13.

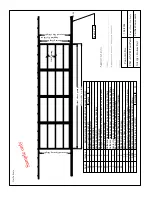

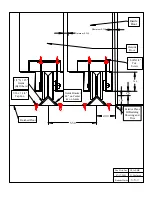

Turn the door panel over

and place one tek per joint.

14.

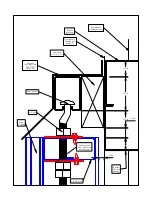

Determine location of top guide pin on top rail

. Drill ½” hole for guide pin. On

Doors with a single top rail girt a Trolley Support Bracket (2-3/8 X 4” drilled flat

plate) is supplied. This is installed on top and bottom at each hole drilled in top

rail using assembly tek screws. This is not required on doors with two or more top

rail girts.

15.

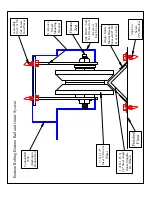

Insert top guide pins in top rail

. Secure with one nut on top and two under the

top rail. This pin can be rotated to adjust door to opening.

16.

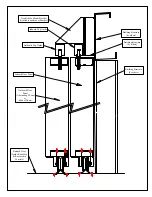

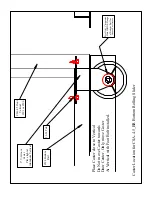

Insert

bottom casters

in bottom rail per drawings using assembly tek screws. If

Foot bolts are supplies see the installation notes for the location of the caster at

each foot bolt. Grease Zerk fitting is installed on the axle. This must face the rear

of the door as installed in the opening. Drill a 1” diameter access hole in the rear

flange of the bottom rail to service the Grease fitting.

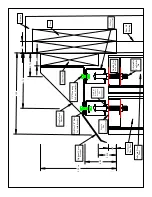

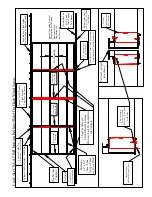

17.

Stand door up

and slide door on bottom track and guide tip pin into top track

from each side of opening.

18.

Install a

Jamb latch

at each side of opening.

19.

Install a

Center chain latch

between panels on multiple panel systems

20.

Foot Bolts

are optionally supplied and are installed internally towards the center

of the opening. When supplied, the caster will have to be located far enough away

from the vertical to allow the foot bolt to move freely. Install the foot bolt to miss

the bottom guide. Drill a minimum ¾” hole 1” deep in the floor for the foot bolt.

Door maintenance:

1.

Grease each caster with wheel bearing grease annually. More often in dust

areas and when the door is used frequently.

2.

Check security of the top guide pins and tighten or replace if showing wear.

3.

Check top guide track for wear and replace if needed. The top guide pin slides

in the top guide track and the track groove can be lubricated with grease if

desired.

4.

Check the security of the bottom guide. Retighten or replace attachment

screws as necessary. Replace worn bottom guide rails as needed.

Manufactured and distributed under license by:

:

R

CANNON BALL HNP