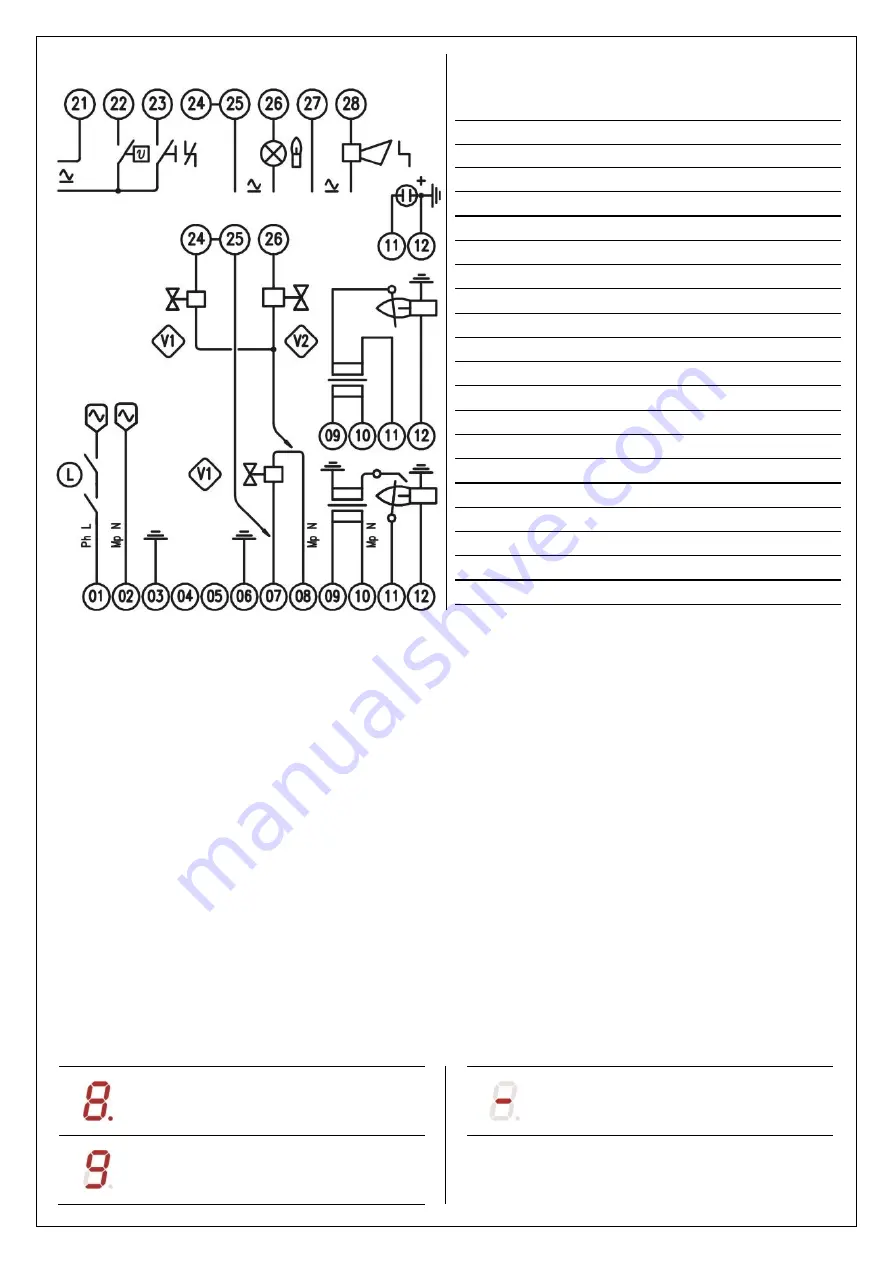

WIRING DIAGRAM

01

POWER SUPPLY PHASE

02

POWER SUPPLY NEUTRAL

03

GROUND

04

TRAXBUS INTERFACE POSITIVE (UNAVAILABLE)

05

TRAXBUS INTERFACE NEGATIVE (UNAVAILABLE)

06

GROUND

07

GAS VALVE

(

V1)

08

POWER SUPPLY NEUTRAL

09

IGNITION TRANSFORMER OUTPUT

10

POWER SUPPLY NEUTRAL

11

FLAME DETECTOR INPUT

(ROD, UV-)

12

GROUND

21

INPUTS COMMON RETURN

22

THERMOSTAT INPUT

23

RESET INPUT

24

BURNER ON CONTACT RETURN

25

BURNER ON CONTACT RETURN

26

BURNER ON CONTACT OR MAIN GAS VALVE

(V2)

27

BURNER LOCKOUT CONTACT RETURN

28

BURNER LOCKOUT CONTACT

L

EXTERNAL LIMITS

USE POWER, SIGNAL AND CONTROL CABLE SUITABLE FOR THE TYPE OF OPERATION AND COMPLYING WITH ALL REGULATIONS

DO NOT ROUTE CONNECTIONS TOGETHER WITH FREQUENCY CONVERTER CABLES OR CABLES EMITTING STRONG FIELDS

PROVIDE RELIABLE CONNECTION TO PE (PROTECTION EARTH) AND BURNER FRAME, RECOMMENDED WIRE GAUGE > 4 mm

2

ALL ELECTRONIC SYSTEMS MUST BE SUPPLIED BY A DEDICATED TRANSFORMER IN A TN-S EARTHING SYSTEM

USE UNSCREENED HIGH-VOLTAGE CABLE FOR IGNITION AND IONIZATION ROD LINES, LAYING CABLES INDIVIDUALLY, AVOIDING

METAL CONDUITS. KEEP HIGH VOLTAGE IGNITION CABLES AS SHORT AS POSSIBLE, AVOIDING LOOPS AND KEEP ALL OTHER

CABLES, ESPECIALLY THOSE OF UV OR IONIZATION ROD, AS FAR APART AS POSSIBLE

OUTPUTS AT TERMINALS 24 25 26 27 ARE SPST UNPROTECTED DRY CONTACTS, LOAD MUST BE WITHIN THE RATED CURRENT

POWER SUPPLY FUSE

The device and following burner loads are protected by means of an embedded POWER SUPPLY FUSE [7]:

TERMINAL 07 : GAS VALVE V1

TERMINAL 09 : IGNITION TRANSFORMER

This fuse must be replaced only with same type and value component: 3,15 A quickblow (5x20mm).

STATUS DISPLAY

The STATUS DISPLAY [4] gives, at any time, a clear indication about the working conditions of both the burner and

the equipment, making it easier to detect any failure occurring in the system or the device.

WARNINGS

SELF-TEST

SELF DIAGNOSIS, EVERY TIME THE UNIT IS

POWERED OR THE BURNER IS STARTED.

CONFIGURATION

UNIT IN CONFIGURATION MODE THROUGH

COMMUNICATION LINK.

LIFETIME EXPIRED

MAINTENANCE REQUIRED AFTER 500.000

IGNITIONS. PUSH AGAIN TO START ANYWAY.