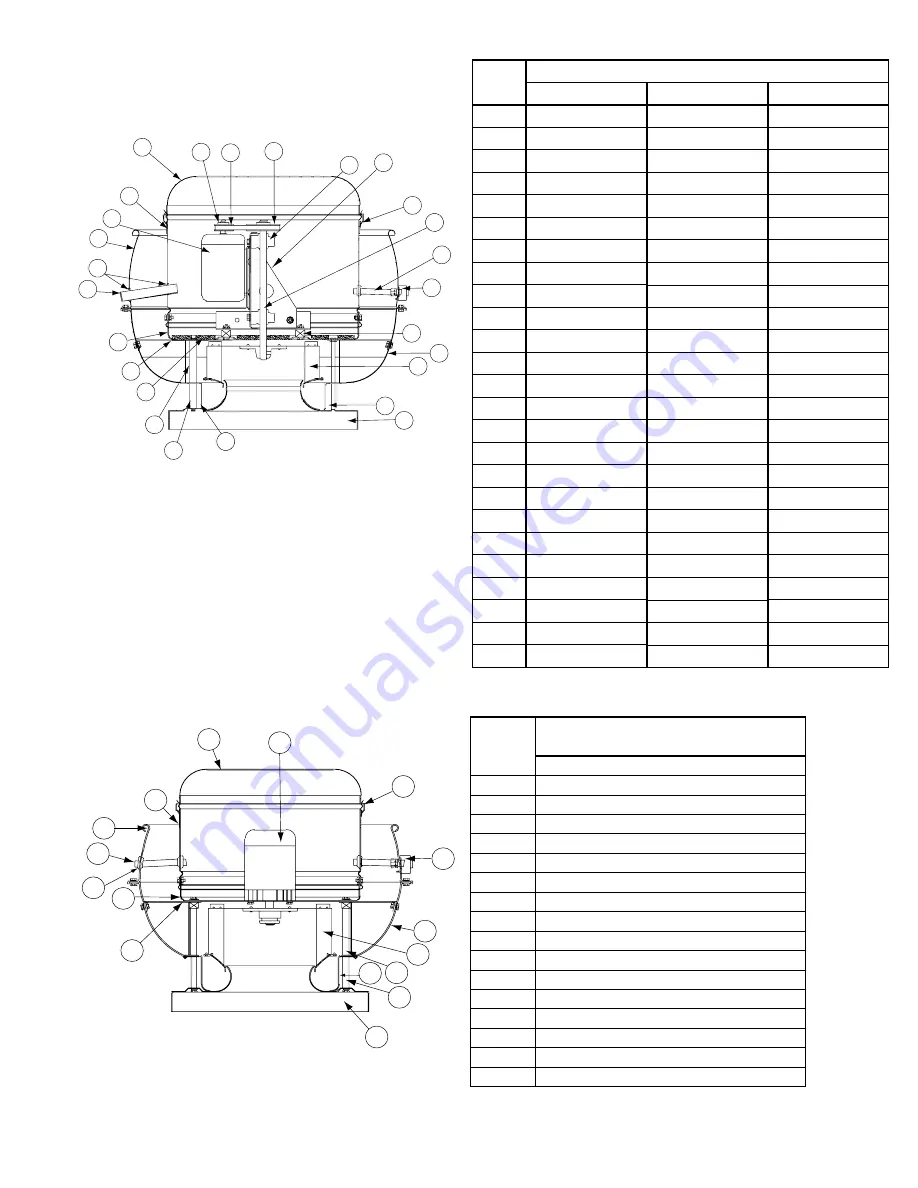

7

Part

No.

VCRD/VCRD-HP/VCRD-XP Parts Description

100-195

1a

Top Cap Lid

1b

Top Cap Cylinder

2

Top Cap Clip (4)

3

Motor

4

Spun Motor Plate

5

Baffle

6

Wheel Assembly

7

NEMA 3 Junction Box

8

Base

9

Conduit

11

Upper Post (4)

12

Lower Post (4)

13

Wind Band

14

Brace (4)

15

Vent Tube (2)

16

Grommet (4)

2

5

12

11

8

14

3

4

15

13

6

1a

1b

7

16

9

Part

No.

VCR/VCR-HP/VCR-XP Parts Description

100-225

245

270-490

1a

Top Cap Lid

Top Cap Lid

Top Cap Lid

1b

Top Cap Cylinder

Top Cap Cylinder

Top Cap Cylinder

2

Top Cap Clip (4)

Top Cap Clip (4)

Top Cap Clip (8)

3

Motor

Motor

Motor

4

Spun Motor Plate

Spun Motor Plate

Spun Motor Plate

5

Baffle Baffle

Baffle

6

Wheel Assembly

Wheel Assembly

Wheel Assembly

7

Base

Base

Base

8

Conduit

Conduit

Conduit

9

Isolator (4)

Isolator (4)

Isolator (4)

10

Upper Post (4)

Upper Post (4)

Upper Post (8)

11

Lower Post (4)

Lower Post (4)

Lower Post (8)

12

Wind Band

Wind Band

Wind Band

13

Brace (4)

Brace (4)

Brace (8)

14

Power Assembly

Power Assembly

Power Assembly

15

Shaft Shaft Shaft

16

Bearing (2)

Bearing (2)

Bearing (2)

17

Drive Sheave

Drive Sheave

Drive Sheave

18

Driven Sheave

Driven Sheave

Driven Sheave

19

Belt Set

Belt Set

Belt Set

20

Vent Tube

Vent Tube

Vent Tube

21

Grommet (2)

Grommet (2)

Grommet (2)

22

—

Cut Off (HP & XP Only ) Cut Off (HP & XP Only )

23

Insulation

Insulation

Insulation

24

NEMA 3 Junction Box

NEMA 3 Junction Box NEMA 3 Junction Box

Parts List

VCR/VCR-HP/VCR-XP Parts

6

8

22

7

5

9

24

15

2

14

16

18

19

17

1a

1b

3

12

20

4

13

23

10

9

11

21

VCRD/VCRD-HP/VCRD-XP Parts