441-622-015

Type 500X

Page 4

3.1 Calibration

3.2.1

Zero and Span should always be checked after mounting. If unit is calibrated in a vertical position and

then mounted at an angle, readjustment of the zero is necessary. To calibrate use the following

procedure:

1. Open protective covers to expose zero and span adjustment screws.

2. Connect the recommended air supply to the inlet of the transducer and an accurate pressure

gage to the outlet.

3. Connect the electrical input and set the input signal to the minimum value of the range being

used (e.g., 4 mA for a 4-20 mA unit).

4. Observe the output pressure. If necessary, adjust zero screw until reaching minimum output

pressure setting. Turn zero screw counterclockwise to increase pressure, clockwise to

decrease pressure.

If unable to achieve output during calibration process, turn zero adjustment

screw counterclockwise for up to 30 revolutions, until output pressure rises.

5. Increase electrical input signal to its maximum value (e.g., 20 mA for a 4-20 mA unit).

6. Observe the output pressure. If necessary, adjust the span screw until reaching maximum output

pressure setting.

For I/P (current) input models turn span screw counterclockwise to increase

pressure, clockwise to decrease pressure. For E/P (voltage) input models turn

span screw clockwise to increase pressure, counterclockwise to decrease

pressure

.

7. The Zero and Span adjustments are interactive. After adjusting the span, it will be necessary to

recheck the zero. Repeat steps 3-6 until both end points are at the required values.

8.

For reverse acting

performance interchange the black and white electrical signal leads and carry

out the same input (4mA) to get maximum output then with maximum input (20mA) to get minimum

output. Repeat as necessary. FM Approvals approved units must be ordered per specific model code.

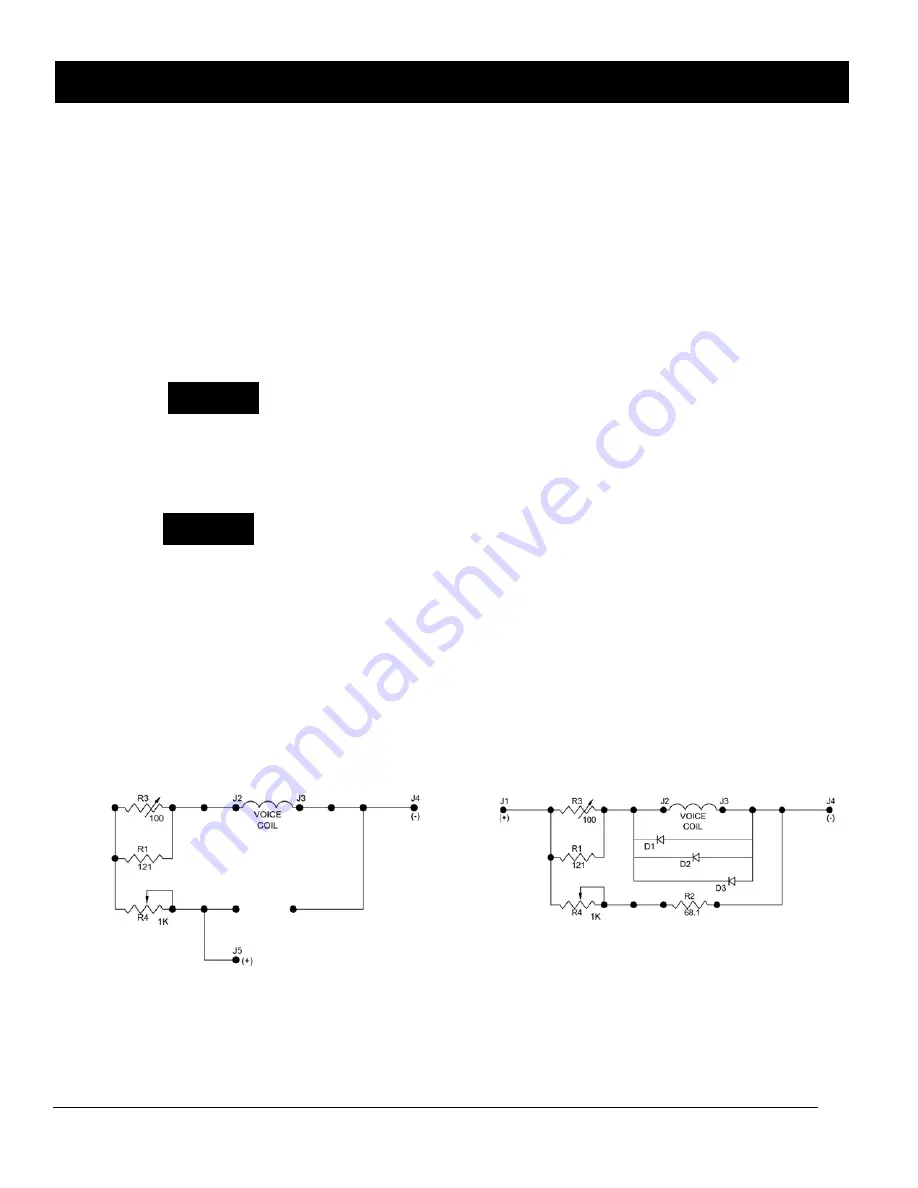

Figure 2

Electrical Schematic (E/P) Electrical Schematic (I/P)

3. OPERATION

NOTE

NOTE