P54

P55

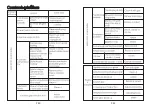

ATV-3050B Main specs (2)

3.14 Clutch type........................................

3.15 Transmission.....................................

3.16 Carbrator no.....................................

3.17 Carburator tvpe................................

3.18 Spark plug no....................................

3.19 Spark plug space...............................

3.20 Vent-pipe type..................................

3.21 Borex Stroke.....................................

3.22 Fuel tank capaciry.............................

4. Operating system

4.1 Suspension system

a)suspension front....................................

b)suspension rear.....................................

4.2 Shock absorber type

a)shock absorber front.............................

b)shock absorber rear...............................

4.3 Tire specs pressure

a)tires front...............................................

b)tires rear................................................

5. Brakes system

a)brakes front...........................................

b)brakes rear.............................................

6. Electrical Equipment

6.1 Front light...........................................

6.2 Generator............................................

6.3 Battery................................................

6.4 Rear light.............................................

Auto clutch

chain

PZ20

Plunger

D7TC

0.6-0.7

buffer

47×41.5mm(70cc) 47×49.5mm(90cc)

52.4×49.5mm(110cc) 52.4×57(125cc)

2.4L

traverse double-arm

non-indeqendent suspension

hydraulic spring

hydraulic spring

145/70-6=10~24Psi 16×8-7=10~24Psi(pressure)

145/70-6=10~24Psi 16×8-7=10~24Psi(pressure)

Mechanical hub brake/hand

manipulating patterns

Hydraulic disc/ foot

manipulating patterns

12V21V5W

non-contact outside the rotor flywheel

12V4AH / 12V5AH

12V21 / 5W

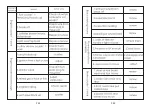

Spark Arrestor Screen (Maintenance)

Required maintenance and cleanout:

1. After every 100 hours of operation the

muffler should be

cleaned by removing the clean

out bolt by using a 6.0mm Allen wrench.

2. After every 60 hours of operation the Spark

Arrester has to be cleaned by loosening the

retaining nut using a 6.0mm Allen wrench. Using

pliers turn the sleeve of the Spark Arrester

counterclockwise and pull out. Clean the screen

with an exhaust cleaning solution and replace,

securing it by tightening the retaining nut.

3. After every 200 hours of operation the Spark

Arrester has to be replaced by loosening the

retaining nut using a 6.0mm Allen wrench. Using

pliers turn the sleeve of the Spark Arrester

counterclockwise and pull out. Replace a new

Spark Arrester and secure it by tightening the

retaining nut.