3

4 5 6

1

7

2

8

3

9

L1 L2 L3

4 5 6

7 8 9

1 2

3

L1 L2 L3

Low Voltage

208/230 Volts

High Voltage

460 Volts

3 Phase, 9 Lead Motor

Y-Connection

7

1

6

7 8 9

4 5 6

1 2

3

Low Voltage

208/230 Volts

High Voltage

460 Volts

8

2

4

9

3

5

L1

L3

L2

L1

L3

L2

3 Phase, 9 Lead Motor

Delta-Connection

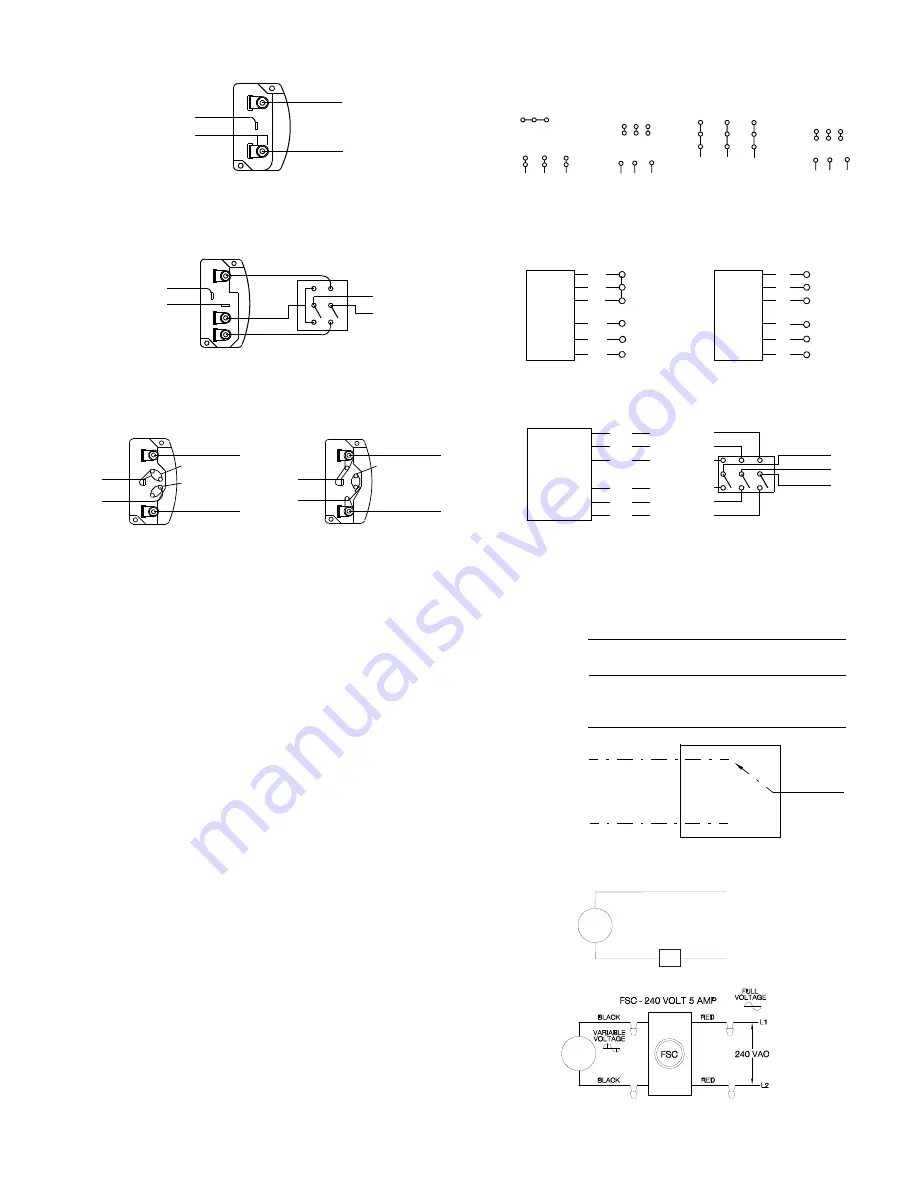

Wiring Diagrams

Wiring Diagrams

When ground is required, attach to ground A or B with no. 6 thread forming

screw. To reverse, interchange T-1 and T-4.

Ground A

L

1

L

2

Line

T-1

T-4

Ground B

Single Speed, Single Phase Motor

To reverse, interchange any 2 line leads.

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-1 and T-4 leads.

T-1

T-4

Ground B

Ground A

High Speed

Low Speed

L

1

L

2

Line

2 Speed, 2 Winding, Single Phase Motor

2 Speed, 1 Winding, 3 Phase Motor

To reverse, interchange any 2 line leads. Motors require magnetic control.

Together

Open

Low Speed

High Speed

Motor

Motor

1

2

3

4

5

6

L

1

L

2

L

3

L

1

L

2

L

3

1

2

3

4

5

6

Single Speed, Single Phase, Dual Voltage

2 Speed, 2 Winding, 3 Phase

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-5 and J-10 leads.

Link A

Low Voltage

Ground A

Ground B

T-5

J-10

L

1

L

2

Line

T-5

J-10

Ground A

Ground B

Link A & B

High Voltage

L

1

L

2

Line

Link B

To reverse: High Speed-interchange leads T

11

and T

12

.

Low Speed-interchange leads T

1

and T

2

. Both Speeds-interchange any 2

line leads.

T

3

T

2

T

1

T

11

T

12

T

13

Low Speed

Low Speed

Low Speed

High Speed

High Speed

High Speed

L

1

L

2

L

3

Motor

Line

Line

Line

Operation

Pre-Start Checks

a. Lock out all the primary and secondary power sources.

b. Inspect and tighten fasteners and setscrews, particu-

larly fan mounting and bearing fasteners. Refer to

Torque chart

.

c. Inspect belt tension and pulley alignment. Refer to

Belt

and Pulley Installation

, page 5.

d. Inspect motor wiring. Refer to

Wiring Installation

, page

2.

e. Ensure belt touches only the pulleys.

f. Rotate the wheel to ensure it rotates freely.

g. Ensure fan and ductwork are clean and free of debris.

h. Close and secure all access doors.

i. Restore power to fan.

Start Up

Turn the fan on. In variable speed units, set the fan to its

lowest speed. Inspect for the following:

• Direction of rotation

• Excessive vibration

• Unusual noise

• Bearing noise

• Improper belt alignment or tension (listen for squealing)

• Improper motor amperage or voltage

If a problem is discovered, immediately shut the fan

off. Lock out all electrical power and check for the

cause of the trouble. Refer to Troubleshooting, page 6.

VCRD with Shade Pole or PSC Motors

White

Line

Line

*

Black (High)

Red (Low)

Line

VCRD with 2-Speed PSC Motors

White

Line

NOTE: Insulate Unused Lead

*

Black

*See VCR Wiring Diagram for correct lead.

†

Locate away from heat.

VCR

FAN*

WHITE

BLACK

FSC - 115 VOLT 10 AMP

FSC

VCR

FAN*